Ore grinding technology production method using hard rocks as ore grinding medium

A grinding medium and production method technology, applied in grain processing, etc., can solve problems such as unstable medium filling rate, achieve the effect of reducing pollution and impact, and improving indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

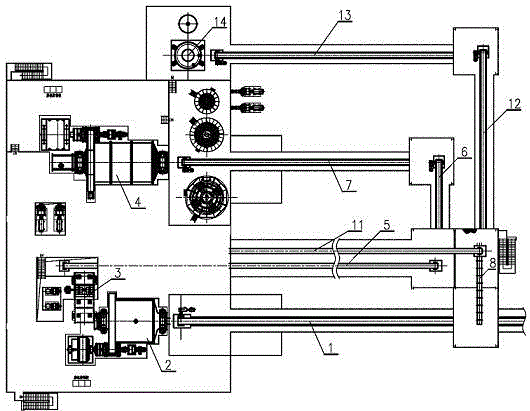

[0014] Embodiment 1: as figure 1 As shown, a kind of ore grinding process production method adopts pebbles as the grinding medium, the autogenous / semi-autogenous mill 2 and the ball mill 4 are arranged in parallel, and the vertical re-mill 14 is arranged on the ore grinding bridge, and placed with the ball mill 4 feed side. The raw ore is fed into the autogenous / semi-autogenous mill 2 by the feeding belt conveyor 1 of the autogenous / semi-autogenous mill, and the discharge of the autogenous / semi-autogenous mill 2 is screened and classified by the double-layer linear vibrating screen 3, and then classified Two grades of +30mm and -30~+8mm rocks are produced, and the +30mm rocks enter the rock storage bin through one of the +30mm rock belt conveyors 5 and +30mm rock high-inclination belt conveyor 6. There is a quantitative metering feeding belt machine under the warehouse, and the stubborn stone is fed into the ball mill 4 through the second 7 of the +30mm stubborn stone belt co...

Embodiment 2

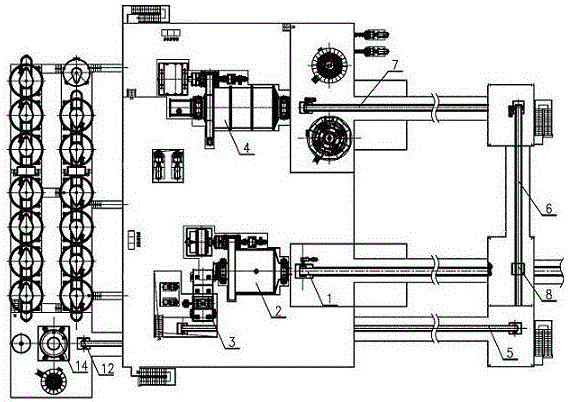

[0015] Embodiment 2: as figure 2 As shown, a kind of grinding process production method that adopts cob as the grinding medium, autogenous / semi-autogenous mill 2 and ball mill 4 are arranged in parallel, and re-mill 14 is arranged in the flotation bridge, placed in autogenous / semi-autogenous mill 4 SAG mill 2 sides. The raw ore is fed into the autogenous / semi-autogenous mill 2 by the feeding belt conveyor 1 of the autogenous / semi-autogenous mill, and the discharge of the autogenous / semi-autogenous mill 2 is screened and classified by the double-layer linear vibrating screen 3, and then classified Two grades of +30mm and -30~+8mm rocks are produced, and the +30mm rocks enter the rock storage bin through one of the +30mm rock belt conveyors 5 and +30mm rock high-inclination belt conveyor 6. There is a quantitative metering feeding belt machine under the warehouse, and the stubborn stone is fed into the ball mill 4 through the second 7 of the +30mm stubborn stone belt conveyor ...

Embodiment 3

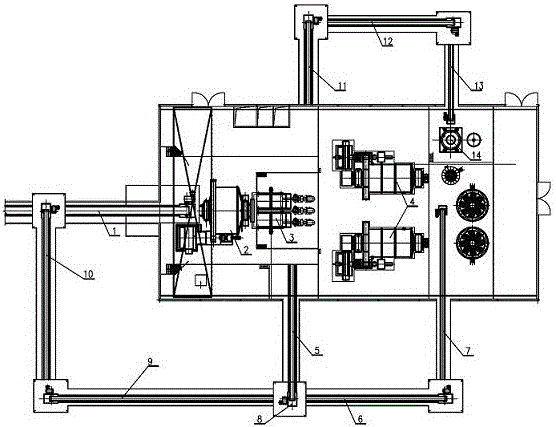

[0016] Embodiment 3: as image 3 As shown, a kind of ore grinding process production method that adopts pebbles as the grinding medium, the autogenous / semi-autogenous mill 2 and the ball mill 4 adopt the arrangement of discharge relative to one line, and the re-mill 14 is arranged at the feeding end of the ball mill. side. The raw ore is fed into the autogenous / semi-autogenous mill 2 by the feeding belt conveyor 1 of the autogenous / semi-autogenous mill, and the discharge of the autogenous / semi-autogenous mill 2 is screened and classified by the double-layer linear vibrating screen 3, and then classified Two grades of +30mm and -30~+8mm rocks are produced, and the +30mm rocks enter the rock storage bin through one of the +30mm rock belt conveyors 5 and +30mm rock high-inclination belt conveyor 6. There is a quantitative metering feeding belt machine under the warehouse, and the stubborn stone is fed into the ball mill 4 through the second 7 of the +30mm stubborn stone belt con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com