Plastic cleaning device

A technology for plastic cleaning and washing liquid, applied in the field of plastic manufacturing, can solve problems such as poor washing liquid effect and washing liquid waste, and achieve the effects of saving washing liquid, good ability to carry dirt, and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

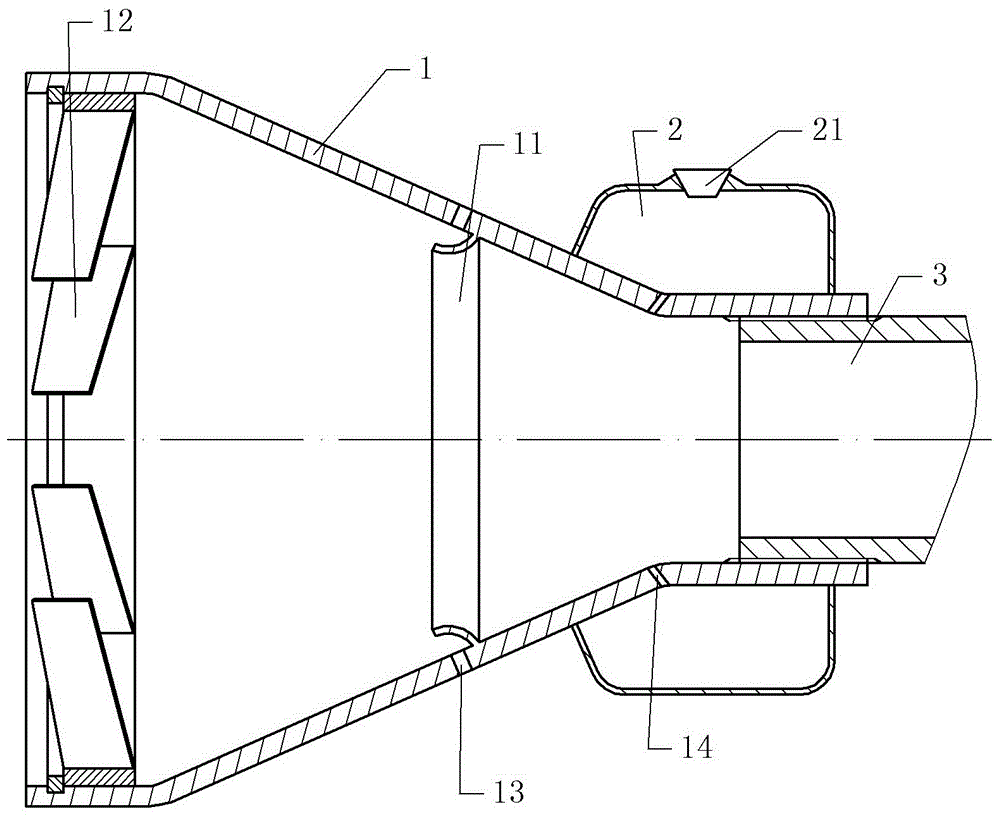

[0015] The reference numerals in the drawings of the description include: shroud 1 , washing liquid chamber 2 , high-pressure water pipe 3 , annular baffle 11 , impeller 12 , air inlet 13 , washing liquid inlet 14 , and plug 21 .

[0016] The embodiment is basically as figure 1 Shown:

[0017] The plastic cleaning device of this embodiment includes a cone-shaped diversion cover 1; the small end of the diversion cover 1 is a connection part that cooperates with the high-pressure water pipe 3, and the large end of the diversion cover 1 is a liquid outlet. The small end of the shroud 1 is provided with a washing liquid chamber 2, and the side wall of the small end of the shroud 1 is provided with five washing liquid inlets 14, and the washing liquid chamber 2 is provided with an inlet for loading the washing liquid. Feed mouth, feed inlet place is provided with plugging 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com