Spent fuel storage cell

A technology of spent fuel and neutron, which is applied in the field of spent fuel storage to achieve the effect of ensuring criticality safety, good interchangeability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

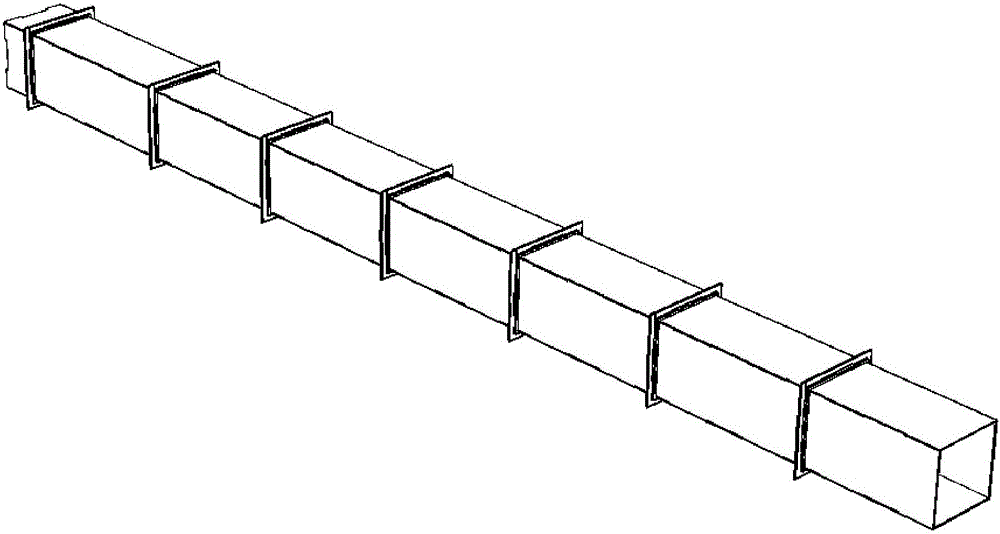

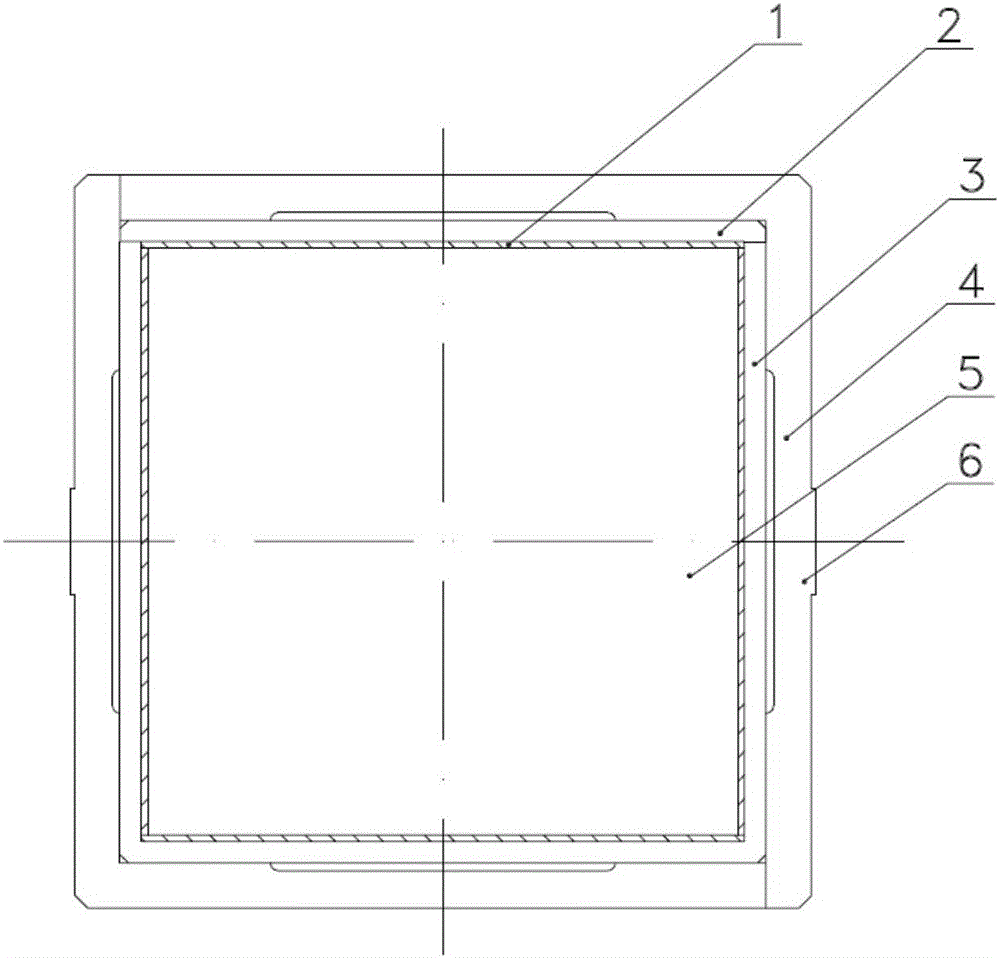

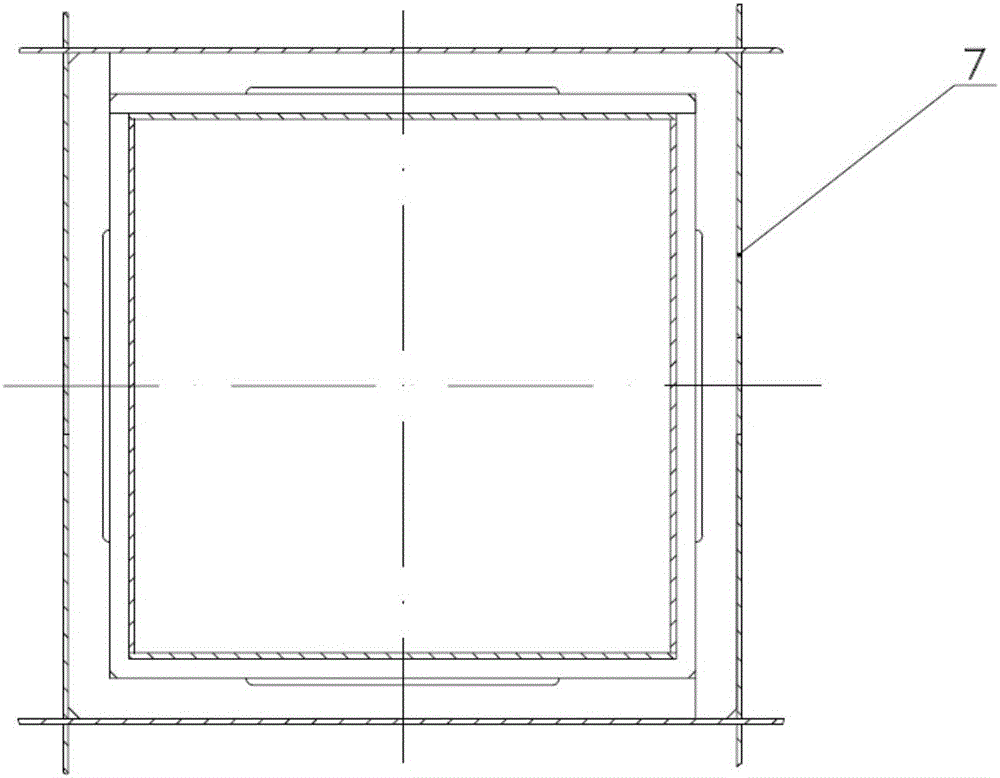

[0024] Such as Figure 1-2 Shown is the spent fuel storage chamber provided by the present invention. The storage chamber is used for storing square spent fuel assemblies. The storage chamber includes a neutron poison layer, a clamping layer and a supporting layer in sequence from the inside to the outside.

[0025] The neutron poison layer is an empty storage cavity 5 for placing spent fuel assemblies surrounded by four neutron poison plates 1. The height of each neutron poison plate 1 can cover the height of the active section of the spent fuel assembly. Both sides of the poison plate 1 along the height direction are processed into a zigzag shape, and the edges of two adjacent neutron poison plates 1 are tenon-jointed. With such a connection structure, on the one hand, it can prevent the neutron poison plate from movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com