Patents

Literature

47results about How to "No overflow loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

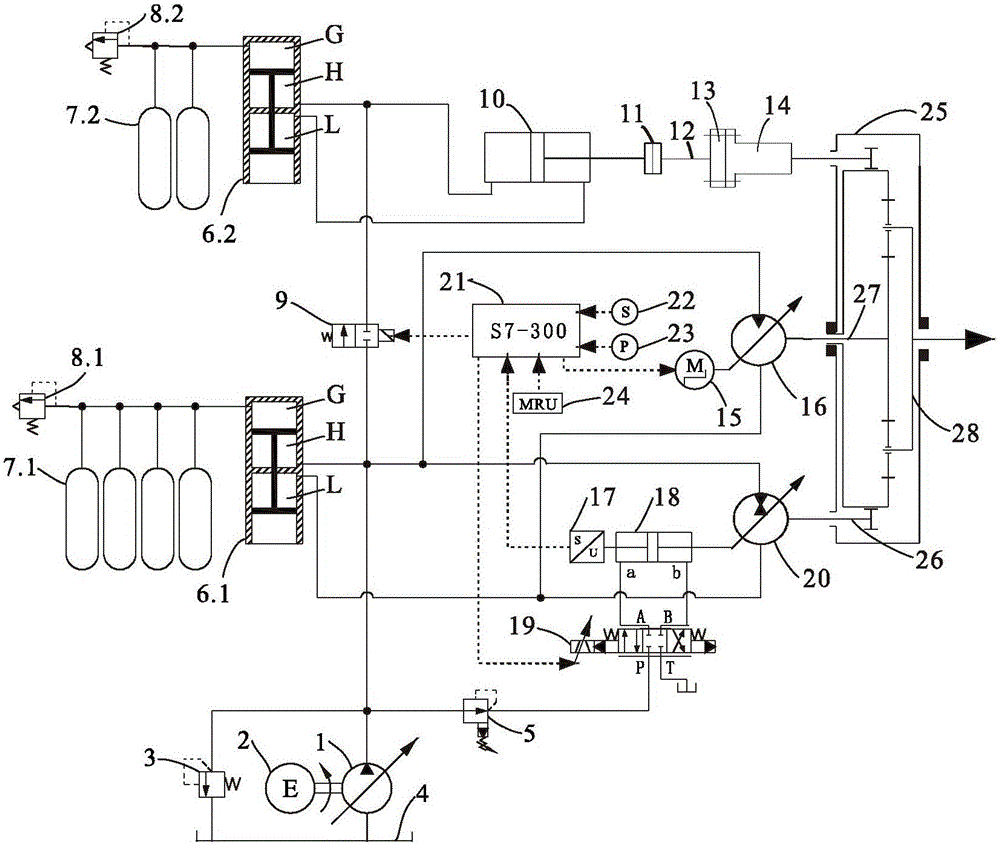

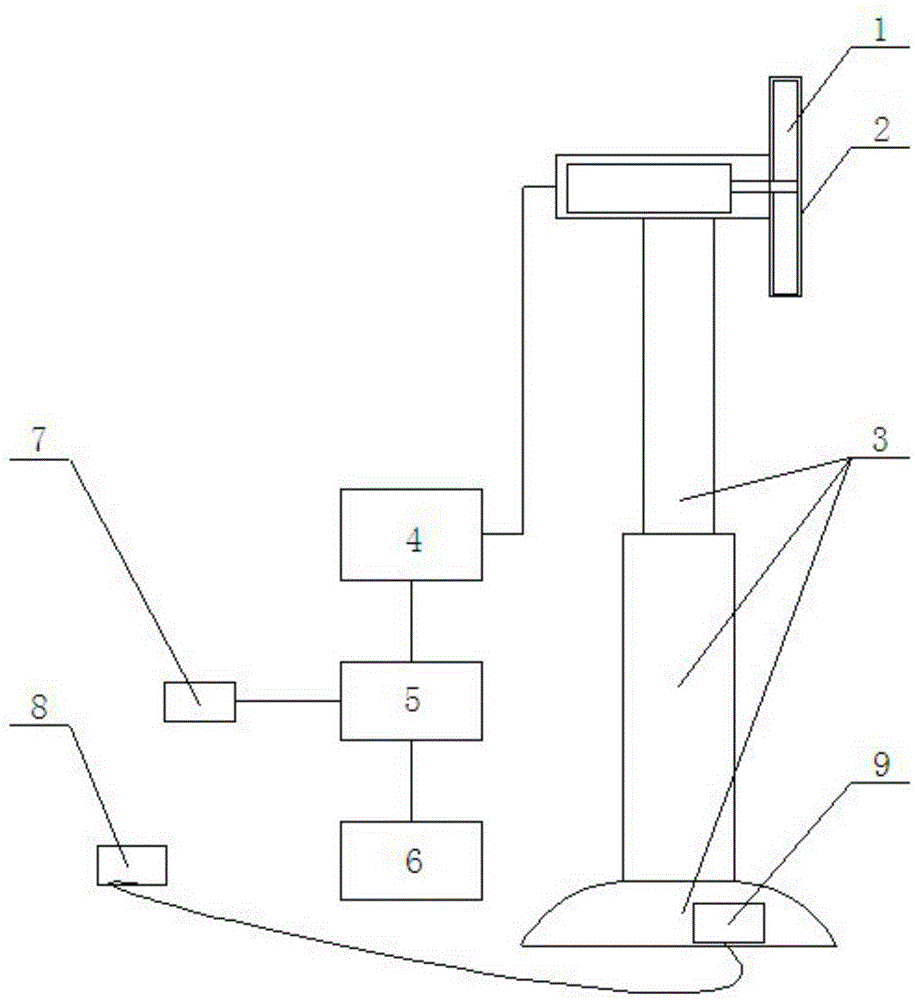

Hydraulic driving system for offshore drilling compensation winch

ActiveCN105804675AReduce loadReduce extra spaceDrilling rodsServometer circuitsEngineeringEnergy recovery

