CAN (Controller Area Network) bus remote monitoring system based on electric heat tracing liquid indicator

A remote monitoring system and CAN bus technology, applied in the field of liquid level gauges, can solve the problems of not being able to understand the liquid level of on-site equipment in real time, making it difficult to ensure safe and reliable operation of production, and not having remote monitoring functions, etc., to achieve flexible and convenient control methods, Stable and reliable performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

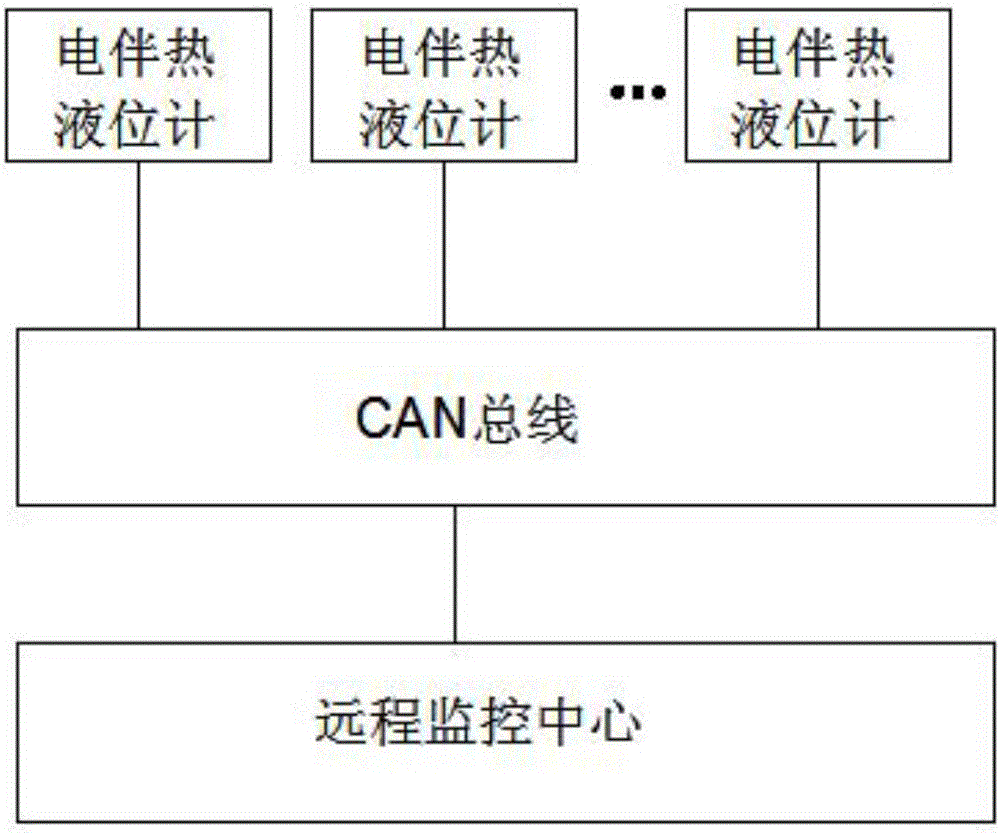

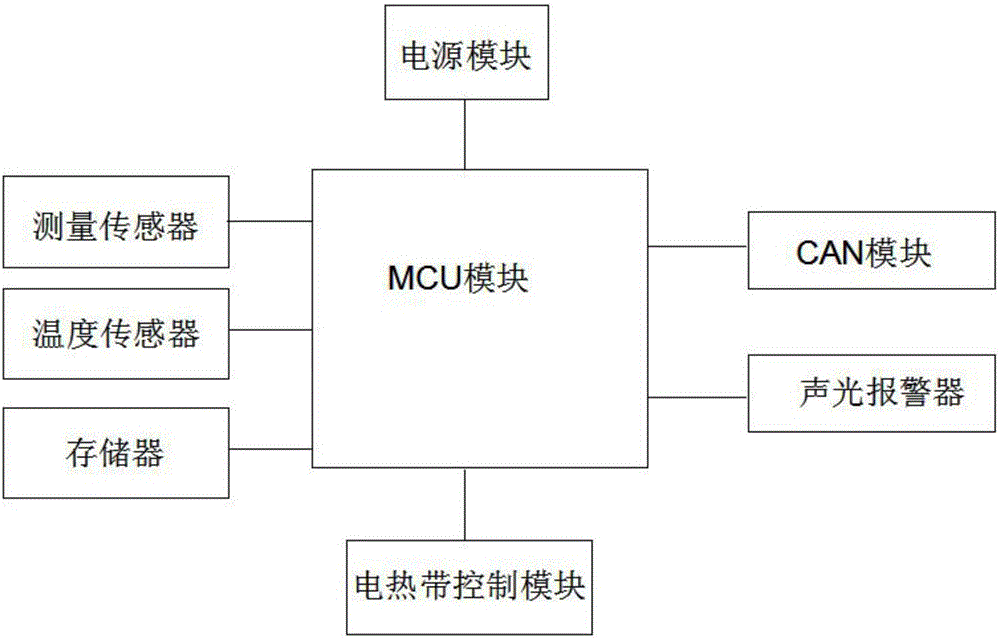

[0017] A CAN bus remote monitoring system based on electric heating liquid level gauge, such as figure 1 As shown, including electric heat tracing level gauges installed on different field devices, CAN bus and remote monitoring center, multiple electric heat tracing level gauges are connected to the remote monitoring center through CAN bus, this electric heat tracing level gauge The monitoring data is transmitted by connecting with the remote monitoring center through the CAN bus, and the remote monitoring center can also send control commands to the electric heating level gauge to control the work of the electric heating level gauge in real time. This monitoring system adopts the CAN bus mode in the existing system, which can avoid the capital investment brought by the construction of the communication network.

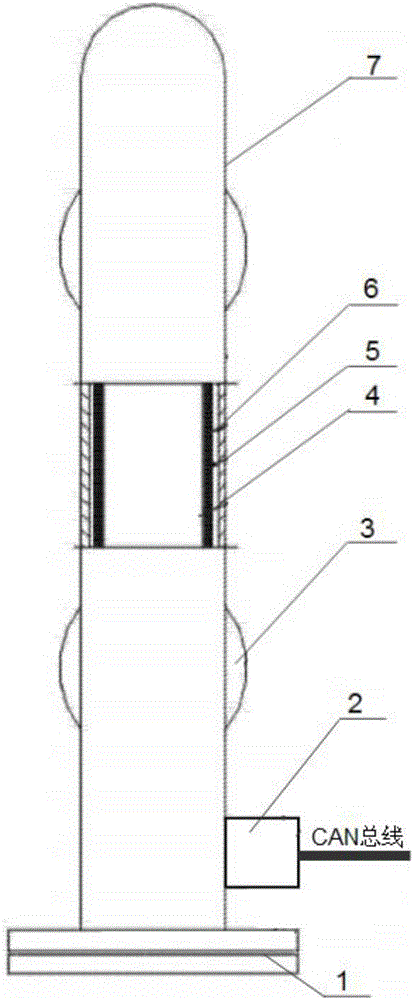

[0018] like figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com