A propeller that reduces stress at the blade root and reduces tip vortices

A propeller and stress technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve the problems that the blade pressure cannot be fully exerted, the cavitation performance of the propeller is deteriorated, and the thrust at the blade root is reduced, achieving high thrust and reducing Cavitation, the effect of reducing tip vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

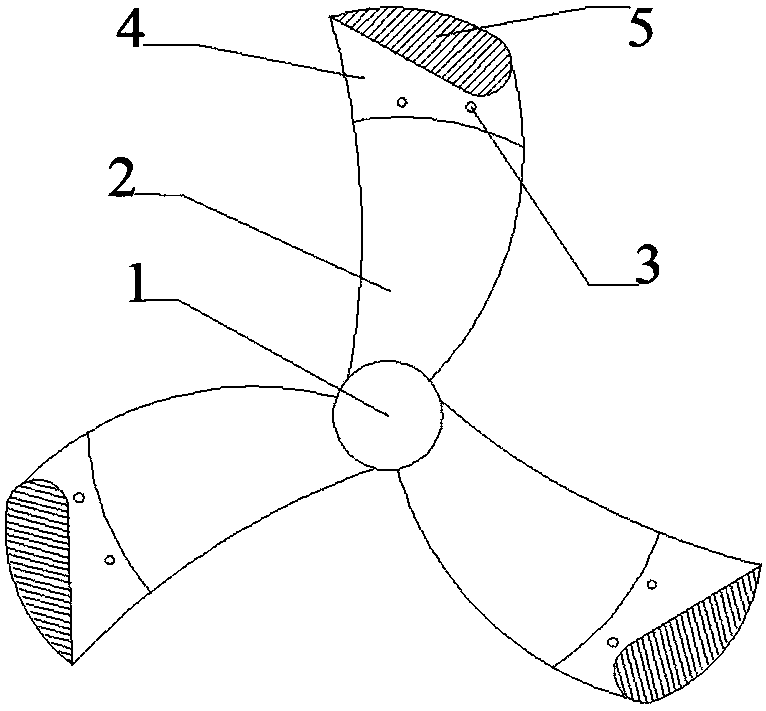

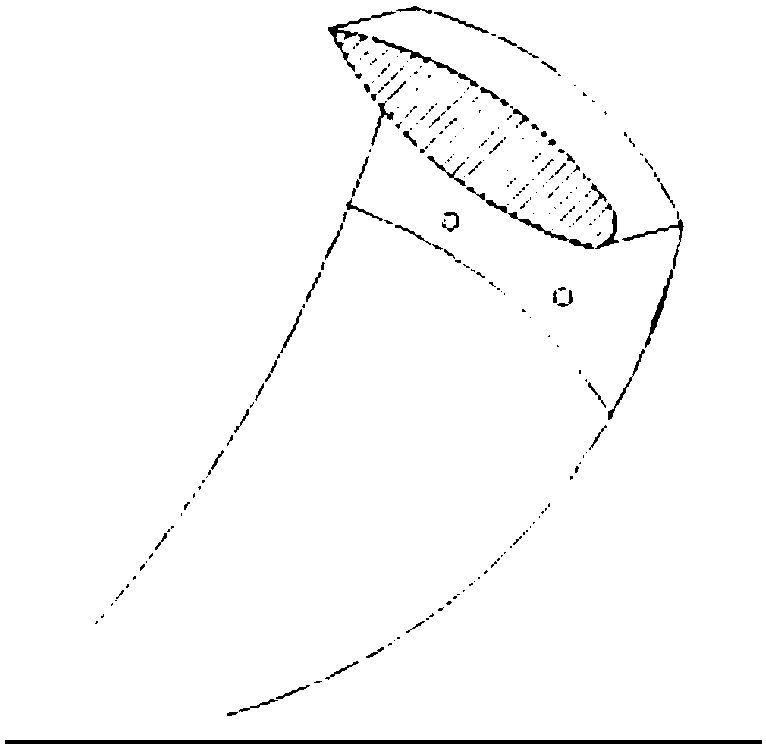

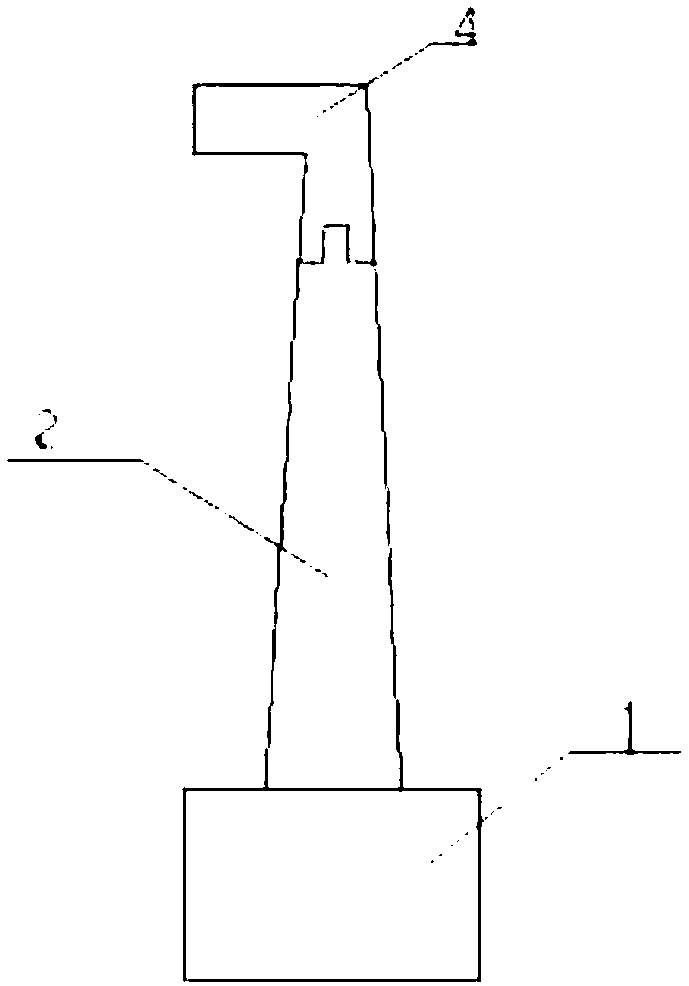

[0016] to combine Figure 1~3 , the present invention is a propeller that reduces the stress at the blade root and reduces the tip vortex, which includes a hub 1, a blade 2, a screw 3, a blade tip leaflet 4 and a transverse flow stop plate 5, the blade tip leaflet 4 and the blade 2 Use mosaic connection and fix it with screw 3.

[0017] See figure 1 , the transverse flow stop plate 5 is fixed on the blade tip leaflet 4, the blade tip leaflet 4 and the transverse flow stop plate 5 are of an integrated structure, the transverse flow stop plate 5 is perpendicular to the blade tip leaflet 4, and the cut surface shape of the transverse flow stop plate 5 is The airfoil is inverted so that when the propeller rotates in the water, it will generate a force directed to the hub, offset the centrifugal force generated by a part of the blades, and reduce the strength require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com