Sintered Nd-Fe-B open type sintering feed box and use method thereof

A sintered material box, NdFeB technology, applied in inductor/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of heavy workload, inability to take into account cooling speed and tightness at the same time, low work efficiency, etc., to achieve the effect Good, improve ventilation, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

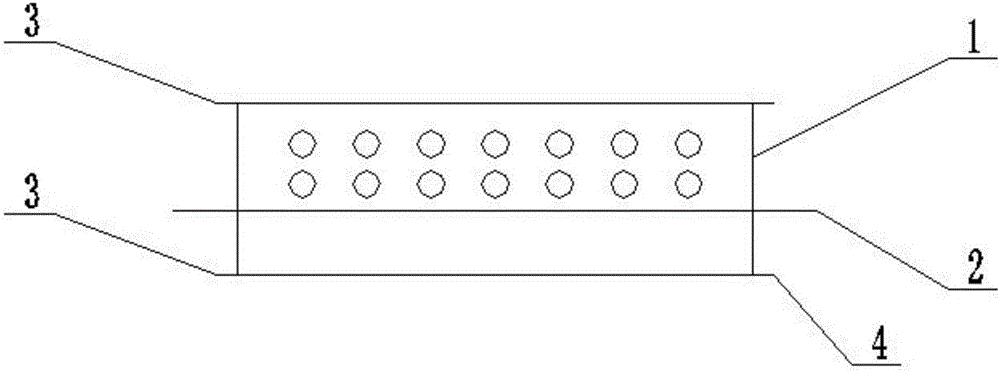

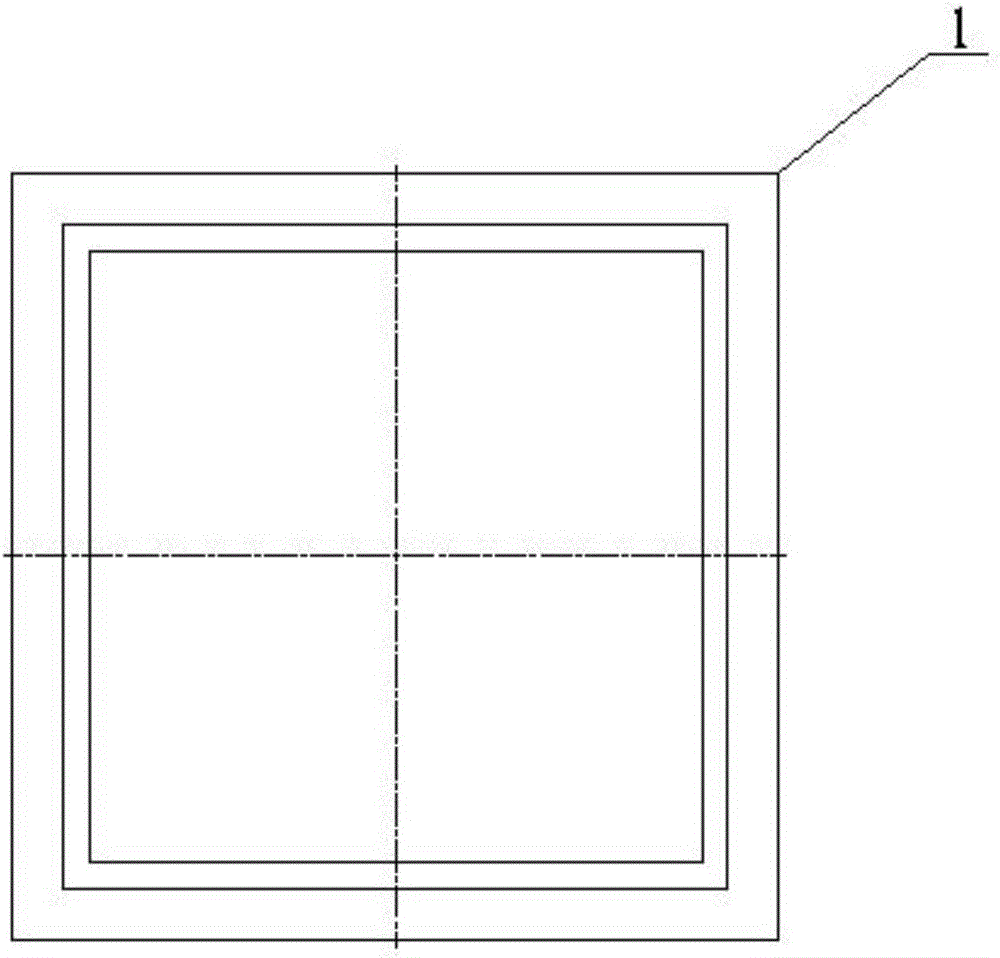

[0028] A method for using a sintered NdFeB open-type sintered material box is realized by the following steps:

[0029] Step 1: Boxing, the sintered NdFeB blank (nominal composition (PrNd) 30.8 al 0.8 Cu 0.15 Nb 0.3 B 1.0 Fe 余 ) into the above-mentioned magazine;

[0030] Step 2: Seal, use tin foil to cover the opening of the material box, and tighten the sealing edge 2 to form a complete seal as a whole;

[0031] Step 3: Opening treatment, transfer the sealed material box to a vacuum sintering furnace and heat it under vacuum. When the temperature in the vacuum sintering furnace reaches 200°C, the tin foil is melted, so that the material box is really opened, and there is a through hole on the material box 4 communicate with the outside.

[0032] Step 4: Sintering and aging. The product is sintered and aged in a vacuum sintering furnace. After the heat preservation is completed, it is filled with nitrogen or inert gas and directly quenched.

Embodiment 2

[0039] A method for using a sintered NdFeB open-type sintered material box is realized by the following steps:

[0040] Step 1: Boxing, the sintered NdFeB blank (nominal composition (PrNd) 30.8 al 0.8 Cu 0.15 Nb 0.3 B 1.0 Fe 余 ) into the above-mentioned magazine;

[0041] Step 2: Seal, use tin foil to cover the opening of the material box, and tighten the sealing edge 2 to form a complete seal as a whole;

[0042] Step 3: Opening treatment, transfer the sealed material box to the vacuum sintering furnace, and heat it under vacuum. When the temperature in the vacuum sintering furnace reaches 320°C, the tin foil will be melted, so that the material box is really opened, and there is a through hole on the material box 4 communicate with the outside.

[0043] Step 4: Sintering and aging. The product is sintered and aged in a vacuum sintering furnace. After the heat preservation is completed, it is filled with nitrogen or inert gas and directly quenched.

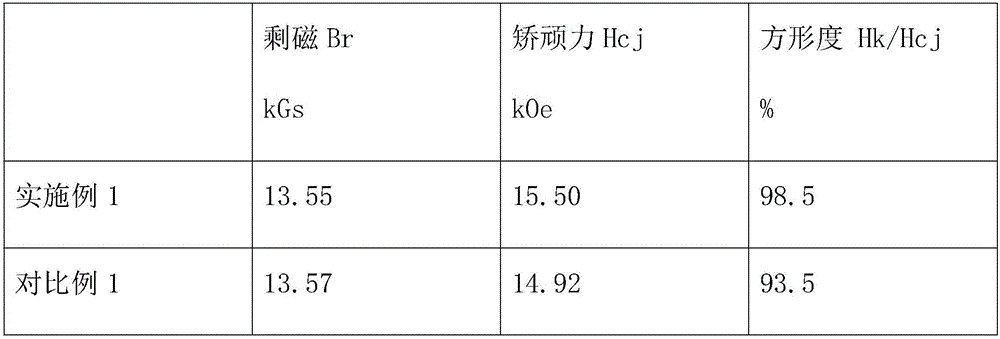

[0044] As compari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com