Silicon-based gas sensitive chip with integrated temperature and humidity sensor and manufacturing method thereof

A humidity sensor, gas-sensitive technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problem of no integrated gas-sensing unit, and achieve the effect of small size, good process compatibility and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

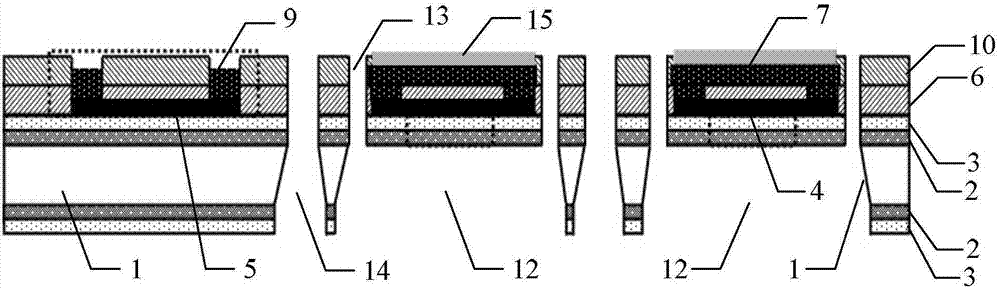

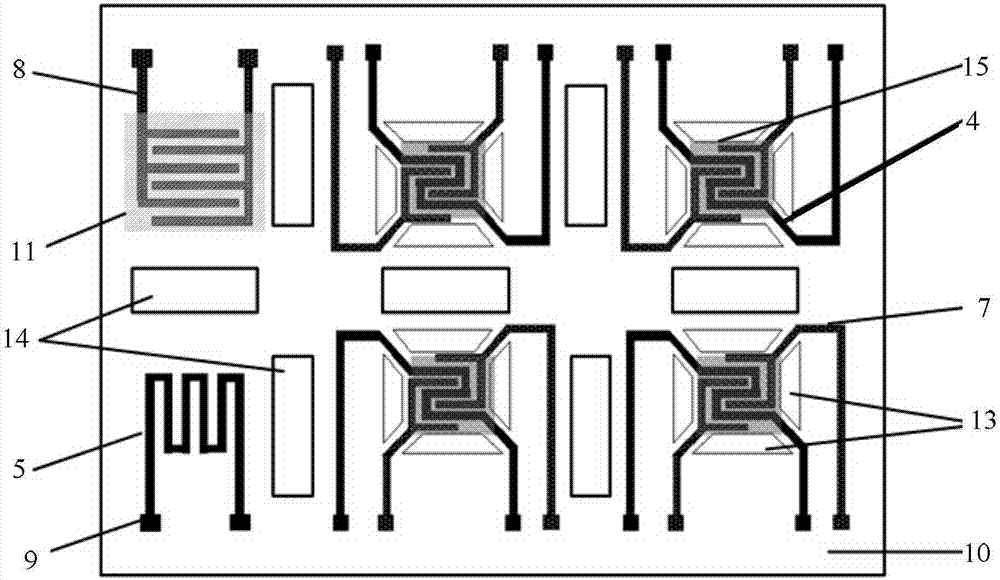

[0022] Specific implementation mode one: the following combination figure 1 , figure 2 and Figure 4 Describe this embodiment mode, the silicon-based gas sensitive chip of integrated temperature and humidity sensor described in this embodiment mode, wherein a plurality of gas sensing units, temperature sensing units and humidity sensing units are all integrated in one N-type (100) single crystal silicon chip Above, a plurality of gas sensing units form an M×N array, M represents the total number of types of gas sensing materials, and N represents the number of gas sensing elements made of each gas sensing material;

[0023] Thermal isolation through holes are arranged between the plurality of gas sensing units, temperature sensing units and humidity sensing units as second-level heat-insulating through-holes, the cross-section of the second-level heat-insulating through-holes is rectangular, and the rectangular The four corners of the arc transition are adopted.

[0024] I...

specific Embodiment approach 2

[0030] Specific implementation mode two: the following combination figure 1 , figure 2 and image 3 Describe this embodiment mode. This embodiment mode further defines the silicon-based gas-sensing chip integrated with the temperature and humidity sensor described in Embodiment 1. In this embodiment mode, in the gas sensing unit, each two adjacent electrode leads Each of them is provided with thermal isolation through holes as the first-level heat-insulation through-holes. The cross-section of the first-level heat-insulation through-holes is trapezoidal, and the four corners of the trapezoidal transitions are all made of circular arcs.

[0031] The gas sensing unit is a semiconductor structure of a silicon micro-heating plate, which mainly includes a hollow silicon cup and a micro-heating plate sensing unit formed on it, and the micro-heating plate sensing unit uses silicon dioxide and silicon nitride as a supporting layer, On the support layer are heating electrode leads a...

specific Embodiment approach 3

[0032] Specific implementation mode three: Figure 1 to Figure 4 The specific process of the manufacturing method of the silicon-based gas-sensitive chip integrated with the temperature and humidity sensor described in this embodiment is as follows:

[0033] Step 1. Fabricate a silicon dioxide layer on one surface of the N-type single crystal silicon wafer, and fabricate a silicon nitride dielectric layer on the surface of the silicon dioxide layer, and the silicon dioxide layer and the silicon nitride dielectric layer constitute an induction module (a unit capable of sensing on silicon nitride can be called a sensing module) supporting layer;

[0034] Step 2, making a plurality of heating resistors of the gas-sensing unit and sensitive resistors of the temperature-sensing unit above the support layer, and the plurality of heating resistors form an M×N array;

[0035] Step 3, depositing silicon dioxide or silicon nitride on the support layer as a first insulating passivation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com