Method and system for detecting faults of high-speed railway signal system

A signal system and fault detection technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of fault expansion, lack of data mining and reuse, single function, etc., and achieve the effect of an efficient fault detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

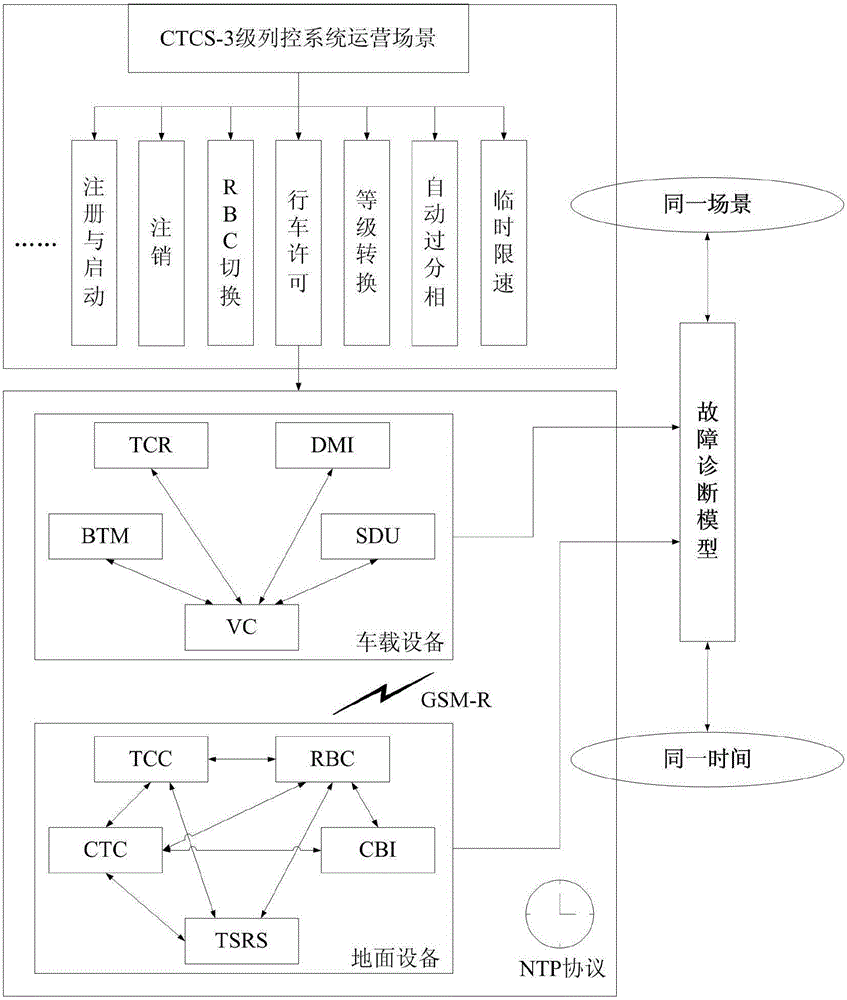

[0047] The preferred implementation examples will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

