Atmosphere corrosion acceleration test method

An accelerated test and atmospheric corrosion technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of insufficient consideration of the degree of action, single corrosion factor, and insufficient comprehensiveness, etc., to achieve convenient operation and experimental results Good, simulated and accelerated effects

Inactive Publication Date: 2016-09-07

GUANGDONG OCEAN UNIVERSITY

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are still the following problems: 1. The factors considered by the test device are still not comprehensive enough. The corrosion factor considered in the acceleration method is relatively single, and the cycle is long, which brings a lot of inconvenience to the test personnel; 2. The corrosion acceleration still stays at the level of indoor simulation In fact, although it can r

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

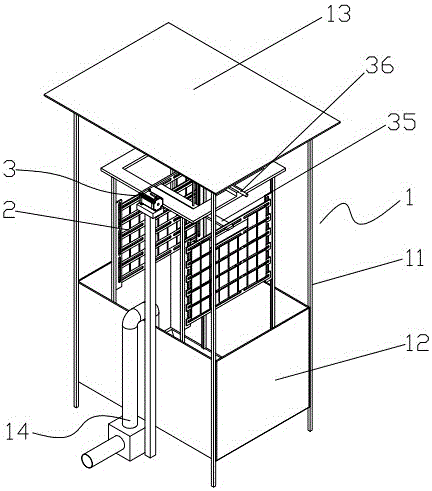

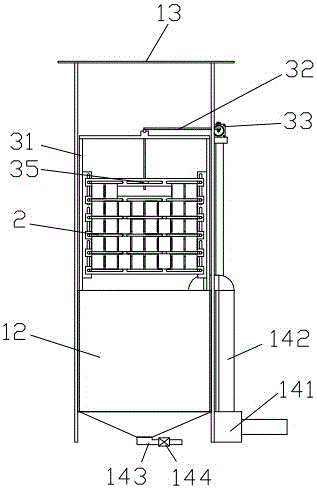

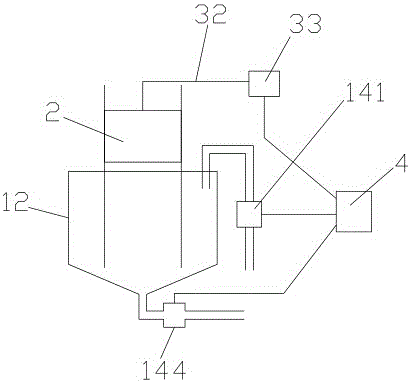

The invention discloses an atmosphere corrosion acceleration test method which comprises the following steps: firstly, designing an acceleration test device; then linearly cutting and grinding a test sample, and fixing the test sample on a test hanging rack of the acceleration test device. During test, a controller controls a water feeding and drainage mechanism to work to fill a water storage tank with seawater, and a dry-wet circulating corrosion test is carried out, and comprises the following procedures: the controller controls a hanging rack lifting device to put the test hanging rack into the seawater in the water storage tank for soaking for T1, and the test hanging rack rises for drying in air for T2; finally, the procedures of the dry-wet circulating corrosion test are repeated till reaching a specified test period; and upon completion of the acceleration test, the sample is analyzed for corrosion. The atmosphere corrosion acceleration test method is convenient to operate; the corrosion acceleration test is carried out outside; a test environment is a natural environment, and the seawater is actually used as a corrosion acceleration medium, so that the simulation property and the acceleration speed for ocean and atmosphere corrosion processes are high; furthermore, the dry-wet circulating period can be adjusted according to corrosion characteristics of different materials; and on the basis that the corrosion progress is not changed, the acceleration speed is increased.

Description

technical field [0001] The invention relates to the field of test technology for simulating atmospheric environment accelerated corrosion, in particular to an accelerated test method for atmospheric corrosion. Background technique [0002] Mechanical engineering equipment has been working in various atmospheric environments for a long time. The unavoidable problem in the service process is the failure of atmospheric corrosion of materials. According to statistics, the economic losses caused by atmospheric corrosion account for more than half of the total corrosion losses. Therefore, it is an important and urgent task to study the corrosion phenomenon and law of materials in the atmosphere and to understand the influence of environmental factors on material corrosion. [0003] The research method of metal corrosion failure in the atmospheric environment is the natural exposure experiment, which is a more reliable corrosion research method close to the use environment. The mat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/00

CPCG01N17/006

Inventor 王贵文成田玉琬胡杰珍陈世亮

Owner GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com