Flexible hair sensor based on ferromagnetic microfilaments and applications thereof

A sensor and microwire technology, applied in the sensor field, can solve the problems of limited application field, complex structure, inability to directly test contact stress or vibration, etc., to achieve high sensitivity and stability, excellent mechanical properties, cyclability and corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

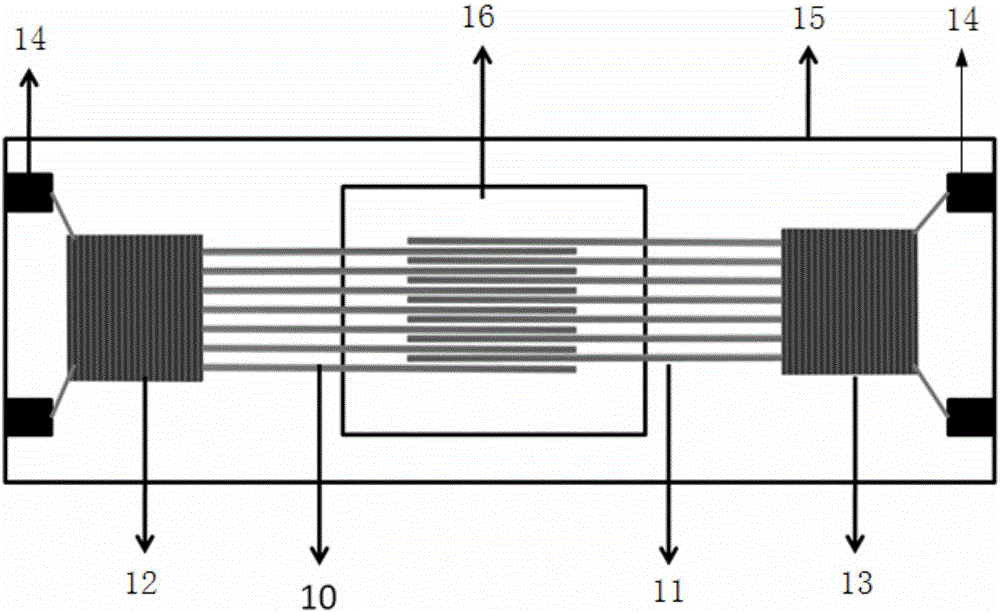

[0022] Embodiment 1: The flexible hair sensor based on ferromagnetic microwires in this embodiment includes a plurality of ferromagnetic microwires, a coil and a substrate 15, and the plurality of ferromagnetic microwires are respectively arranged in parallel and at intervals to form the first ferromagnetic microwire array 10 and The second ferromagnetic microwire array 11, one end of the first ferromagnetic microwire array 10 and one end of the second ferromagnetic microwire array 11 are arranged to cross each other and suspended, at the other end of the first ferromagnetic microwire array 10 A coil with an alternating current signal is wound on it as the excitation end 12, and the other end of the second ferromagnetic microwire array 11 is wound with a coil as the detection end 13, and the first ferromagnetic microwire array 10 is wound with one end of the coil and One end of the second ferromagnetic microwire array 11 wound with a coil is fixed on the substrate 15 .

[0023...

