Combined sewage purification treatment process and use method

A sewage purification and treatment process technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor sedimentation, long sedimentation time, and incomplete separation of mud and water. , to achieve good sedimentation, good mud-water separation, good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

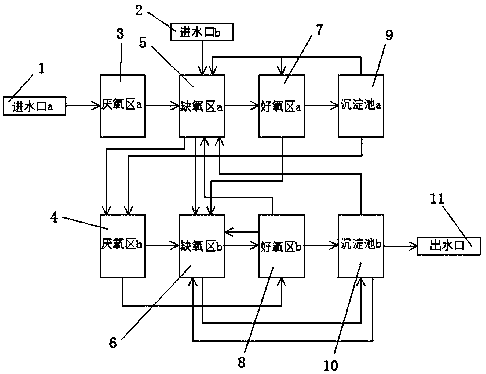

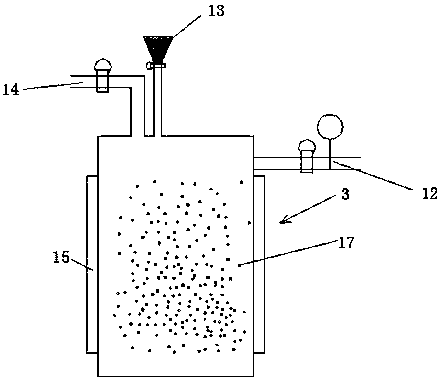

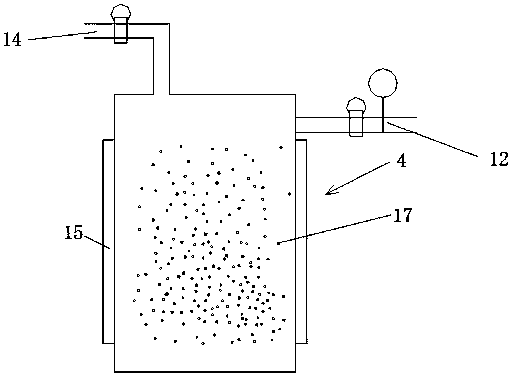

Embodiment 1

[0034] see Figure 1-7 , the present invention provides a technical solution: a combined sewage purification treatment process, including water inlet a1, water inlet b2, anaerobic zone a3, anaerobic zone b4, anoxic zone a5, anoxic zone b6, aerobic zone a7, aerobic zone b8, sedimentation tank a9, sedimentation tank b10 and water outlet 11; anaerobic zone a3 includes outlet pipe 12, container 13, water inlet pipe 14 and magnetic field generator 15; anaerobic zone b4 includes outlet pipe 12, inlet Water pipe 14 and magnetic field generator 15; Anoxic zone a5 comprises water outlet pipe 12, container 13, water inlet pipe 14, aeration device 16 and magnetic field generator 15; Anoxic zone b6, aerobic zone a7 and aerobic zone b8 comprise outlet Water pipe 12, water inlet pipe 14, aeration device 16 and magnetic field generator 15; sedimentation tank a9 and sedimentation tank b10 include water outlet pipe 12, water inlet pipe 14 and collection device 20;

[0035] The container 13 is...

Embodiment 2

[0048] see Figure 1-7 , the present invention provides a technical solution: a combined sewage purification treatment process, including water inlet a1, water inlet b2, anaerobic zone a3, anaerobic zone b4, anoxic zone a5, anoxic zone b6, aerobic zone a7, aerobic zone b8, sedimentation tank a9, sedimentation tank b10 and water outlet 11; anaerobic zone a3 includes outlet pipe 12, container 13, water inlet pipe 14 and magnetic field generator 15; anaerobic zone b4 includes outlet pipe 12, inlet Water pipe 14 and magnetic field generator 15; Anoxic zone a5 comprises water outlet pipe 12, container 13, water inlet pipe 14, aeration device 16 and magnetic field generator 15; Anoxic zone b6, aerobic zone a7 and aerobic zone b8 comprise outlet Water pipe 12, water inlet pipe 14, aeration device 16 and magnetic field generator 15; sedimentation tank a9 and sedimentation tank b10 include water outlet pipe 12, water inlet pipe 14 and collection device 20;

[0049] The container 13 is...

Embodiment 3

[0062] see Figure 1-7 , the present invention provides a technical solution: a combined sewage purification treatment process, including water inlet a1, water inlet b2, anaerobic zone a3, anaerobic zone b4, anoxic zone a5, anoxic zone b6, aerobic zone a7, aerobic zone b8, sedimentation tank a9, sedimentation tank b10 and water outlet 11; anaerobic zone a3 includes outlet pipe 12, container 13, water inlet pipe 14 and magnetic field generator 15; anaerobic zone b4 includes outlet pipe 12, inlet Water pipe 14 and magnetic field generator 15; Anoxic zone a5 comprises water outlet pipe 12, container 13, water inlet pipe 14, aeration device 16 and magnetic field generator 15; Anoxic zone b6, aerobic zone a7 and aerobic zone b8 comprise outlet Water pipe 12, water inlet pipe 14, aeration device 16 and magnetic field generator 15; sedimentation tank a9 and sedimentation tank b10 include water outlet pipe 12, water inlet pipe 14 and collection device 20;

[0063] The container 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com