Precise continued printing method and apparatus used under abnormal 3D printing condition, and equipment

A 3D printing, abnormal state technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve problems such as data loss, inability to determine when the command execution ends, and inability to achieve accurate continuous printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

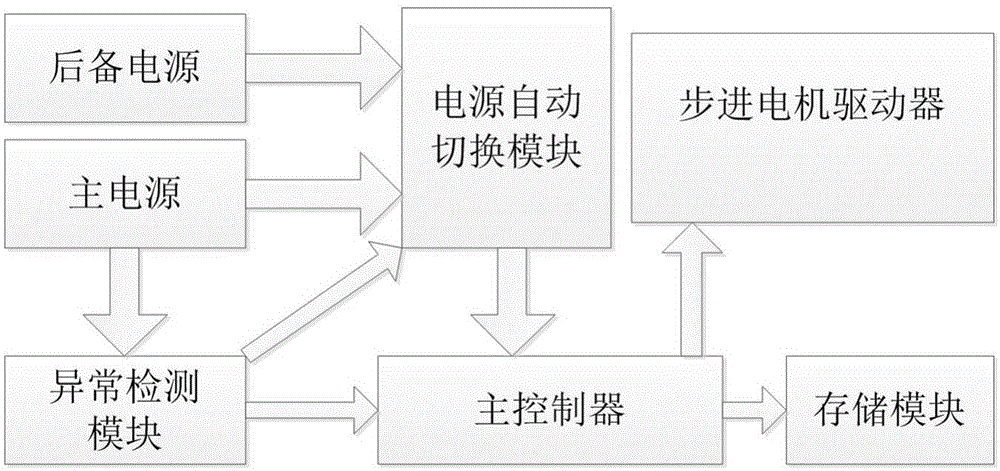

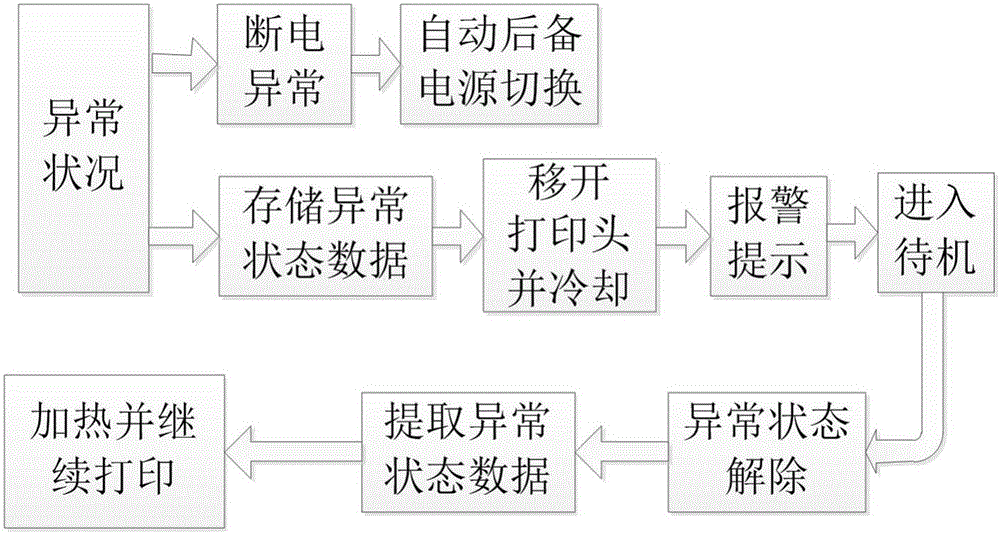

[0022] The purpose of the present invention is to provide a precise continuous printing method for abnormal power failure handling in the event of a power outage during the 3D printing process, so as to improve the stability of 3D printing. In order to achieve the above purpose, the present invention provides a 3D printer, including a precise follow-up device, as attached figure 1 As shown, the device includes a backup power supply, an automatic power switch module, an abnormality detection module, a main controller, a storage module and a stepping motor driver. The automatic switching module of the power supply is respectively connected with the backup power supply, the main power supply and the main controller; the abnormal detection module is used to detect abnormal conditions and send abnormal signals to the main controller. Also send a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com