Anticorrosive low-humidity walk-in test chamber

A walk-in, test box technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of rust everywhere in the inner box, refrigerant leakage in the refrigeration system, corrosion, etc., to prolong the service life, The effect of good anti-corrosion function and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

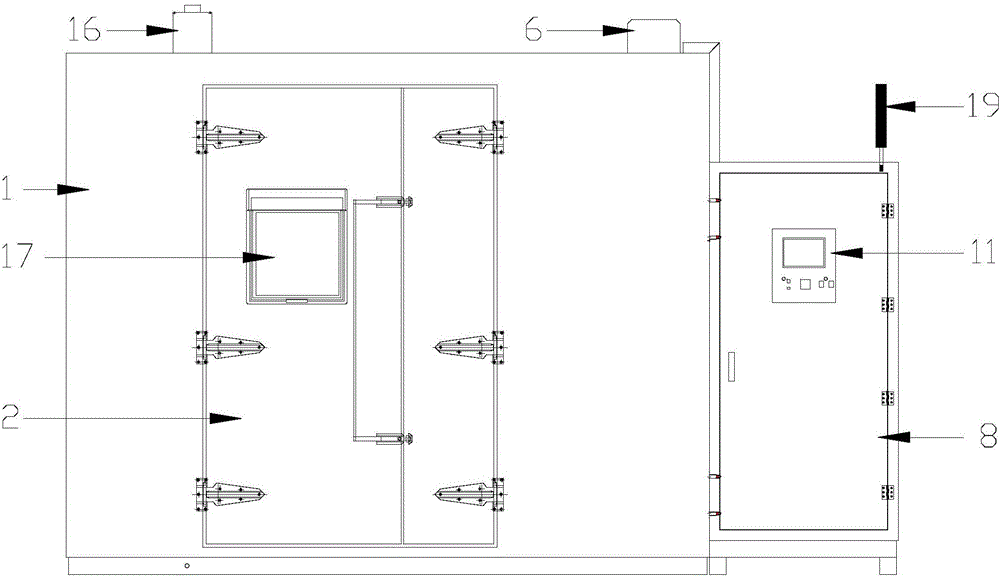

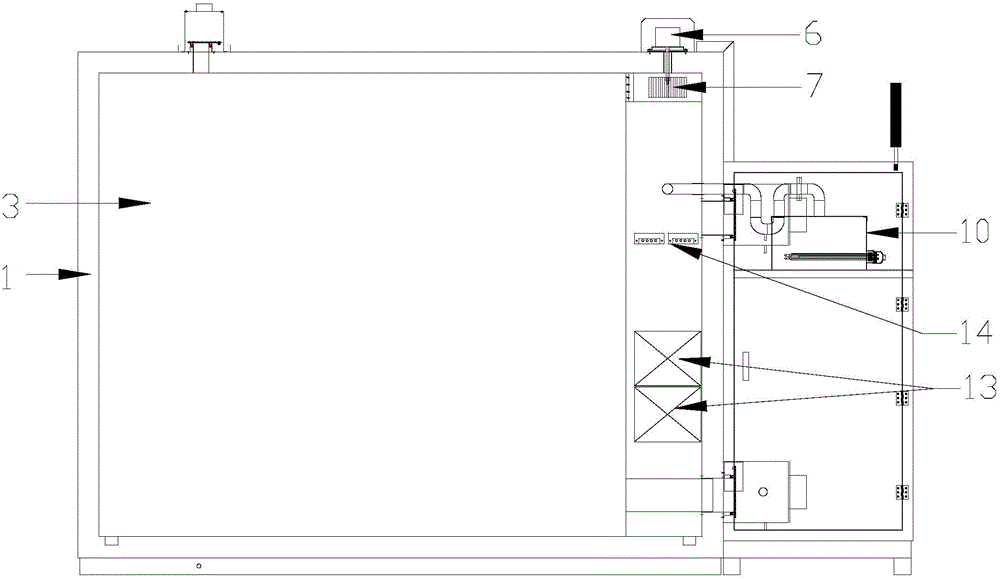

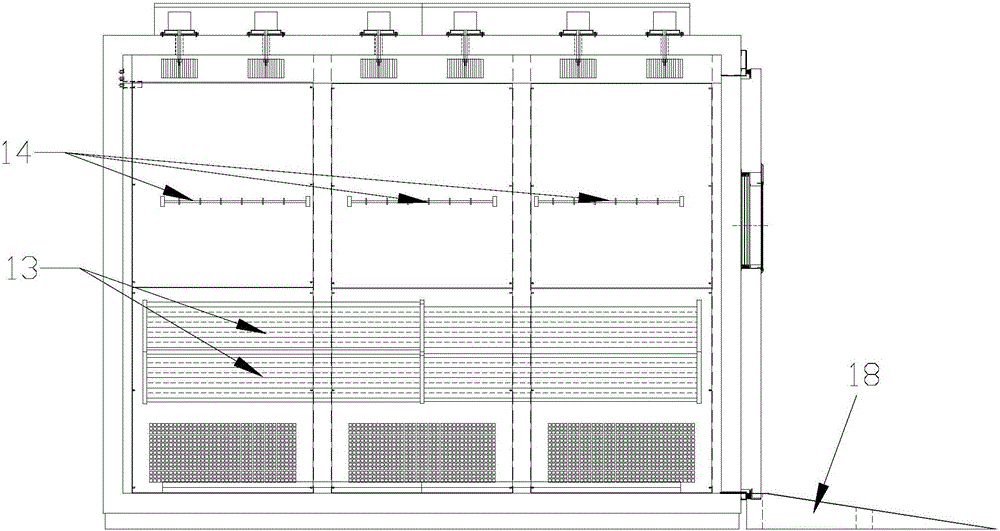

[0029] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0030] As shown in the drawings, the present invention includes: a box body 1, a heating system, a humidification and dehumidification system, a refrigeration system and an electrical system. A box door 2 is provided on the front end of the box body 1, and a working chamber 3 is arranged in the box body 1. Room 3 is equipped with a temperature and humidity circulation system and a ventilation system. The ventilation system includes an air inlet valve 4, an air inlet valve 5, a filter and a dryer. The side of the box body 1 is provided with an air inlet and an air inlet. , the air inlet is equipped with an air inlet valve 4, the air inlet is equipped with an air inlet valve 5, the inner side of the air inlet is provided with a filter, the air outlet end of the filter is equipped with a dryer, and the outlet of the dryer The air end communicates with the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com