Panel painting device with drying function

A sheet and function technology, applied in the field of sheet painting devices with drying function, can solve the problems of affecting efficiency, uneven painting, and lowering the qualified rate of finished products, and achieve the effects of convenient operation, accurate painting, and avoidance of flow paint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

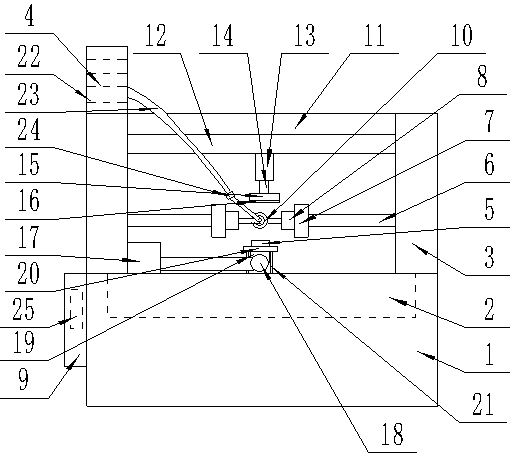

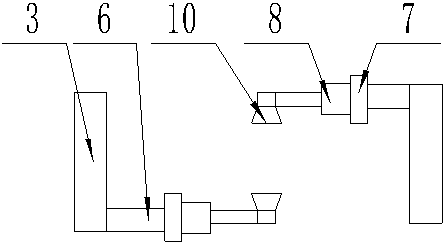

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a plate painting device with drying function includes a frame body 1, a lifting unit is arranged on the frame body 1, a liquid receiving tank 2 is arranged below the lifting unit, and a side of the frame body 1 A pair of adjusting bolt frames 3 are arranged on the wall, a paint box 4 is arranged on one of the adjusting bolt frames 3, a pair of spraying units are arranged on the adjusting bolt frame 3, reciprocating A movement unit, the reciprocating movement unit is provided with a dryer 5, and the frame 1 is provided with a pair of limit units for limiting the movement of the dryer 5, and the spraying unit is respectively arranged on a pair of adjustment units. The support arm 6 on the bolt frame 3, the fixed seat 7 arranged on the support arm 6, the linear motor 8 arranged on the fixed seat 7 and the multiple nozzles which are arranged on the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com