A control device for a rotary table

A technology of rotary table and control device, applied in control system, motor generator control, electrical components, etc., can solve the problem of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

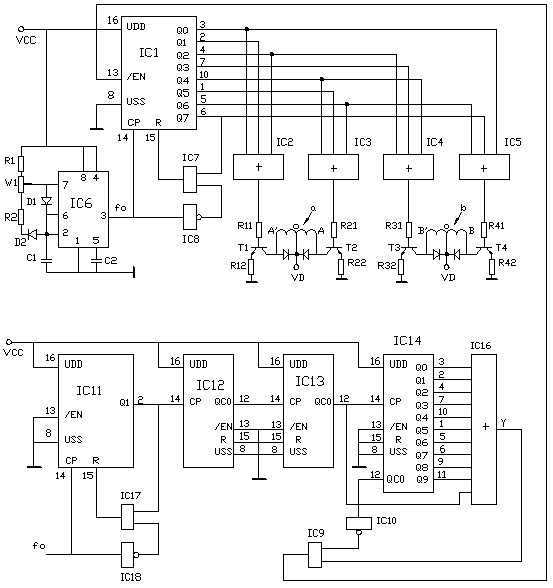

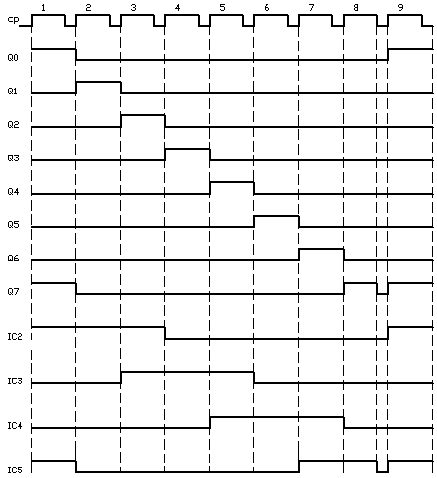

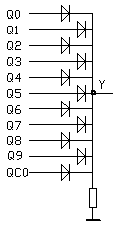

[0013] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0014] Described driving circuit is made up of counting integrated block IC1, NOT gate IC8, AND gate IC7, or gate IC2-IC5; The model of counting integrated block IC1 is CD4017, and it has 10 decoding output terminals and is pin Q0-Q9, The state of each output terminal corresponds to the number of clock pulses. At any time, only one output of Q0-Q9 is high level, and the others are low level; the pin R of the counting integrated block IC1 is the clearing terminal. When the pin R=1, the pins Q0-Q9 are all zero, the pin CP is the clock pulse input terminal, and the rising edge of the pulse triggers counting, and the pin / EN of the counting integrated block IC1 is the enable and disable terminal, and the high level prohibits Counting, low level allows counting.

[0015] The pin R of the counting integrated block IC1, the NOT gate IC8, and the AND gate IC7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com