Motor stator structure

A motor stator and positioning column technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of uneven solder joint size, motor failure, low production efficiency, etc., achieve consistent solder joint size, stable product quality, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

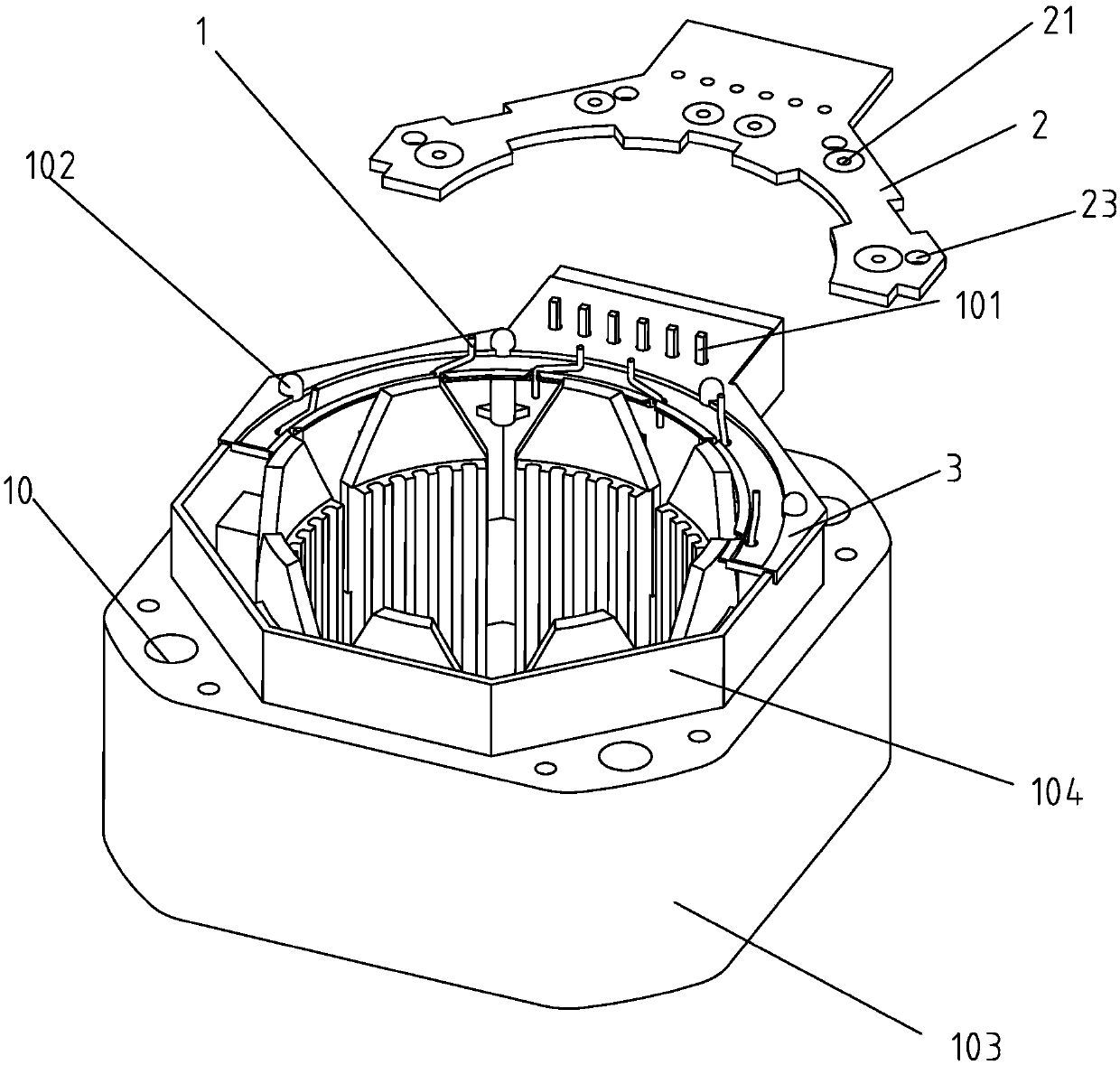

[0026] Such as figure 1 , 2 As shown, a motor stator structure, which includes:

