Pressure-adjustable belt filter press

A filter press and pressure technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of inability to work, inconvenient use, inconvenient adjustment of pressure, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

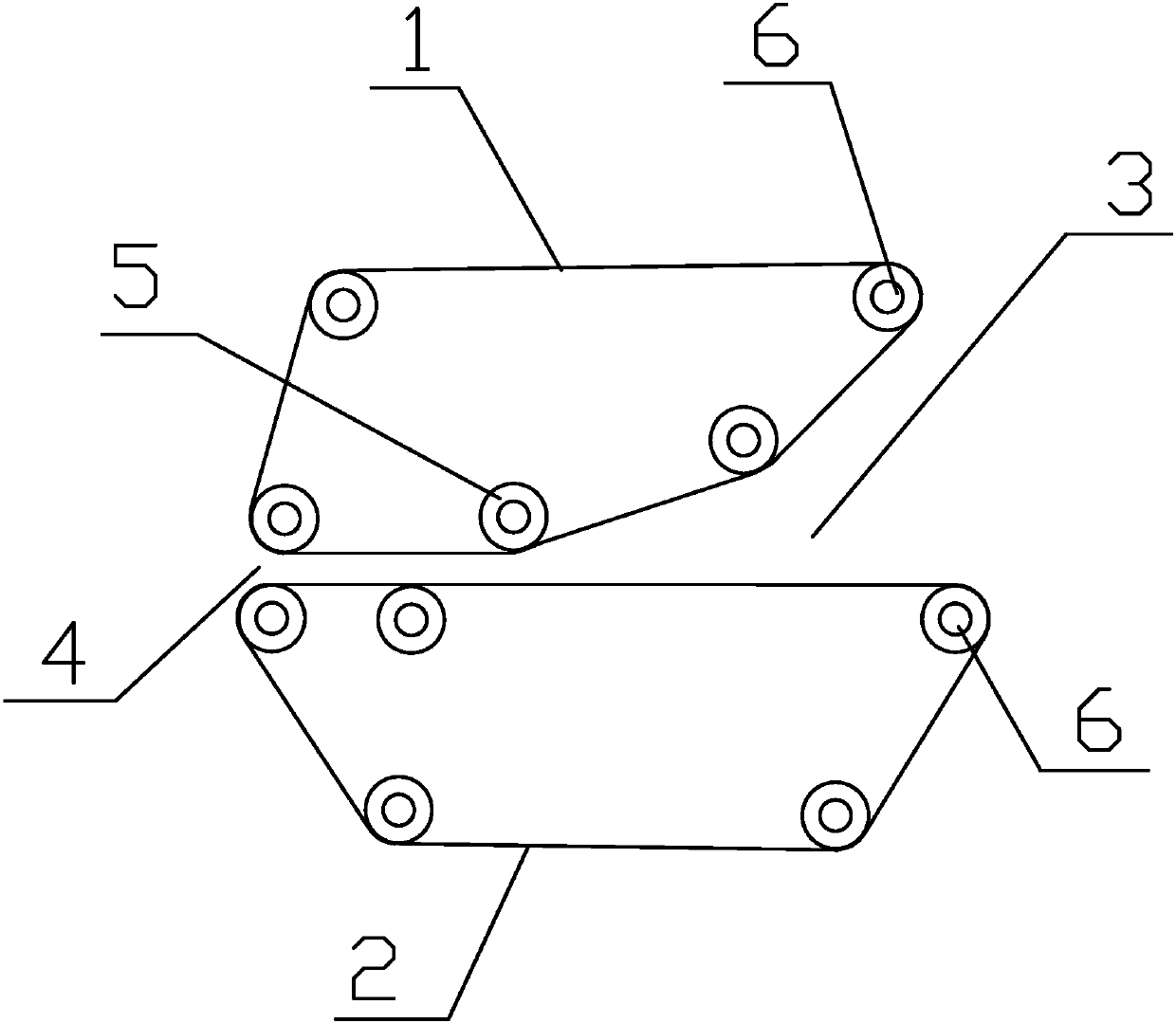

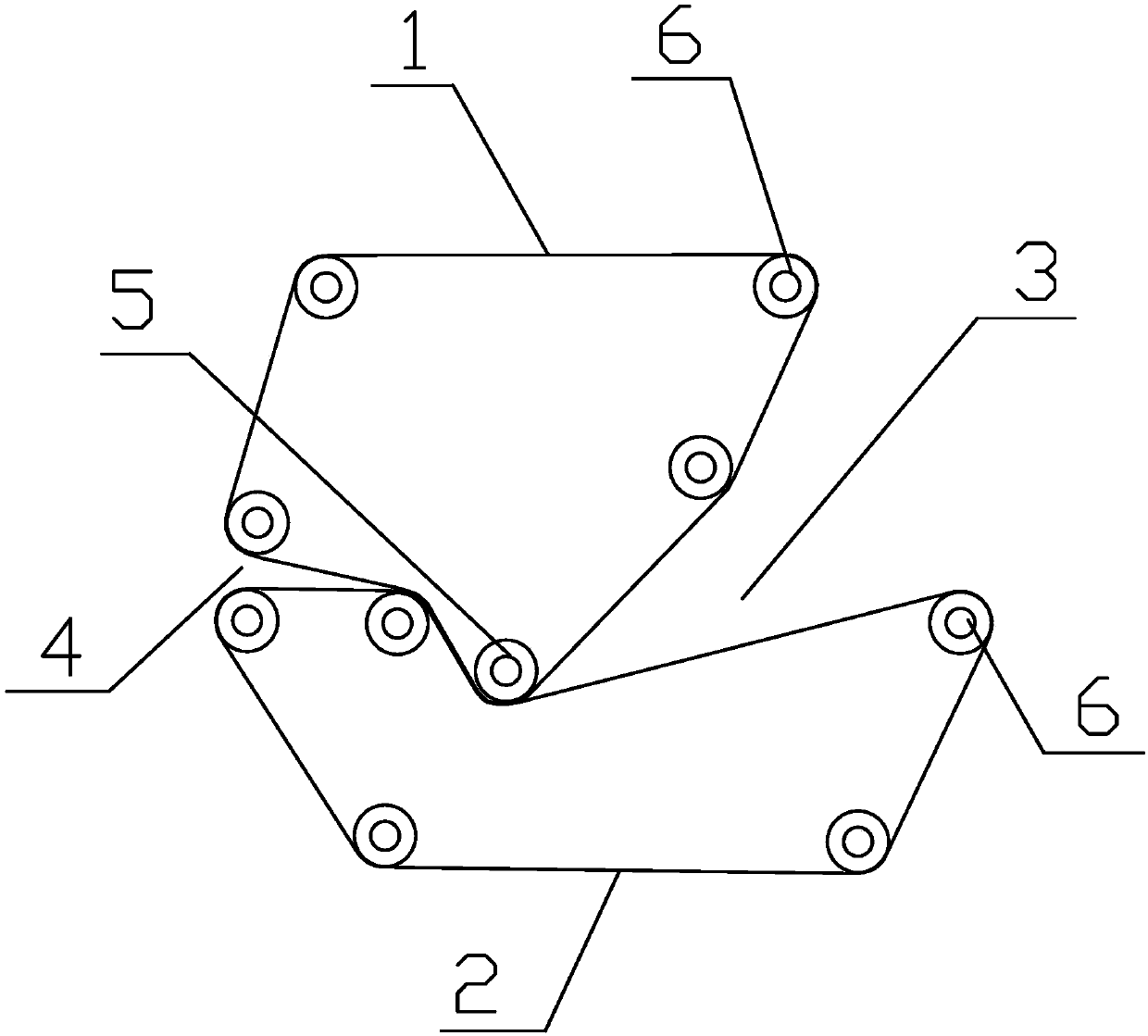

[0012] A pressure-adjustable belt filter press, comprising a frame, a drive mechanism, a filter press mechanism, a pressure adjustment mechanism, a wheelbase compensation mechanism, a filter belt deviation correction mechanism and a filter belt backwashing mechanism, and the filter press mechanism consists of The upper filter belt circle and the lower filter belt circle formed by multiple rollers, a material inlet 3 and a material outlet 4 are formed between the upper filter belt circle and the lower filter belt circle, and the upper filter belt circle is sleeved with an upper filter belt 1. A lower filter belt 2 is sheathed outside the lower filter belt ring. The pressure adjustment mechanism includes a floating roller 5, a bearing seat, a slider, and a hydraulic cylinder. The floating roller 5 presses on the inner side of the upper filter belt 1.

[0013] The wheelbase compensation mechanism includes a compensation roller 6, a bearing seat, a slider and a cylinder, and the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap