Outer-hanging touch display device with pressure-sensing touch function

A touch display and touch function technology, which is applied in the field of plug-in touch display devices, can solve the problems of high process difficulty, affect the display quality of the display, complicated structure, etc., and achieve the effects of low production cost, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

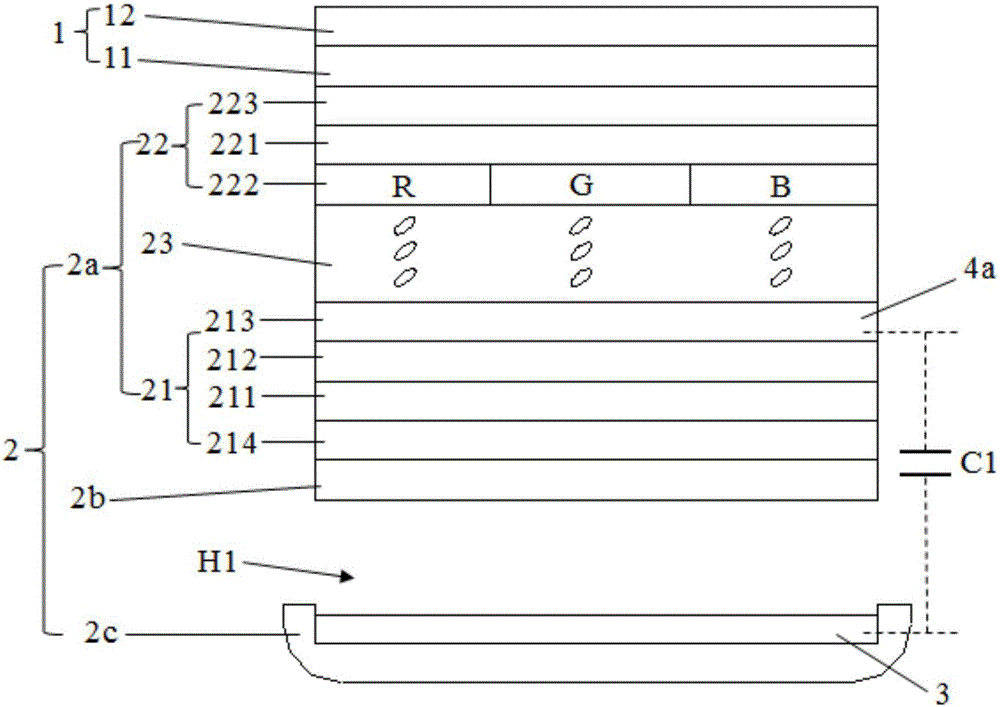

[0024] This embodiment provides an external touch display device with a pressure-sensitive touch function, such as figure 1 As shown, the plug-in touch display device includes a capacitive touch screen 1 and a display module 2 arranged in layers.

[0025] Wherein, the capacitive touch screen 1 includes touch driving electrodes 11 and touch sensing electrodes 12 arranged in different layers, and the touch driving electrodes 11 and touch sensing electrodes 12 are used for sensing touch signals applied on the capacitive touch screen 1 .

[0026] Wherein, the display module 2 includes a display panel 2a and a backlight module 2b arranged oppositely, and a middle frame 2c for supporting the display panel 2a and the backlight module 2b, and the backlight module 2b provides a display light source for the the display panel 2a, so that the display panel 2a displays images.

[0027] Wherein, the display panel 2 a includes an array substrate 21 and a filter substrate 22 disposed opposit...