[0027] A main body part 10, the main body part has a winding wire 1; there are multiple winding wires 1, and the number thereof is not limited;

[0028] A circuit board 2, the circuit board 2 is installed on the main body part 10;

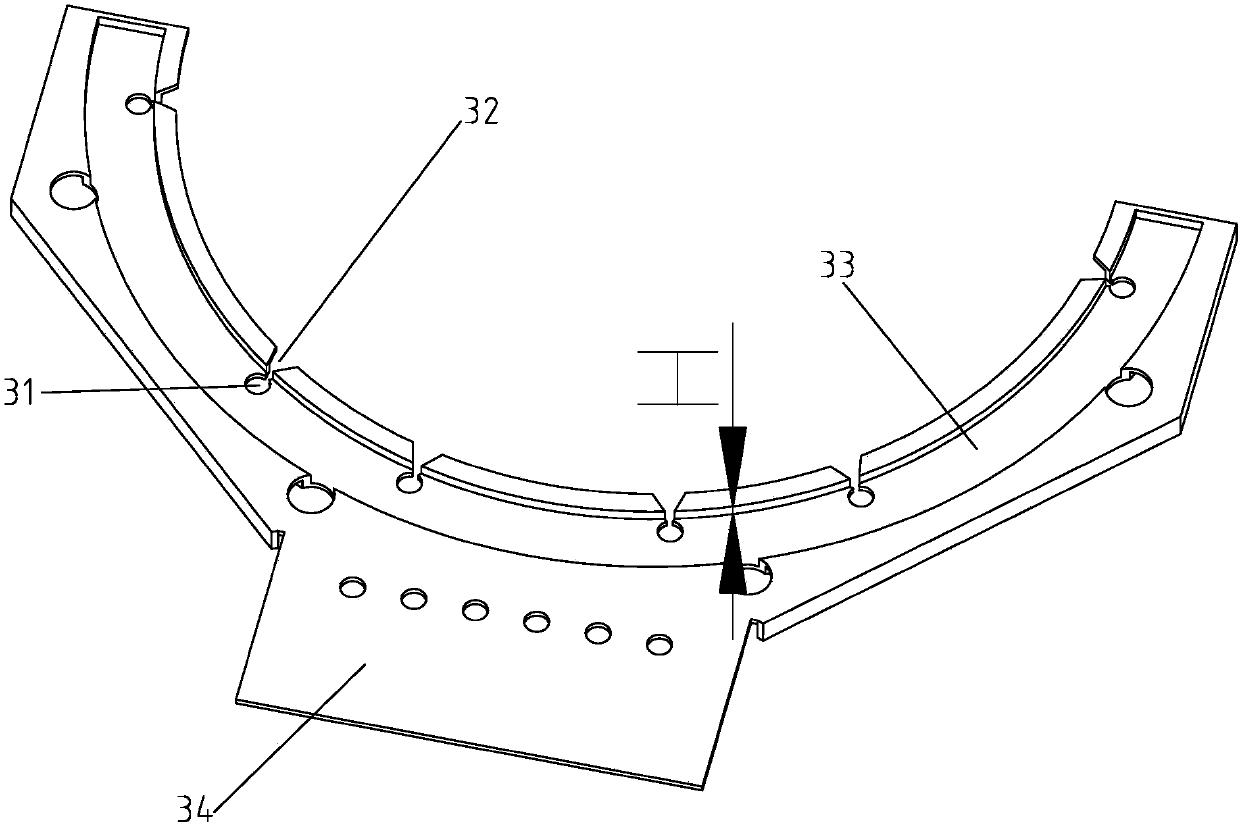

[0029] Tin blocking cover 3, the tin blocking cover 3 is arranged between the main part 10 and the circuit board 2, and the winding wiring 1 connected from the main part 10 is first snapped into the tin blocking cover 3, and then connected to the circuit board 2 .

[0030] Since the tin shielding cover 3 is added between the main part 10 and the circuit board 2, it not only solves the phenomenon of tin leakage when the hole diameter on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com