Remote wireless monitoring system based on infrared quartz glass tube liquid level gauge

A quartz glass tube and remote wireless technology, applied in the field of liquid level gauges, can solve the problems of not being able to understand the liquid level of on-site equipment in real time, untimely handling of unexpected situations, and lack of remote monitoring functions, etc., to achieve flexible, convenient and accurate control methods Display, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

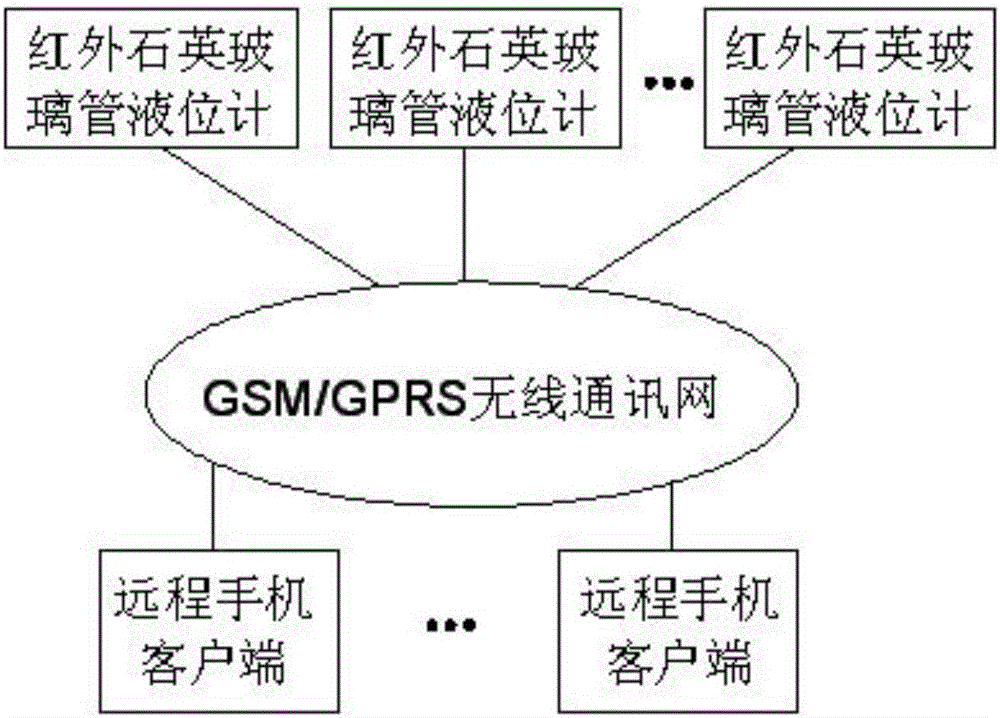

[0019] A remote wireless monitoring system based on infrared quartz glass tube liquid level gauge, such as figure 1 As shown, including infrared quartz glass tube liquid level gauges installed on different field devices, wireless communication network and remote mobile phone client, multiple infrared quartz glass tube liquid level gauges are connected to multiple remote mobile phone clients through wireless communication networks. The infrared quartz glass tube liquid level gauge is connected to the remote mobile phone client of the monitoring personnel through the wireless communication network to transmit monitoring data. In this embodiment, the wireless communication network adopts the GSM / GPRS wireless communication network, and the capital investment brought by the construction of the communication network can be avoided through the public com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com