Method for replacing working motors in power plants with synchronous motors

A technology of synchronous motors and working motors, which is applied in the direction of AC network voltage adjustment and reactive power compensation, and can solve the problems of unit safety performance degradation and excessive fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0027] The gist of the present invention is to find that during the operation of the existing synchronous generator, due to the use of asynchronous motors as the factory work The electric motor has the problem that the fluctuation range of the busbar voltage used in the power plant is too large, which leads to the decrease of the safety performance of the unit. The invention provides a method for replacing the working motor in the power plant with a synchronous motor to solve the above problems.

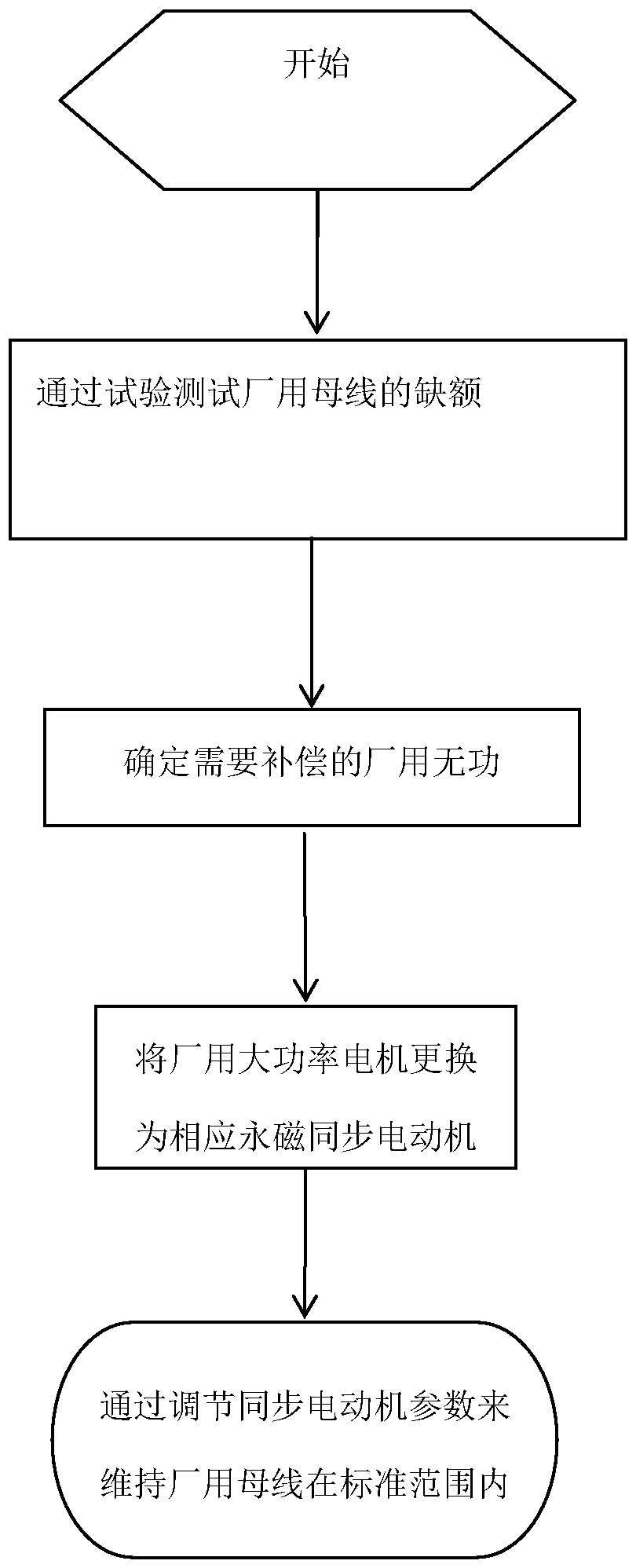

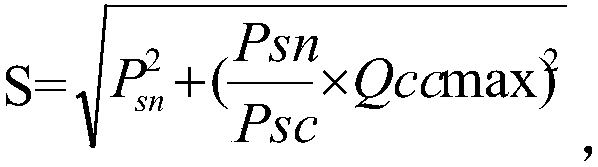

[0028] see figure 1 , the present invention replaces the working motor of the power plant with a synchronous motor. The adjustable synchronous motor is used as the relevant parameters of the factory working motor, and then by adjusting the excitation of the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com