A kind of zirconium boride plasma spraying raw material and preparation method thereof

A zirconium boride and plasma technology is applied in the field of high temperature resistant stealth materials, which can solve the problems of high oxide impurity content, high impurity content and low density of zirconium boride materials, and achieves low production cost, high density and granularity. Size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

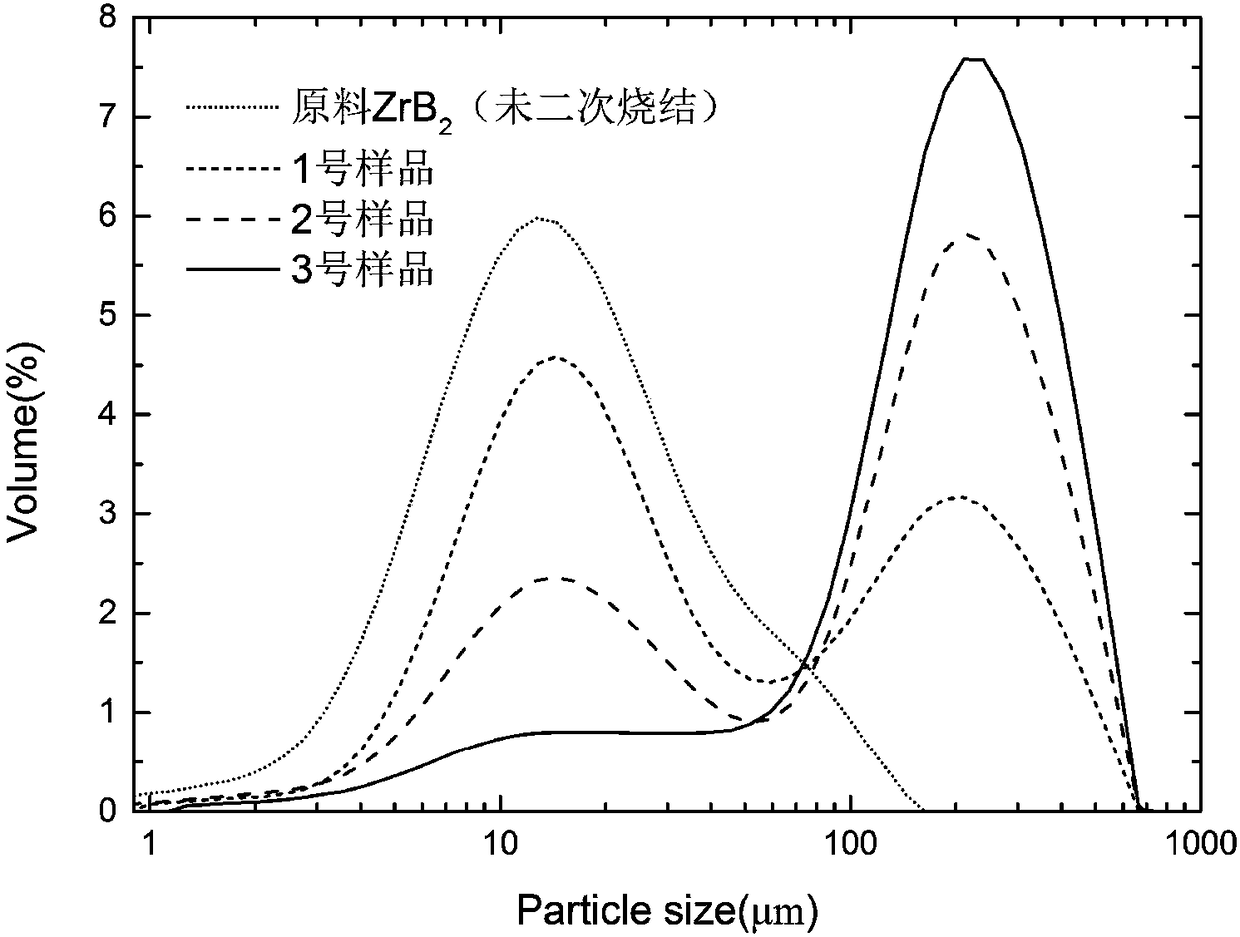

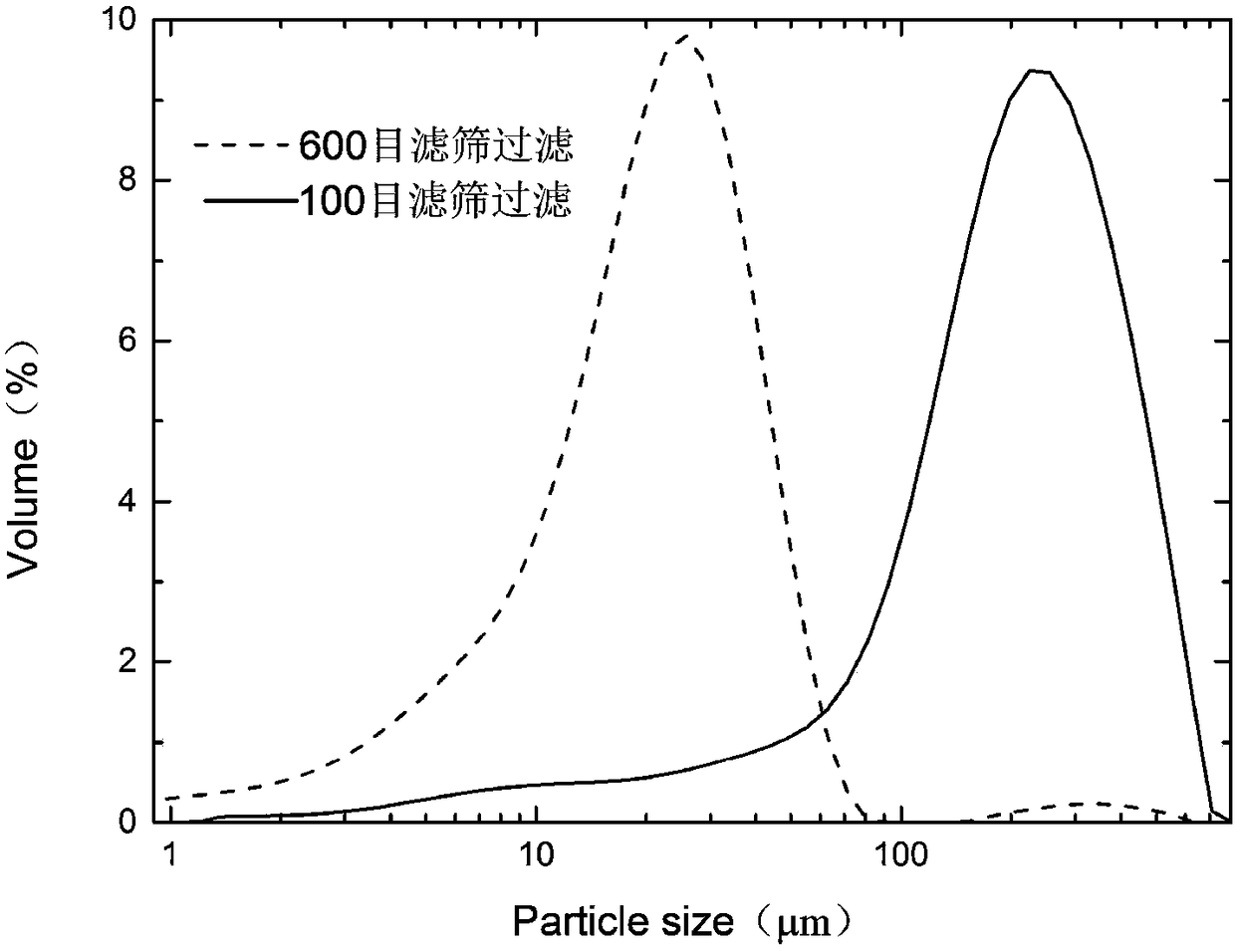

[0020] Step 1: Take 3 to 20 g of zirconium boride with a purity of 99.9% and put it into a BN crucible, compact it manually, numbered 1; take another 5 parts of zirconium boride accounting for 96%, boron carbide (purity 97.97%, carbonization in Mudanjiang City, Heilongjiang Province) Boron factory) accounted for 4%, ball milled in alcohol for two hours, mixed and dried 20-100g of each sample, and then took 3-20g from one of the samples and put them into a BN crucible, compacted by hand, numbered 2. Add 4% PVAL glue to each of the remaining 4 samples, put them into crucibles and grind for 20 minutes to mix well, use 100 or 200 mesh filter sieves to collect and load the samples, and then take 3g of each sample, numbered 3 to 6, and take out The 4 samples were loaded into 4 BN crucibles after using 5MPpa, 10MPa, 15MPa, 20MPa pressure rings on the hydraulic press, and the pressure holding time was 10 seconds.

[0021] Step 2: Put the samples No. 1 to 6 in the previous step into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com