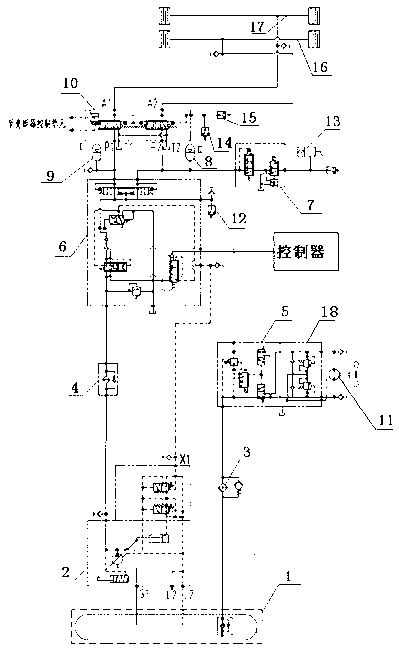

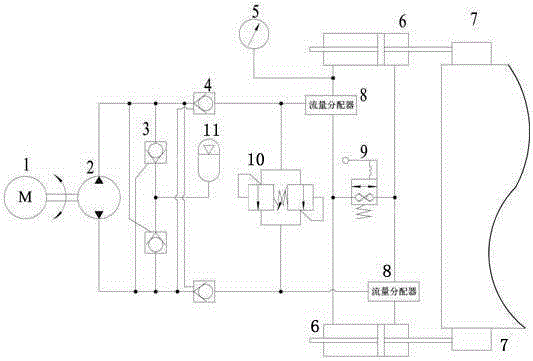

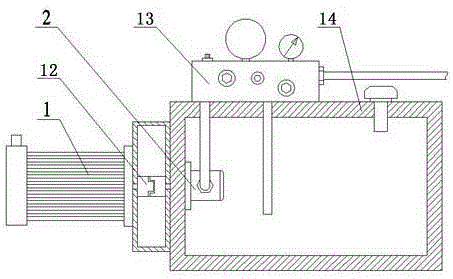