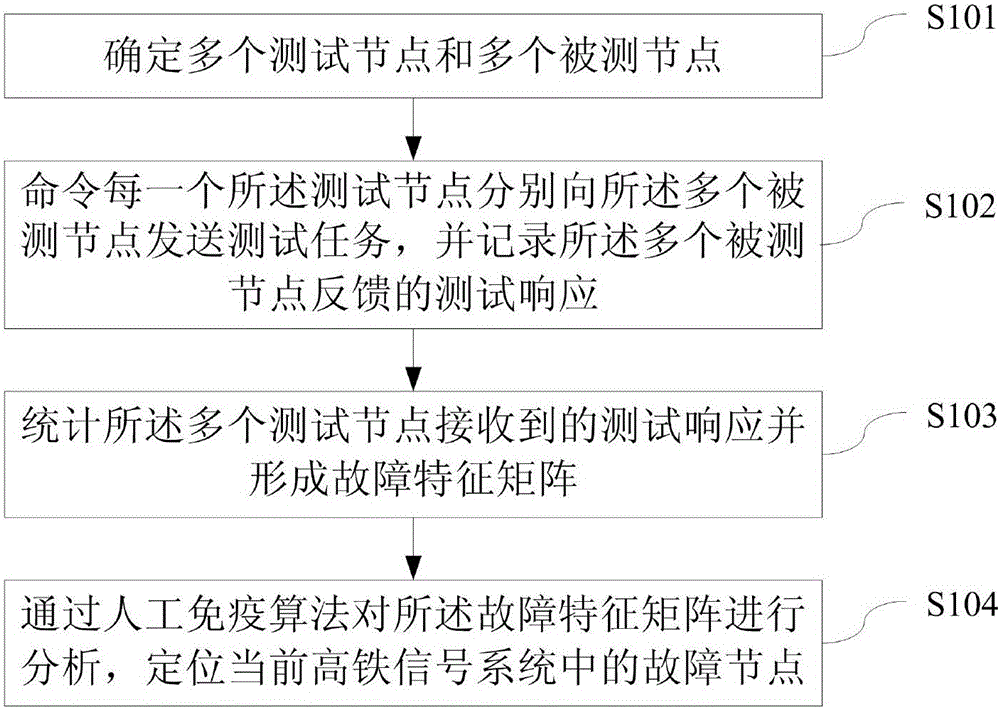

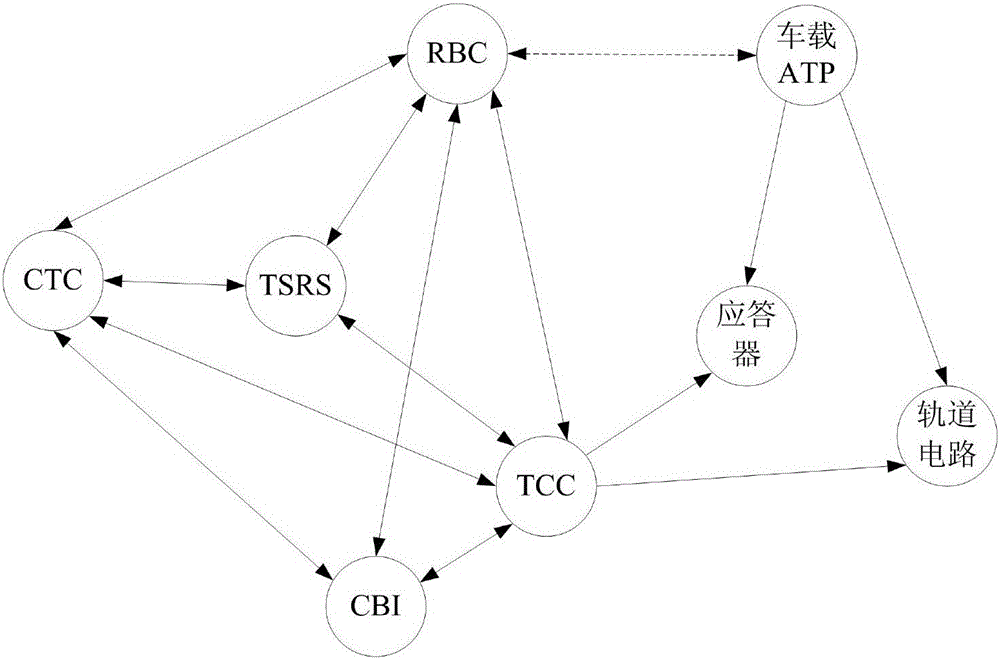

[0048] The fault detection and location of the high-speed rail signal system level are mainly divided into two stages: the test stage and the detection stage (also called the diagnosis stage). In the test phase, a system detection model is established according to the characteristics of the signal system, and corresponding test rules are formulated to obtain test results between nodes in the system; in the detection phase, a suitable detection algorithm is found based on the test results, and the faulty node is obtained by solving the problem. It should be noted that after the test results are obtained, the necessity of the detection process lies in: during the test process, there will be faulty nodes parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com