Multi-flow-directional filtering device used for range hood

A filtering device and a range hood technology are applied in the fields of removing oil fume, applications, and household stoves, etc., which can solve the problems of less number of changes in direction and insufficient collision of oil fume, and achieve the effect of improving the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

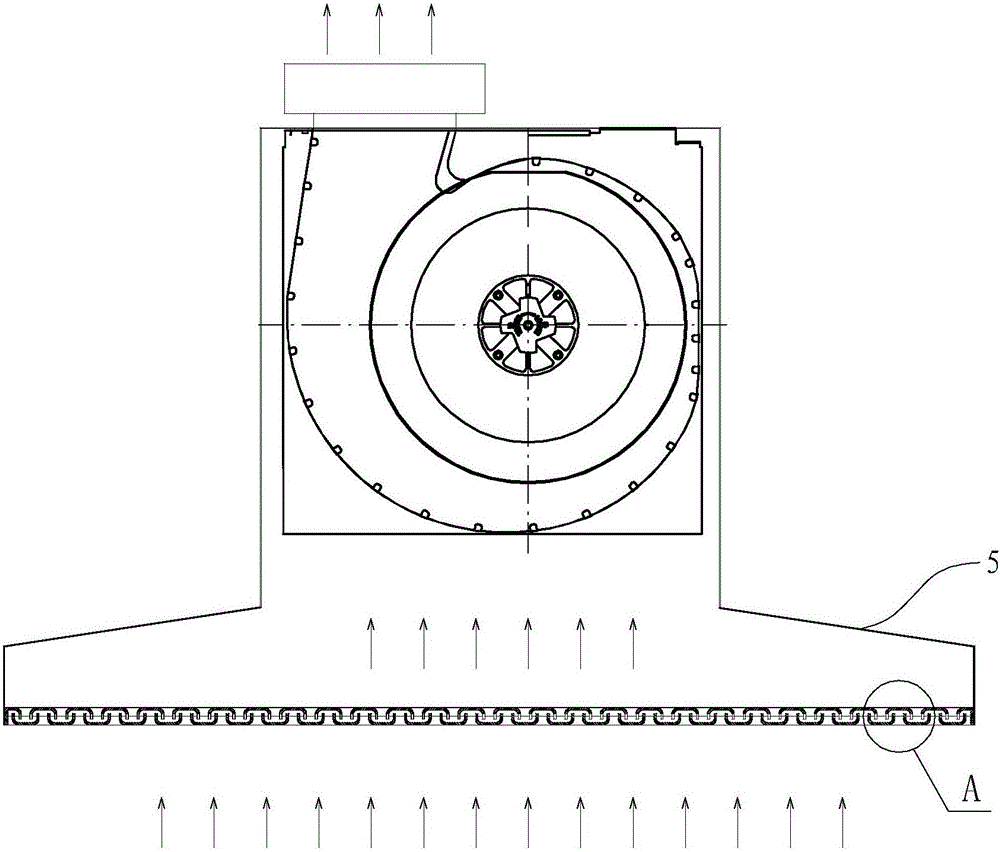

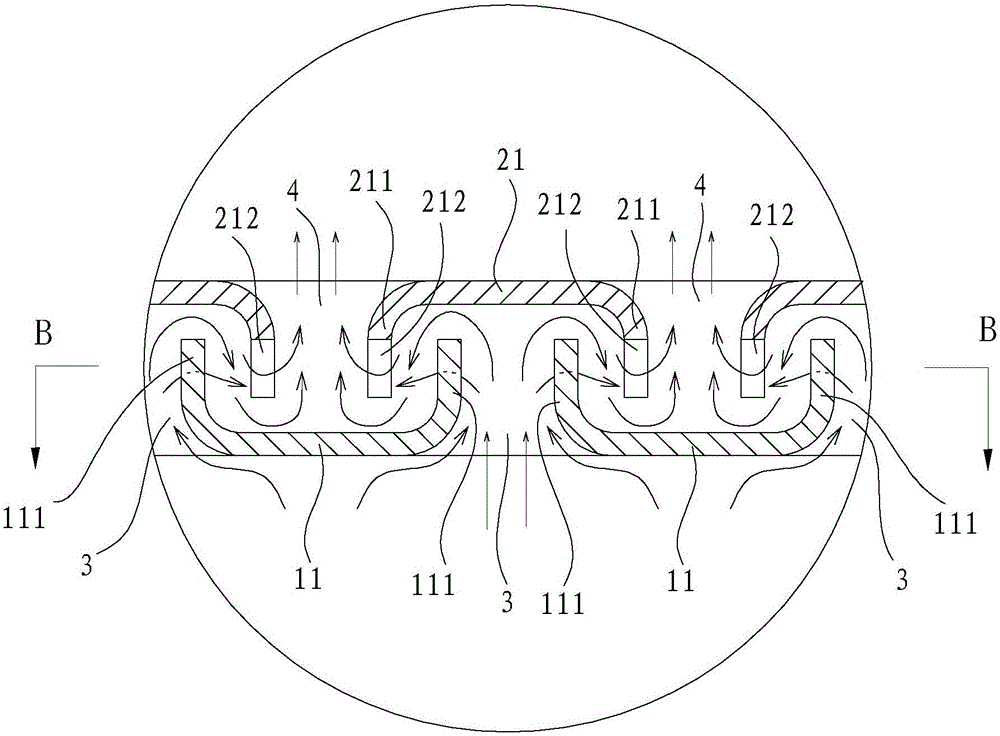

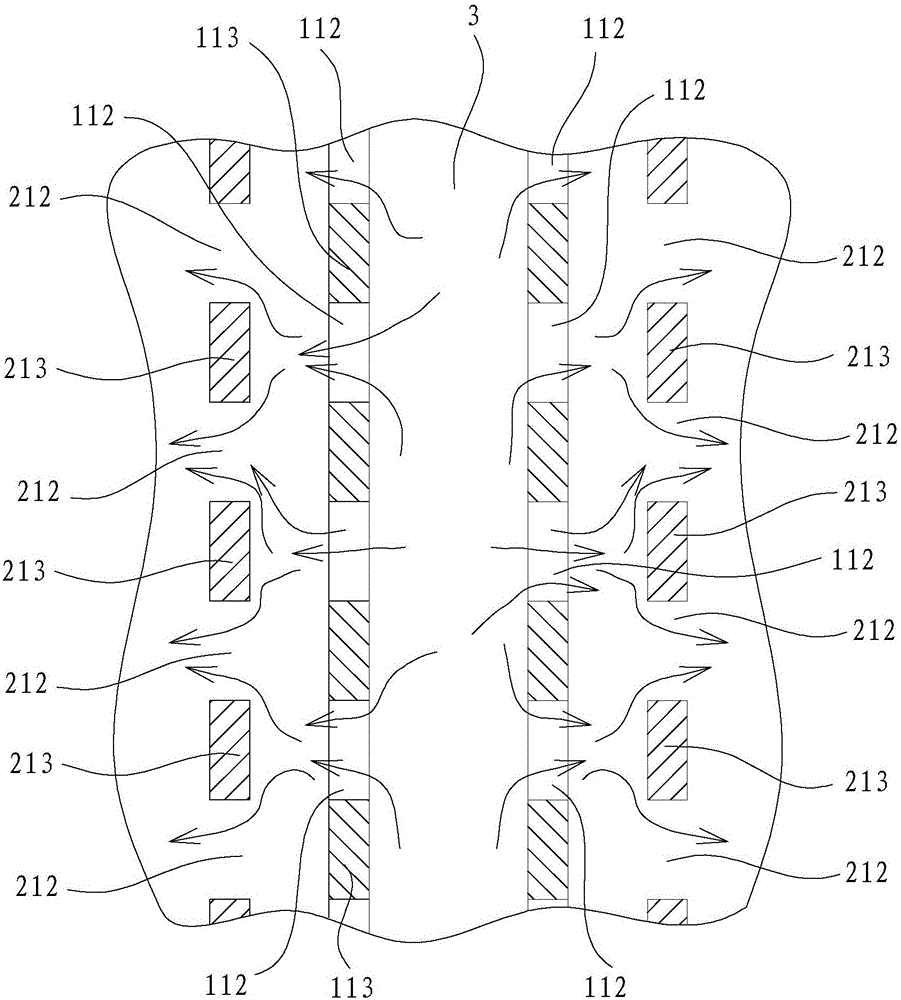

[0029] like Figure 1 to Figure 8 As shown, the multi-flow filter device for a range hood in this embodiment includes a lower filter layer 1 and an upper filter layer 2, such as figure 1 As shown, the filter device is installed horizontally on the hood 5 of the range hood. Figure 4 middle arrow C and Image 6 The direction indicated by the middle arrow D is forward for description.

[0030] In this embodiment, the lower filter layer 1 includes a plurality of lower filter units 11 arranged side by side and at intervals, and the gap between two adjacent lower filter units 11 is the soot inflow inlet 3 . The upper filter layer 2 includes a plurality of upper filter units 21 which are arranged side by side at intervals, and the gap between two adjacent upper filter units 21 is the soot outlet 4 . The lower filter unit 11 and the upper filter unit 21 are arranged inversely to each other, and a direction change channel is formed between the lower filter unit 11 and the upper fil...

Embodiment 2

[0037] like Figure 11 As shown, the first gap of the lower filter unit of the filter device in this embodiment and the second gap of the upper filter unit are rectangular gap a, and the rest of the structure and working principle are the same as those in the first embodiment, and will not be expanded here. describe.

Embodiment 3

[0039] like Figure 12 As shown, the first gap of the lower filter unit of the filter device in this embodiment and the second gap of the upper filter unit are the triangular gap b, and the other structures and working principles are the same as those in the first embodiment, and will not be expanded here. describe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com