Multi-directional vibration responded energy collector

A vibration energy harvesting, multi-directional technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as high operating frequency and inability to collect vibration energy. Achieve high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A multi-directional response vibration energy harvester includes a bracket, a cover plate is arranged above the bracket, a bottom plate is arranged below the bracket, and at least three folded piezoelectric beams are arranged inside the bracket. The folded piezoelectric beam is made of piezoelectric material, electrodes with different polarities are arranged on both sides of the folded piezoelectric beam, and the electrodes are connected with a power management circuit. There is a distance between the bent parts of the folded piezoelectric beam, and the distance can make the folded piezoelectric beam produce piezoelectric effect. The two ends of the folded piezoelectric beam are a fixed end and a cantilever end, the fixed end of the folded piezoelectric beam is fixed on the support, and the cantilever end of the folded piezoelectric beam extends to the middle of the support. A sphere is arranged in the space surrounded by the cantilever ends of the folded piezoelectric ...

Embodiment 2

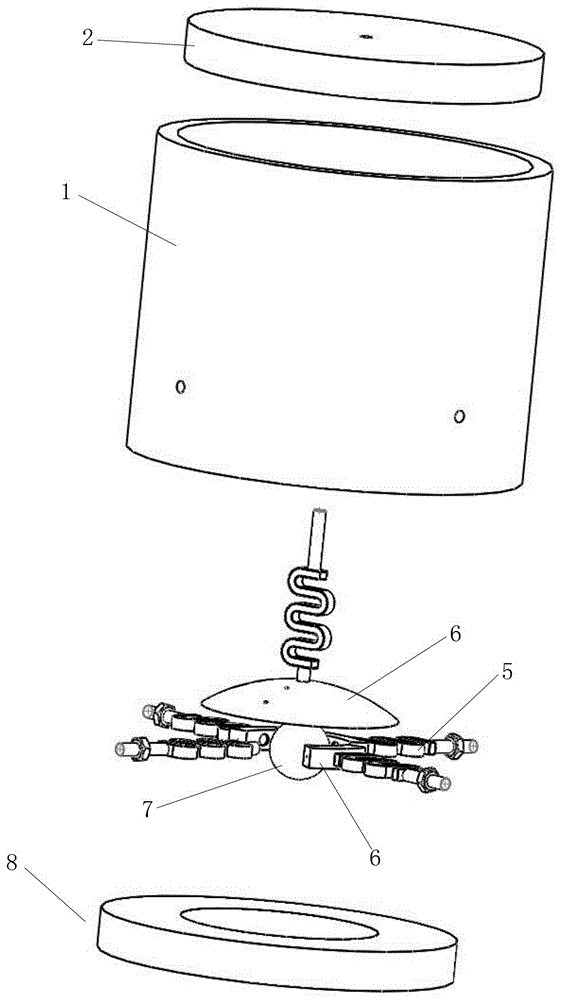

[0029] A multi-directional response vibration energy harvester comprises a bracket 1, a cover plate 2 is arranged above the bracket 1, and a bottom plate 3 is arranged under the bracket 1. There are at least three evenly distributed folded piezoelectric beams 5 inside the bracket 1 , electrodes with different polarities are arranged on both sides of the folded piezoelectric beams 5 , and the electrodes are connected to the power management circuit. There is a gap between the bending parts of the folded piezoelectric beam 5, the two ends of the folded piezoelectric beam 5 are fixed ends and cantilever ends, the fixed end of the folded piezoelectric beam 5 is fixed on the support, and the cantilever of the folded piezoelectric beam 5 The end extends to the middle of the bracket, and a sphere 7 is arranged in the space surrounded by the cantilever end of the folded piezoelectric beam 5 . The folded piezoelectric beams 5 are evenly distributed, on the one hand, it can improve the ...

