A kind of small square double-sided woolen fabric and its production method

A technology of double-sided wool and small squares, which is applied in the fields of fabric surface trimming, textile material processing, liquid/gas/steam textile material processing, etc. It can solve the problem of not highlighting the color of lines, weaving ordinary weaves in a single way, and taking a long time and other problems, to achieve the effect of clear lines, bright colors, and beautiful connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples.

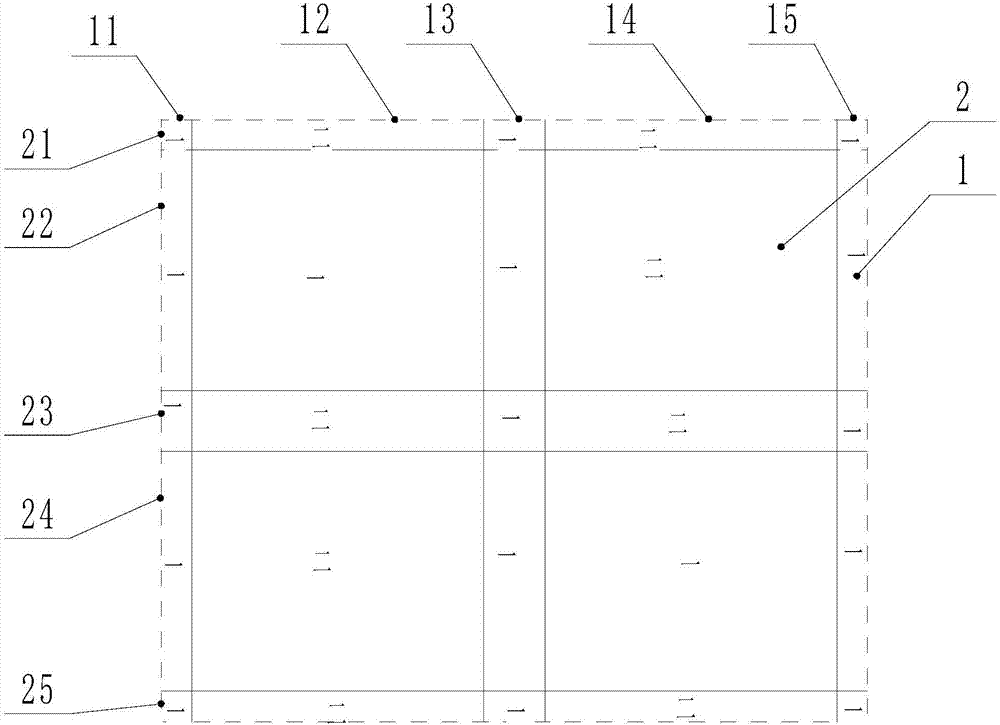

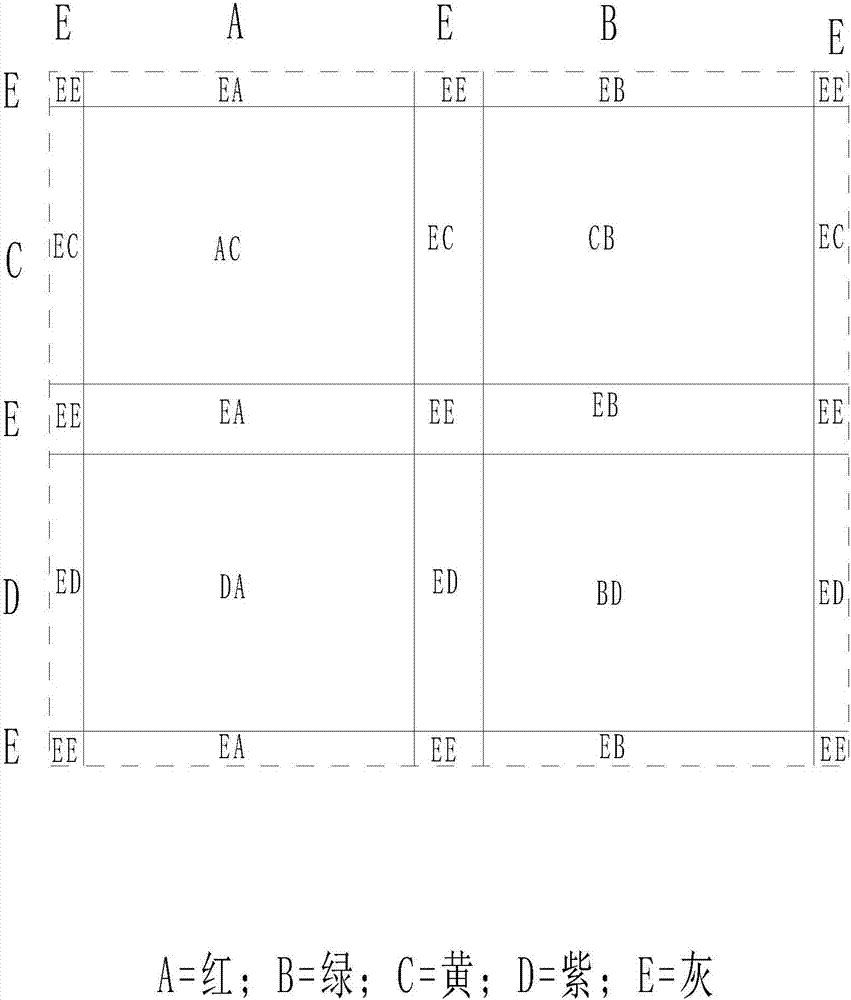

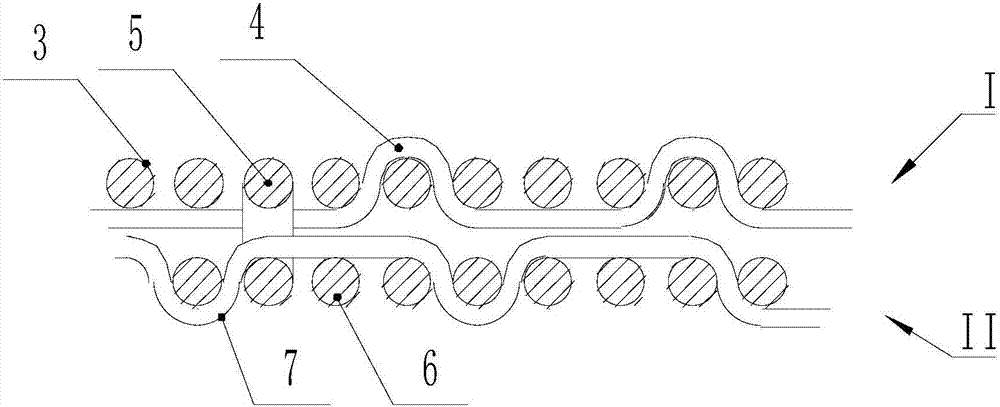

[0035] Such as Figure 1 to Figure 6 As shown, a small square double-faced woolen fabric includes an upper fabric I and a lower fabric II blended by wool fibers and PTT fibers, wherein the wool fibers are Australian wool with a content of 80% and PTT fibers 20%. The lower fabric II includes a solid-color fabric interwoven with gray lower warp yarns 6 and gray lower weft yarns 7 , and the lower fabric II is the second interweaving region 2 as a whole. That is, the three lower warp yarns 6 are on top of the next lower warp yarn 6, and are interwoven in a right twill pattern, and the entire lower layer fabric II is gray.

[0036] The upper fabric 1 includes several grid units that are distributed repeatedly, and the grid units successively include the first warp connection area 11, the first warp direction area 12, the middle warp direction connection area 13, the second warp dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com