A Scheduling Optimization Method Based on Flexible Scheduling

An optimization method and a flexible technology, applied in the direction of program control, electrical program control, control/regulation system, etc., can solve the problems of difficulty in arranging the sequence, considering the factors that stir production, complexity, and many factors that affect production, and achieve reduction The effect of reducing production idle time, reducing production energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

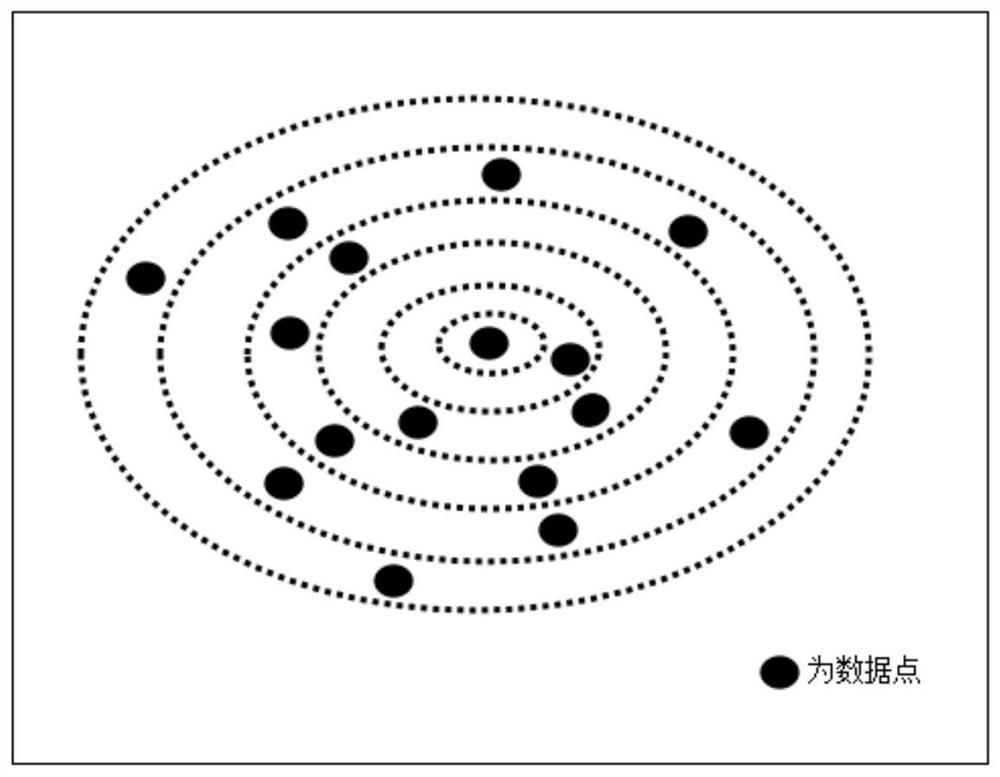

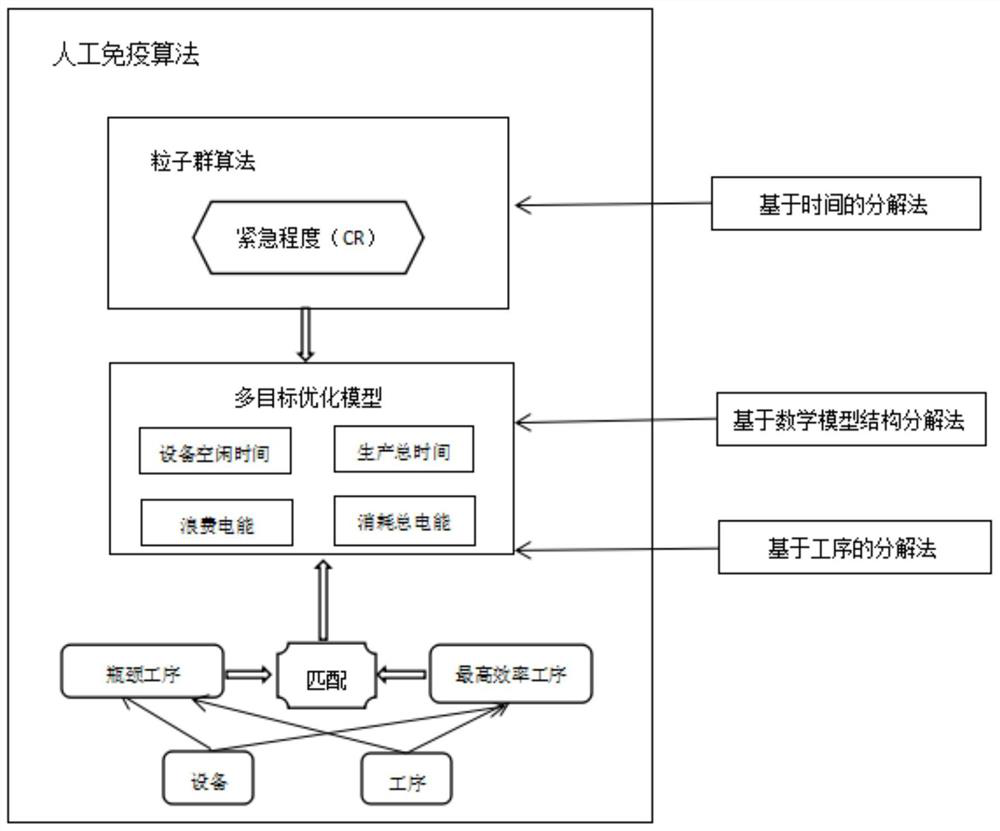

[0063] In the design process of the scheduling optimization method based on flexible scheduling in the present invention, the optimization algorithm uses a full amount of data. In the particle swarm optimization algorithm, the present invention regards the full amount of data as all data points in a closed two-dimensional space, wherein each data point contains multiple sub-points, first find a certain data point as the optimal data point, and Take a certain subpoint of the data point as the global optimal point and take it out, then merge this data point with the next optimal data point, find the next optimal point in the merged subpoint, and pass it on in turn to form one such as figure 1 The data processing structure of the swirl is shown. In other parts of the model, the structural form of sequentially processing data points in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com