Embodiment 3

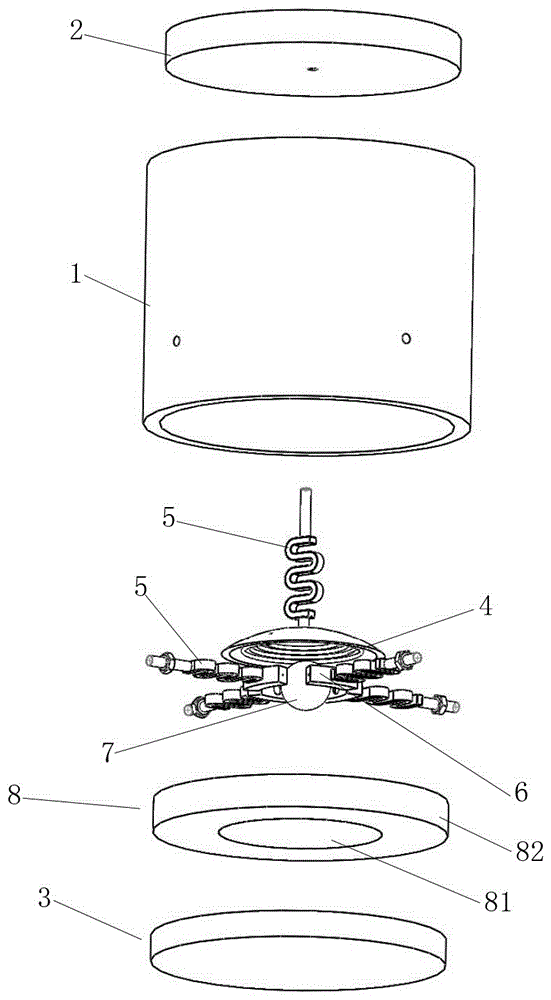

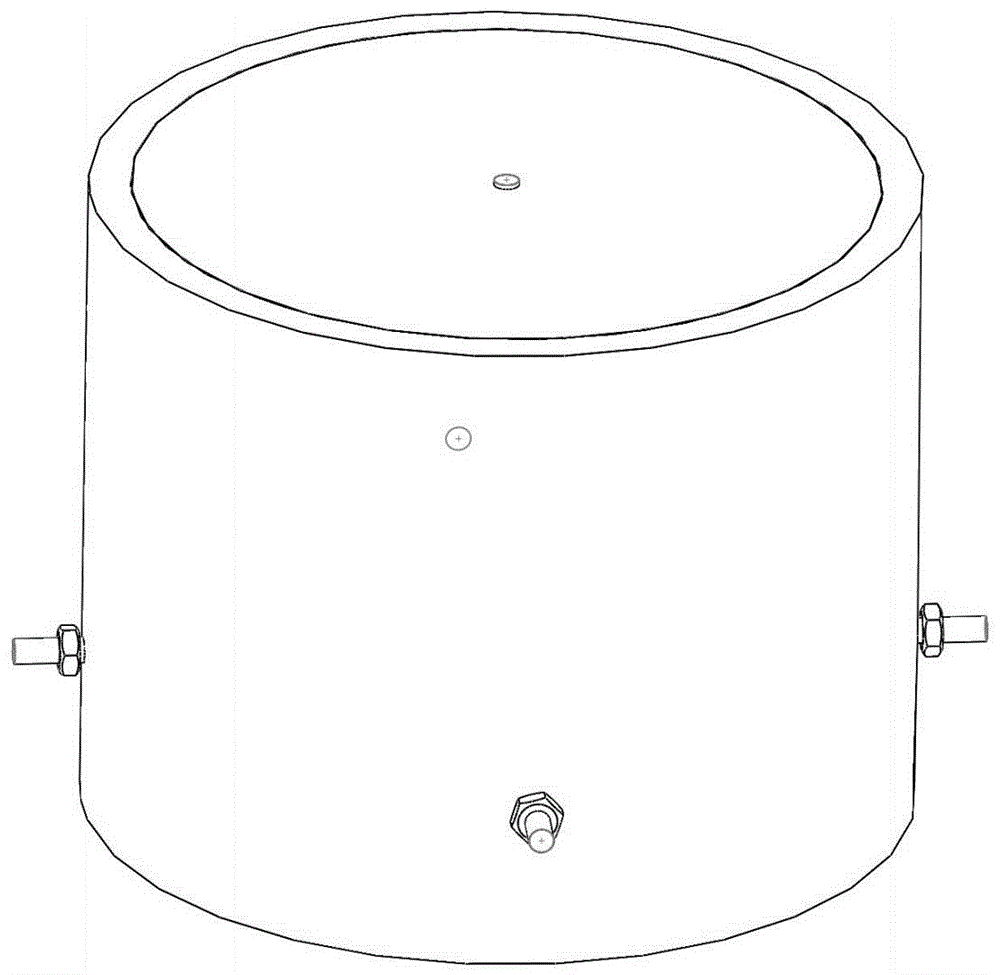

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a multi-directional response vibration energy harvester includes a support 1, a cover plate 2 is arranged above the support 1, a bottom plate 3 is provided below the support 1, and the support 1 is a cylindrical support, which is convenient for folding the piezoelectric beam 5 is set on the bracket 1. Four evenly distributed folded piezoelectric beams 5 are arranged inside the bracket 1 . The number of folded piezoelectric beams 5 is set to 4, and the folded piezoelectric beams 5 are evenly distributed along the circumference of the support 1, and the four folded piezoelectric beams 5 are on the same plane, and the plane is parallel to the cover plate 2 or the bottom plate 3, so that Each folded piezoelectric beam 5 can be received in the middle of the support 1 as uniformly as possible during operation. The two ends of the folded piezoelectric beam 5 are a fixed end and a cantilever end, the fixed end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com