specific Embodiment approach 2

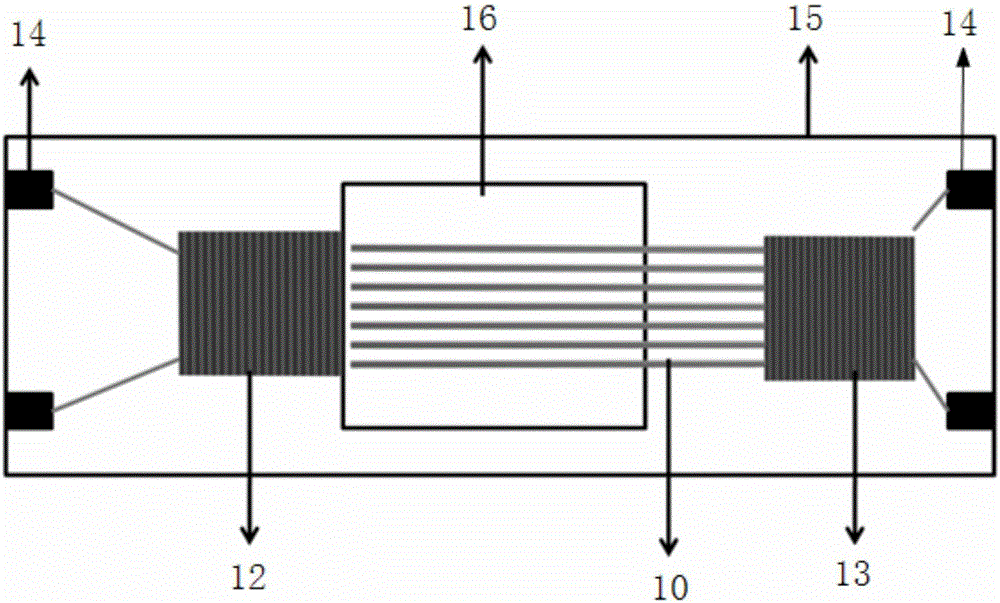

[0026] Embodiment 2: The flexible hair sensor based on ferromagnetic microwires in this embodiment includes a plurality of ferromagnetic microwires, a coil and a substrate 15, and a plurality of ferromagnetic microwires are arranged in parallel to form a ferromagnetic microwire array 10, which is supplied with an alternating current. The coil of the signal is used as the excitation terminal 12, and one end of the ferromagnetic microwire array 10 is suspended in the air and has a gap with the excitation terminal 12, and a coil is wound on the other end of the ferromagnetic microwire array 10 as the detection terminal 13, and the ferromagnetic microwire array One end of 10 wound with a coil is fixed on the base plate 15 .

[0027] The ferromagnetic microwires in the ferromagnetic microwire array of this embodiment can be arranged closely or spaced apart from each other. The space for the ferromagnetic microwire array to move freely is given by the setting of the gap.

specific Embodiment approach 3

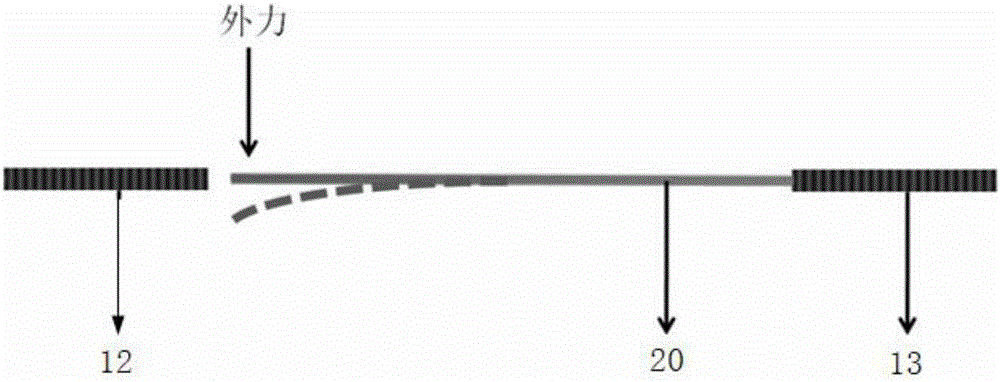

[0028] Specific embodiment three: the flexible hair sensor based on ferromagnetic microwire in this embodiment comprises a single ferromagnetic microwire 20 and a coil. There is a gap with the excitation end 12 , and a coil is wound on the other end of the single ferromagnetic microwire 20 as the detection end 13 .

[0029] In this embodiment, the space for the ferromagnetic microwire array to move freely is provided by setting the gap.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap