An integrated bearing support structure

A bearing support and bearing technology, which is applied to the rigid bracket of bearing components, bearing components, shafts and bearings, etc., can solve the problems of difficult processing of engine pipelines, burning out and preheating fuel pipes, increasing size and weight, etc. The effect of ensuring the injection angle and injection quantity, improving the lubrication reliability and reducing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the specific examples described are only intended to facilitate the understanding of the present invention, and have no limiting effect on it. It should be noted that, in the drawings or descriptions of the specification, similar or identical parts all use the same figure numbers. Implementations not shown or described in the accompanying drawings are forms known to those of ordinary skill in the art.

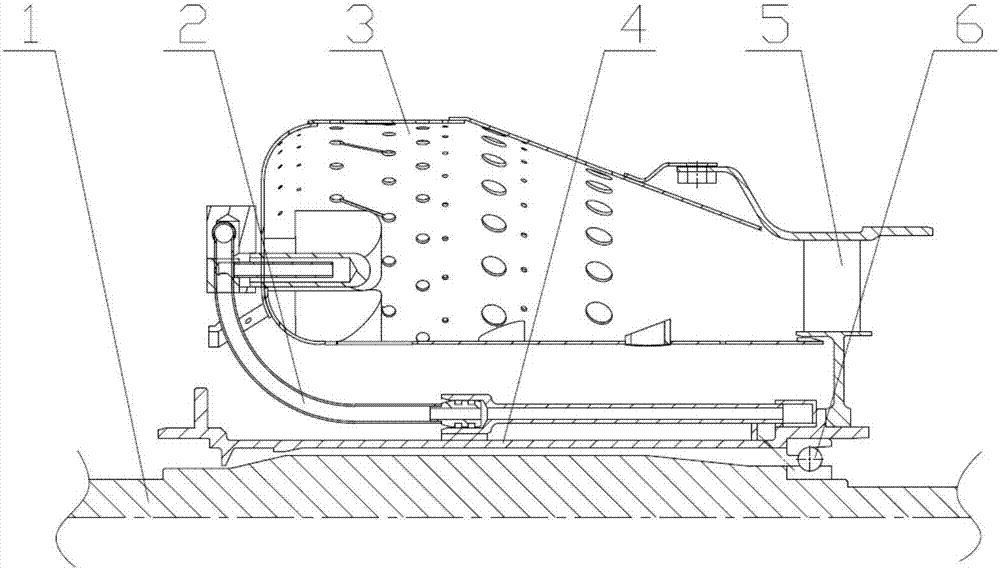

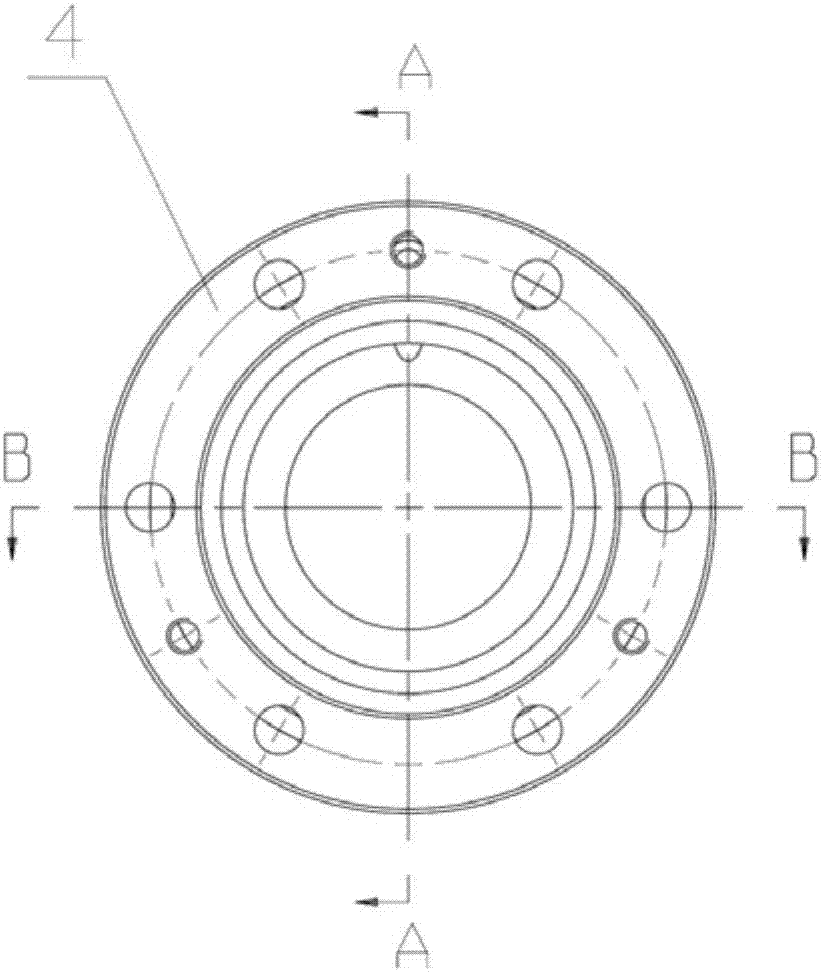

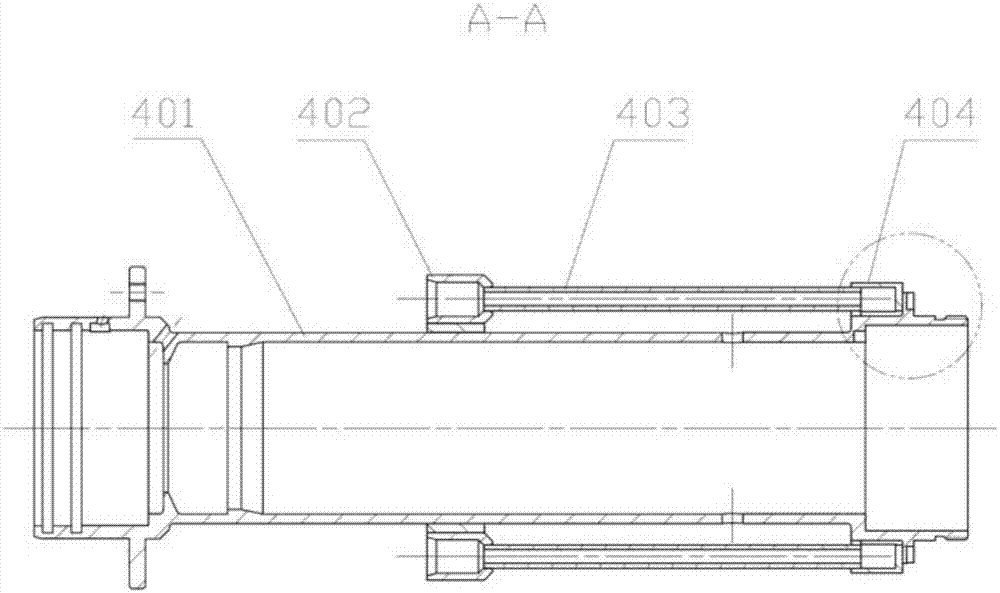

[0026] Such as figure 1 As shown, the present invention provides an integrated bearing support for a small turbojet engine. The bearing support 4 is used as an engine 0-2-0 rotor support structure, the center of which passes through the engine shaft 1, and is concentric with the bearing support 4 . The bearing 6 is installed on the inner ring of the bearing support 4, and the assembly relationship is an interference fit. The turbine guide 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com