Workpiece lifting and temporary storing device for production line

A technology for production lines and workpieces is applied in the field of workpiece buffering devices and workpiece lifting buffering devices in production lines to achieve the effects of reducing process costs, reducing failure rates, and improving automation and productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

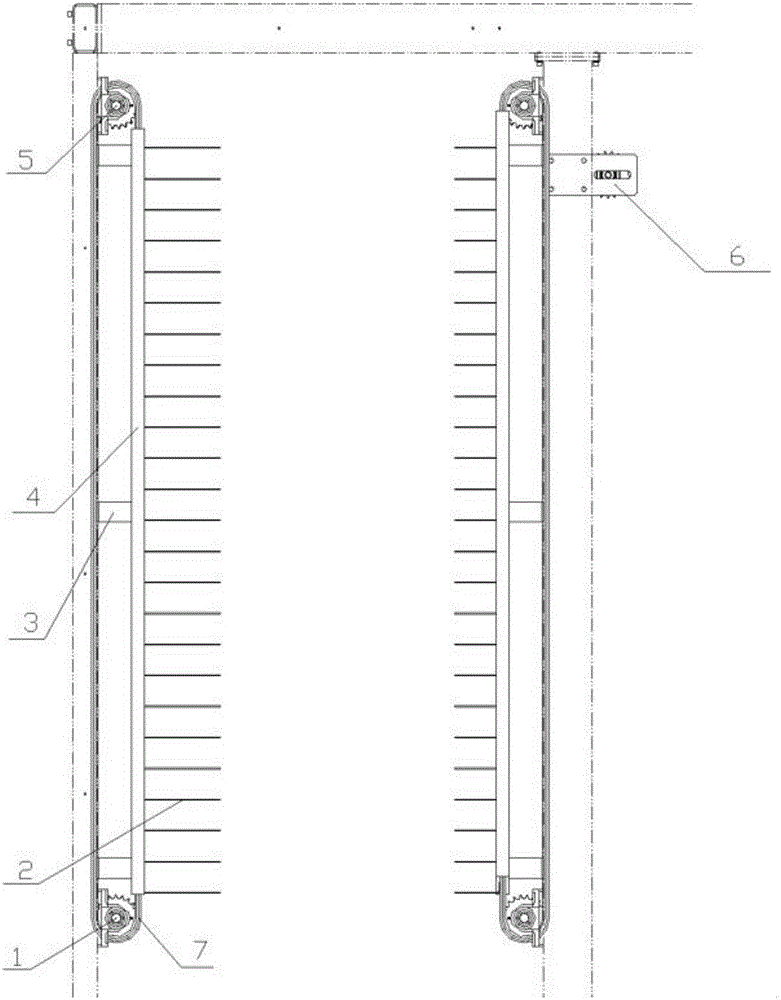

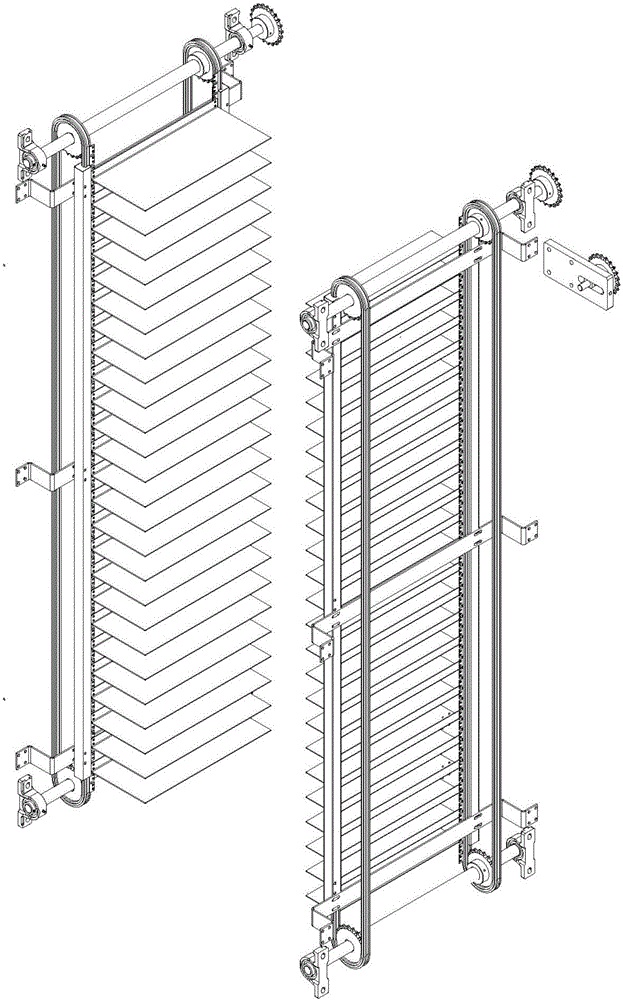

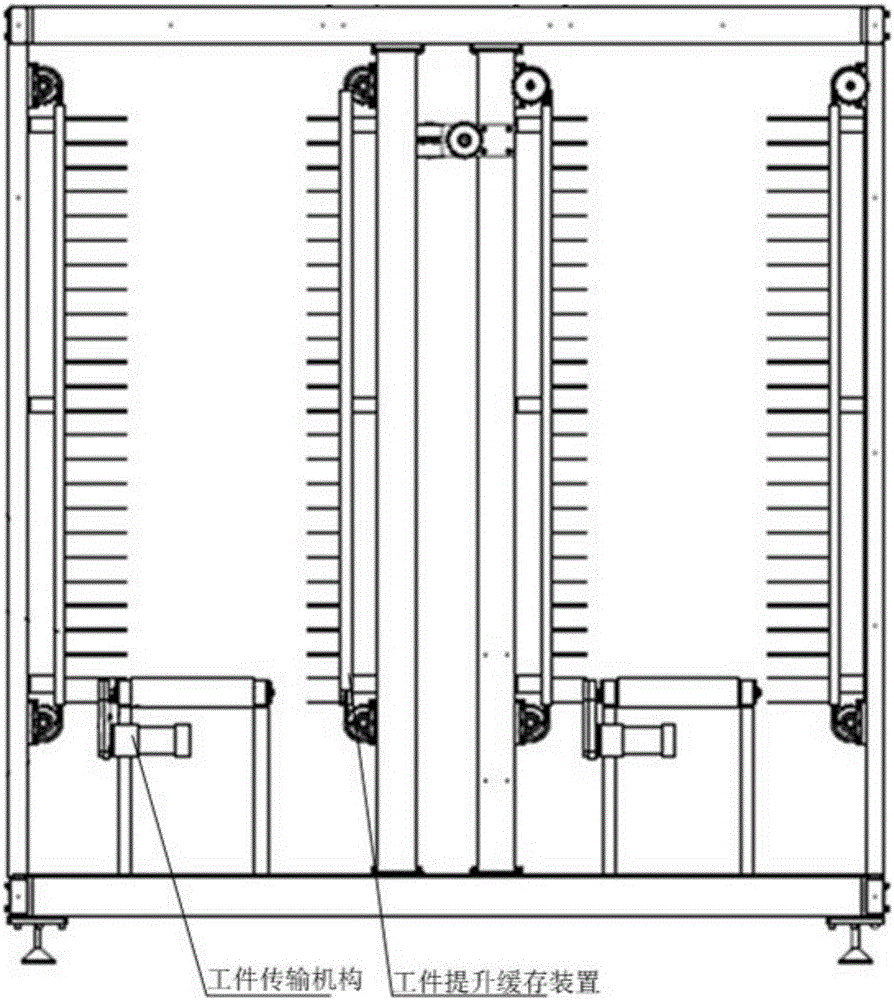

[0015] Such as figure 1 and 2 As shown, the workpiece lifting buffer device of the present invention is mainly used for workpiece turnover in the production line, and it includes two lifting mechanisms installed on the frame. The lifting mechanism includes a driven shaft 1, a driving shaft 5 and a chain 7, and the driving shaft 5 and the driven shaft 1 are installed on the frame, the driving shaft 5 and the driven shaft 1 are arranged in an up and down structure, the driven shaft 1 is located below the driving shaft 5, and the driving shaft 5 and the driven shaft 1 are respectively provided with two The gear meshed with the chain 7; the chain 7 is two pieces, arranged in a vertical ring shape, respectively set on the two gears of the driving shaft 5 and the driven shaft 1, the driving shaft 5 is connected to the driving motor, and the driving motor passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com