A kind of preparation method of nonionic surfactant adsorption material

A non-ionic surface, adsorption material technology, applied in the field of preparation of waste water treatment materials, can solve the problems of the need to improve adsorption efficiency, low adsorption capacity, etc., and achieve the effects of low cost, high adsorption efficiency and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step (1) swelling

[0024] Add 100Kg of dichloroethane and 15Kg of styrene-based macroporous adsorbent SD200 into a 500L reactor, stir at 25°C for 3h, and filter out the dichloroethane.

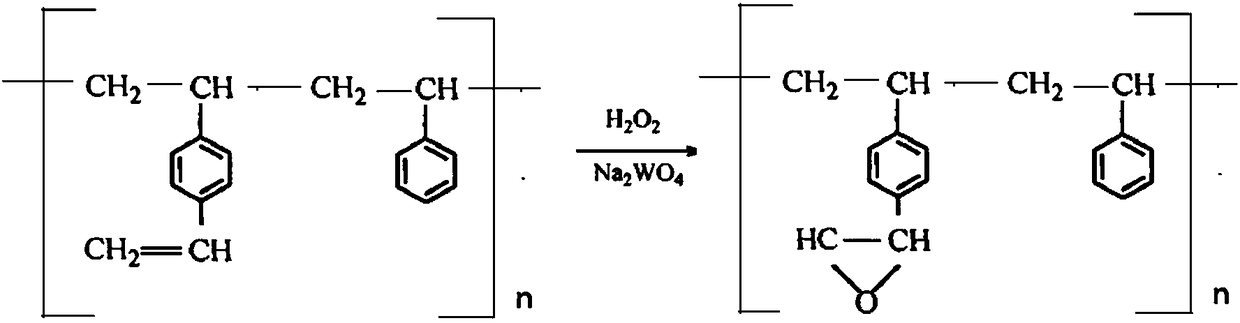

[0025] Step (2) epoxidation reaction

[0026] In the reaction kettle of step (1), add 70Kg of deionized water and 2Kg of sodium tungstate to the material after filtering dichloroethane, and dropwise add 30Kg of hydrogen peroxide with a mass percentage concentration of 30% for reaction, and the reaction temperature is 60°C , the reaction time is 4h, after the reaction is completed, the product is obtained by filtering and drying. The resulting product number is JH-1.

Embodiment 2

[0028] Step (1) swelling

[0029] Add 100Kg of dichloroethane and 10Kg of styrene-based macroporous adsorbent SD300 into a 500L reactor, stir at 25°C for 2h, and filter out the dichloroethane.

[0030] Step (2) epoxidation reaction

[0031] In the reaction kettle of step (1), add 50Kg deionized water, 0.5Kg sodium tungstate to the material after filtering dichloroethane, drip the hydrogen peroxide 20Kg that mass percent concentration is 30% to react, and reaction temperature is 50 ℃, the reaction time is 6h, after the reaction is completed, the product is obtained by filtering and drying. The resulting product number is JH-2.

Embodiment 3

[0033] Step (1) swelling

[0034] Add 100Kg of dichloroethane and 20Kg of styrene-based macroporous adsorbent SD600 into a 500L reactor, stir at 25°C for 6h, and filter out the dichloroethane.

[0035] Step (2) epoxidation reaction

[0036] In the reactor of step (1), add 100Kg of deionized water and 5Kg of sodium tungstate to the material after filtering dichloroethane, and dropwise add 40Kg of hydrogen peroxide with a mass percentage concentration of 30% for reaction, and the reaction temperature is 70°C , the reaction time is 2h, after the reaction is completed, filter and dry to obtain the product. The resulting product number is JH-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com