Air spring assembly having integrated control valve and rod-shaped actuating element

A technology for air springs and control valves, applied in springs, vehicle springs, springs/shock absorbers, etc., can solve problems such as unrestricted switching positions, and achieve the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

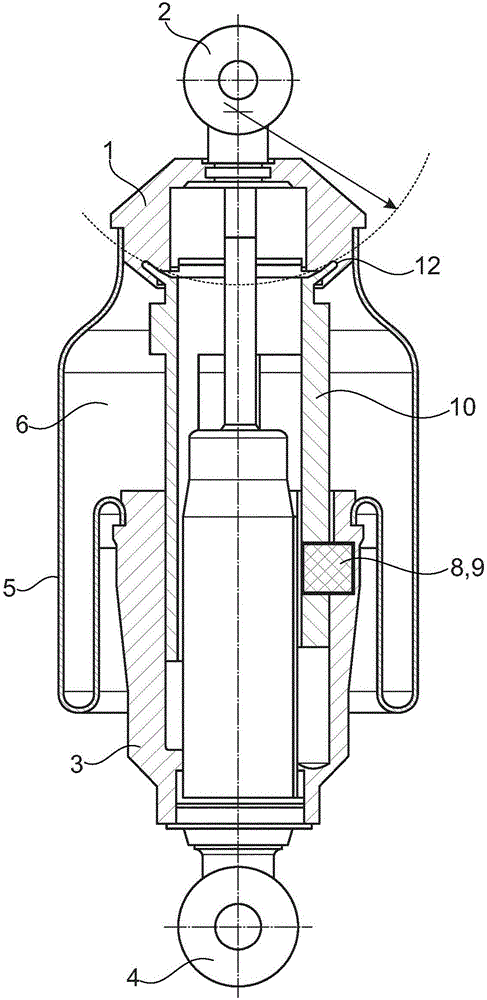

[0025] according to figure 1 , the air spring assembly mainly consists of an outer tube 1 with an upper fixing ring 2 and a rolling tube 3 with a lower fixing ring 4 for mounting on the driver's cab of a commercial vehicle not further shown, the The lower retaining ring is used in air spring assemblies mounted on commercial vehicle frames. The outer tube 1 and the rolling tube 3 are connected through the air spring air bag 5 , so that a spring pressure chamber 6 is formed between the outer tube 1 , the rolling tube 3 and the air spring air bag 5 . This air spring cooperates with an integrated hydraulic shock absorber 7 for damping the sprung mass.

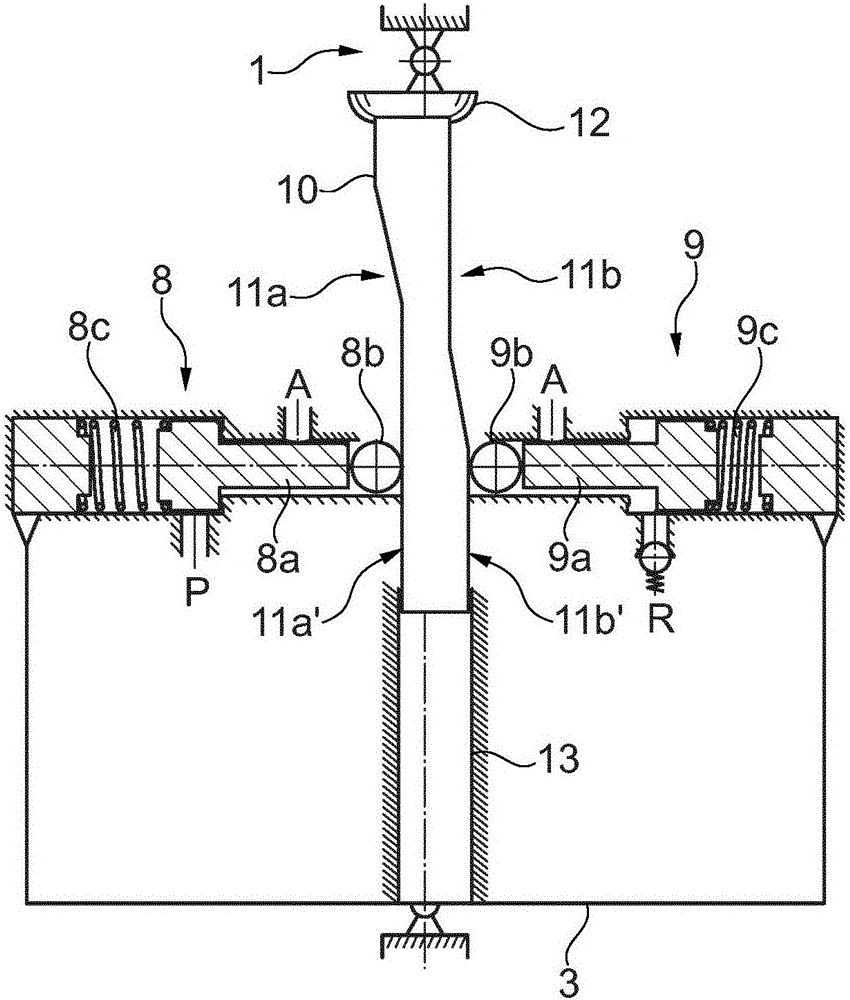

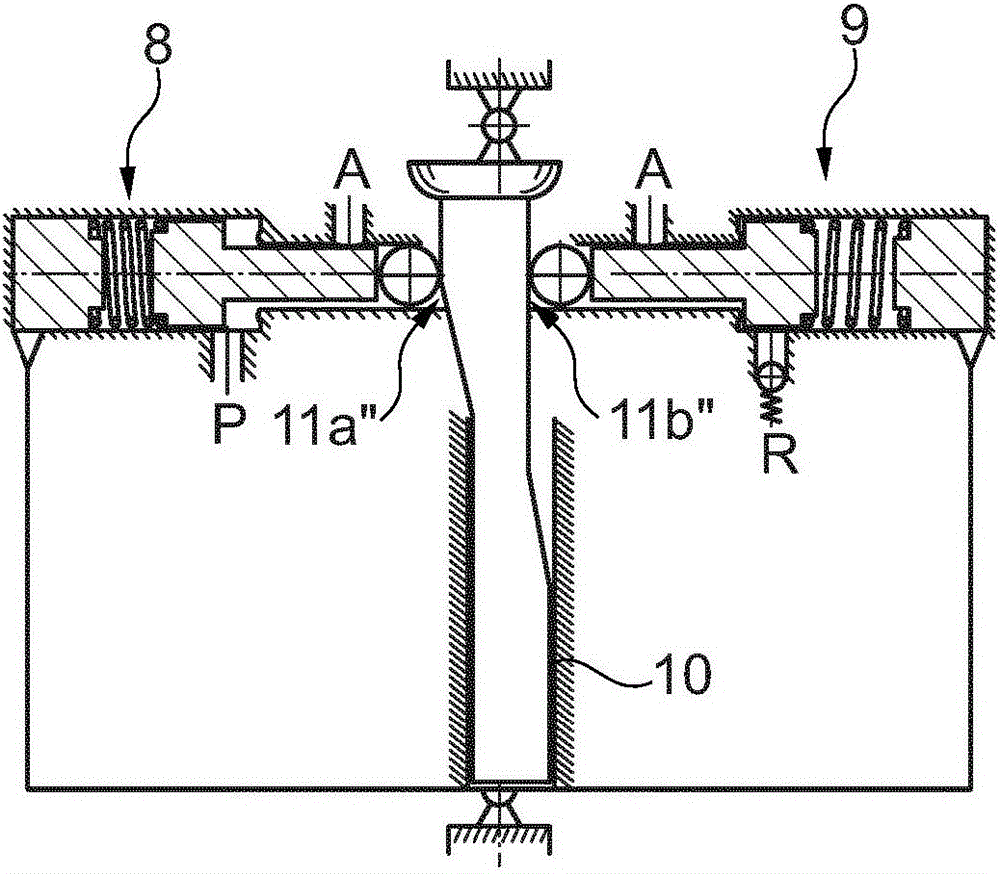

[0026] The spring pressure chamber 6 of the air spring assembly can be loaded with compressed air via an integrated control valve assembly consisting of a single vent valve 8 and a single vent valve 9 . The ventilation valve 8 and the exhaust valve 9 can be actuated according to the air spring travel position by means of likewise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com