Supporting bracket for inserting piece

A technology for supporting brackets and inserts, which is applied in the field of transformers and can solve problems such as cracking of epoxy resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

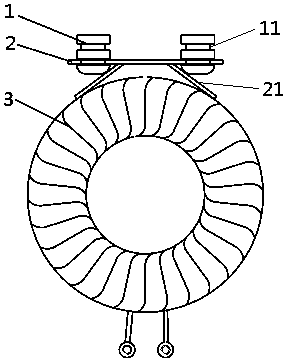

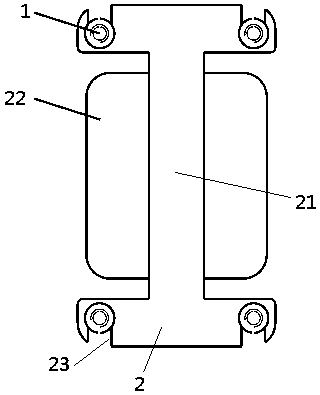

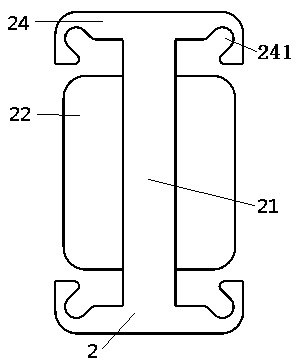

[0013] A specific embodiment of the insert support bracket of the present invention, such as image 3 shown. figure 1 It shows the use state diagram of the insert support bracket, 1 is the insert, 2 is the bracket, 3 is the secondary winding, and the insert 1 is provided with a ring groove 11 . The insert support bracket 2 includes a bracket base 21 , two side support plates 22 , and four support guide grooves 241 . The bracket base 21 includes two installation support plates 24 and a web connected between the two installation support plates 24. The guide slots 241 and the support guide slots 241 are U-shaped, and the openings of the four support guide slots 241 face the web and are in the same direction as the curing and shrinkage of the epoxy resin at their positions. Both sides of the web of the bracket base 21 are symmetrically provided with side support plates 22, in order to increase the contact area between the insert support bracket 2 and the secondary winding 3, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com