Embodiment 2

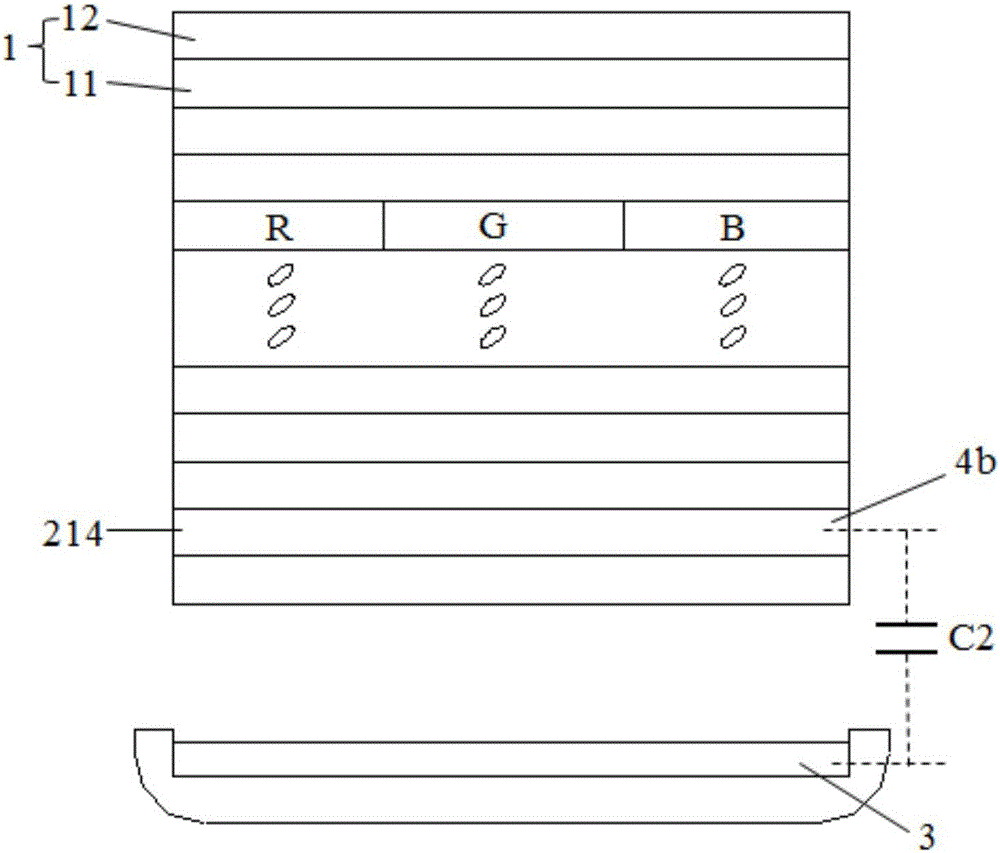

[0032] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, in this embodiment, the first polarizer 214 is made of a conductive material, and the first polarizer 214 is used as the first capacitance sensing electrode 4b, and the first capacitance sensing electrode 4b and The second capacitive sensing electrode 3 constitutes a capacitive sensing mechanism C2, and the capacitive sensing mechanism C2 is connected with a pressure sensing control chip (not shown in the drawings) for sensing a pressure signal applied to the touch display device.

[0033] Specifically, in the touch display device, the touch control chip drives the touch driving electrodes 11 and the touch sensing electrodes 12 of the capacitive touch screen 1 to sense the touched position. The first capacitive sensing electrode 4b and the second capacitive sensing electrode 3 are driven by the pressure sensing control chip, and when the touching finger presses the capacitive touch s...

Embodiment 3

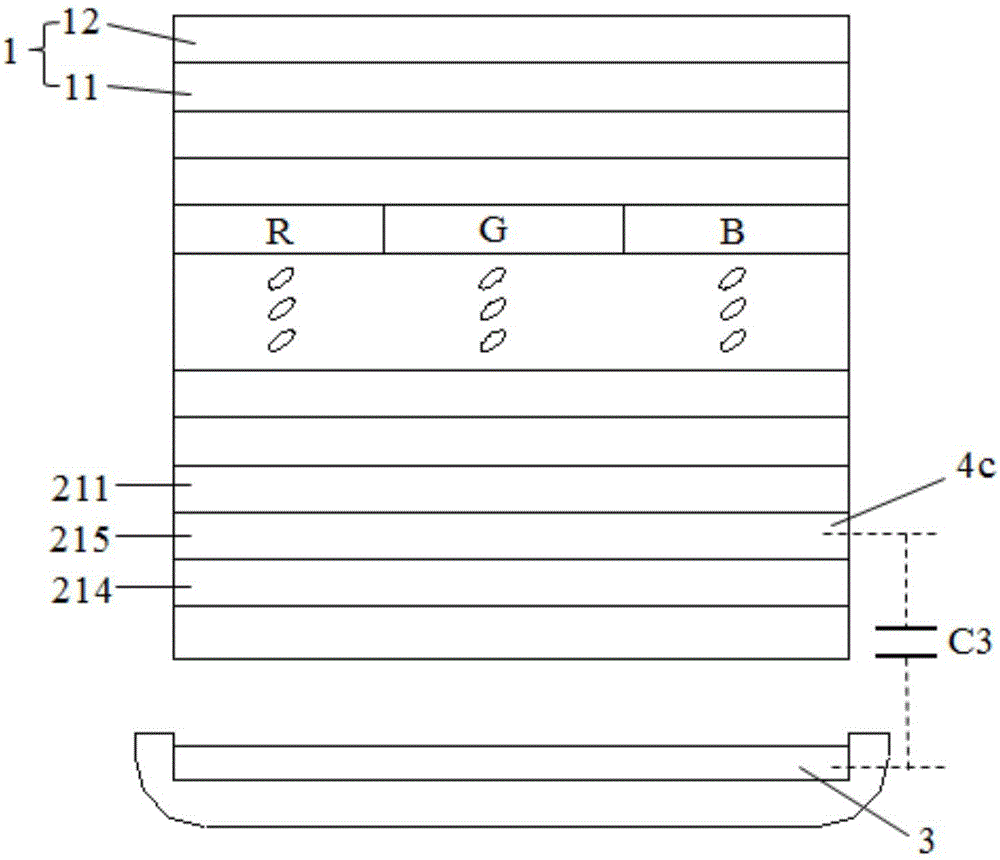

[0035] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, in this embodiment, a first conductive plane 215 is provided between the first polarizer 214 and the first glass substrate 211, and the first conductive plane 215 is used as the first capacitive sensing electrode 4c , the first capacitive sensing electrode 4c and the second capacitive sensing electrode 3 form a capacitive sensing mechanism C3, and the capacitive sensing mechanism C3 is connected with a pressure sensing control chip (not shown in the drawings) for sensing the pressure applied to the touch Displays the pressure signal on the device. Wherein, the first polarizer 214 is made of insulating material, and the material of the first conductive plane 215 is indium tin oxide (ITO).

[0036] Specifically, in the touch display device, the touch control chip drives the touch driving electrodes 11 and the touch sensing electrodes 12 of the capacitive touch screen 1 to sense the tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com