Shell-and-tube heat exchanger suitable for three-fluid heat exchange

A shell-and-tube heat exchanger and three-fluid technology, applied in the field of heat exchange, can solve the problems of low heat exchange efficiency, difficult to manufacture core tubes, and difficult to disassemble, and achieve high heat exchange efficiency, prevent deposition, and facilitate disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

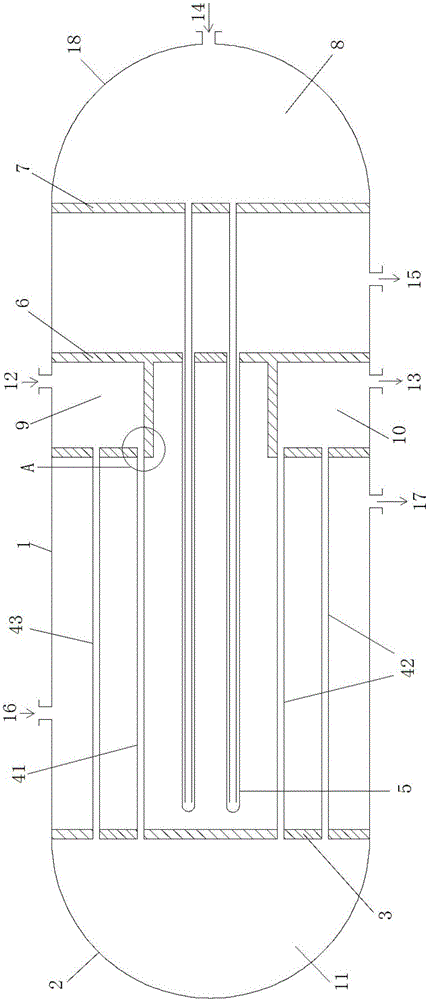

[0021] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail.

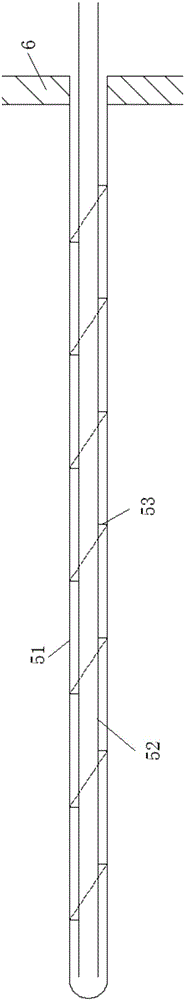

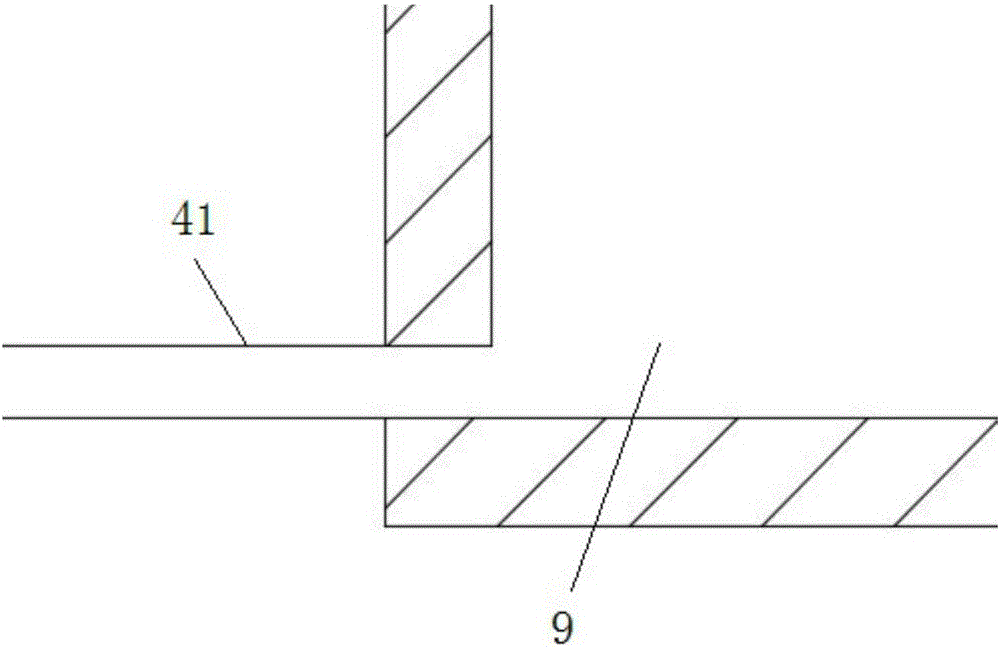

[0022] like figure 1 As shown, the shell-and-tube heat exchanger suitable for three-fluid heat exchange provided by the present invention includes: a shell 1, which forms a shell cavity inside; a first head 2, which is arranged at one end of the shell 1 , the first tube box 11 is formed inside; the second head 18 is arranged at the other end of the shell 1, and the second tube box 8 is formed inside; the first fluid heat exchange component is included in the shell 1 and is connected with the second A heat exchange tube communicated with a tube box 11, the first fluid exchanges heat by flowing in the heat exchange tube; the second fluid heat exchange assembly includes a concentric tube 5 arranged in the shell 1 and communicated with the second tube box 8 , the second fluid exchanges heat by flowing in the concentric tube 5 ; the third fluid heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com