Integrated sewage treatment system and application method thereof

A sewage treatment system and sewage technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor settling, long settling time, and incomplete separation of mud and water , to achieve the effects of good sedimentation, good mud-water separation, and good water purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

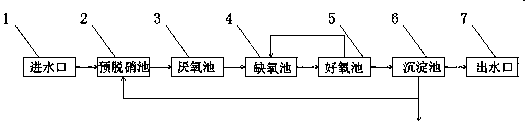

[0031] see Figure 1-7 , the present invention provides a technical solution: an integrated sewage treatment system, including a water inlet 1, a pre-denitration tank 2, an anaerobic tank 3, anoxic tank 4, an aerobic tank 5, a sedimentation tank 6 and a water outlet 7; The sewage enters from the water inlet 1, passes through the pre-denitrification tank 2, the anaerobic tank 3, the anoxic tank 4, the aerobic tank 5, and the sedimentation tank 6 in sequence, and finally discharges from the water outlet 7, and the mixed solution in the aerobic tank 5 can flow back To the anoxic tank 4, a part of the immobilized microbial balls 17 in the sedimentation tank 6 is returned to the pre-denitrification tank 2, and the other part is discharged;

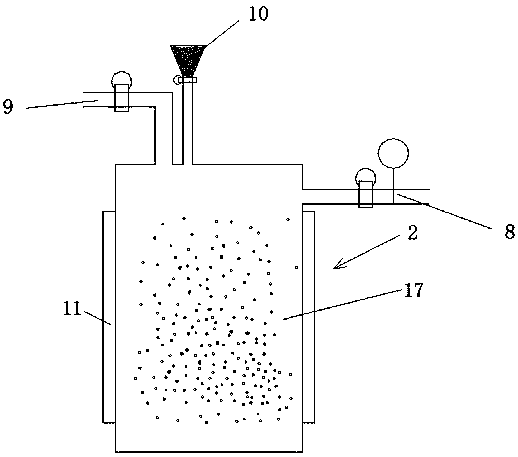

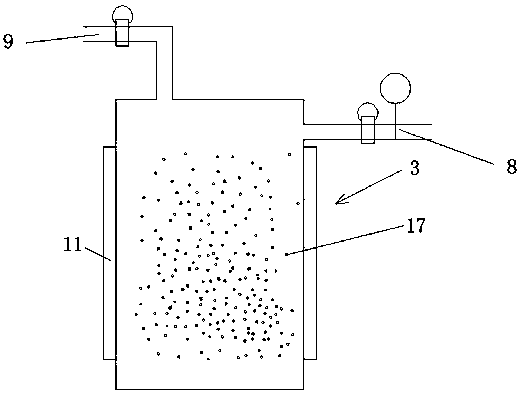

[0032] The pre-denitration pool 2 includes an outlet pipe 8, an inlet pipe 9, a container 10 and a magnetic field generator 11; the anaerobic pool 3 includes an outlet pipe 8, an inlet pipe 9 and a magnetic field generator 11; the anoxic pool 4...

Embodiment 2

[0042] see Figure 1-7 , the present invention provides a technical solution: an integrated sewage treatment system, including a water inlet 1, a pre-denitration tank 2, an anaerobic tank 3, anoxic tank 4, an aerobic tank 5, a sedimentation tank 6 and a water outlet 7; The sewage enters from the water inlet 1, passes through the pre-denitrification tank 2, the anaerobic tank 3, the anoxic tank 4, the aerobic tank 5, and the sedimentation tank 6 in sequence, and finally discharges from the water outlet 7, and the mixed solution in the aerobic tank 5 can flow back To the anoxic tank 4, a part of the immobilized microbial balls 17 in the sedimentation tank 6 is returned to the pre-denitrification tank 2, and the other part is discharged;

[0043] The pre-denitration pool 2 includes an outlet pipe 8, an inlet pipe 9, a container 10 and a magnetic field generator 11; the anaerobic pool 3 includes an outlet pipe 8, an inlet pipe 9 and a magnetic field generator 11; the anoxic pool 4...

Embodiment 3

[0053] see Figure 1-7 , the present invention provides a technical solution: an integrated sewage treatment system, including a water inlet 1, a pre-denitration tank 2, an anaerobic tank 3, anoxic tank 4, an aerobic tank 5, a sedimentation tank 6 and a water outlet 7; The sewage enters from the water inlet 1, passes through the pre-denitrification tank 2, the anaerobic tank 3, the anoxic tank 4, the aerobic tank 5, and the sedimentation tank 6 in sequence, and finally discharges from the water outlet 7, and the mixed solution in the aerobic tank 5 can flow back To the anoxic tank 4, a part of the immobilized microbial balls 17 in the sedimentation tank 6 is returned to the pre-denitrification tank 2, and the other part is discharged;

[0054] The pre-denitration pool 2 includes an outlet pipe 8, an inlet pipe 9, a container 10 and a magnetic field generator 11; the anaerobic pool 3 includes an outlet pipe 8, an inlet pipe 9 and a magnetic field generator 11; the anoxic pool 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com