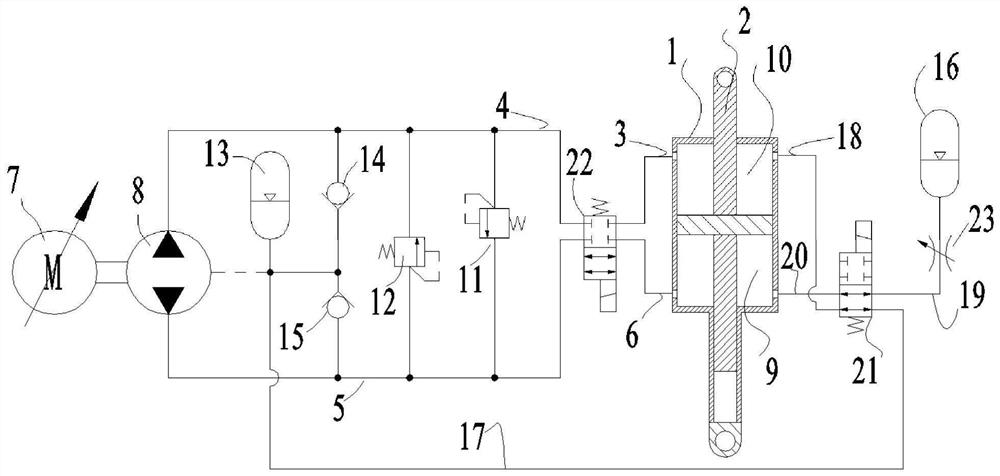

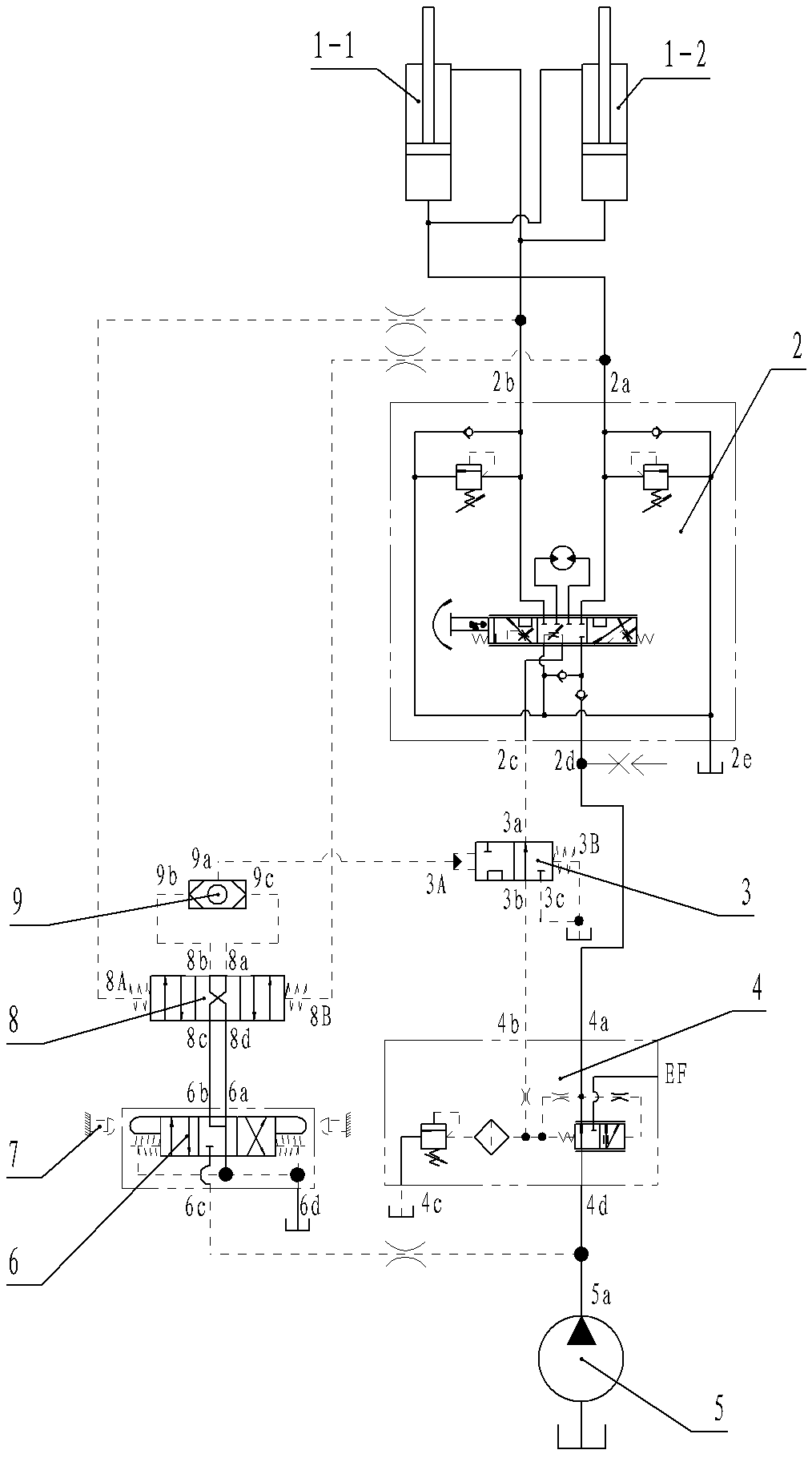

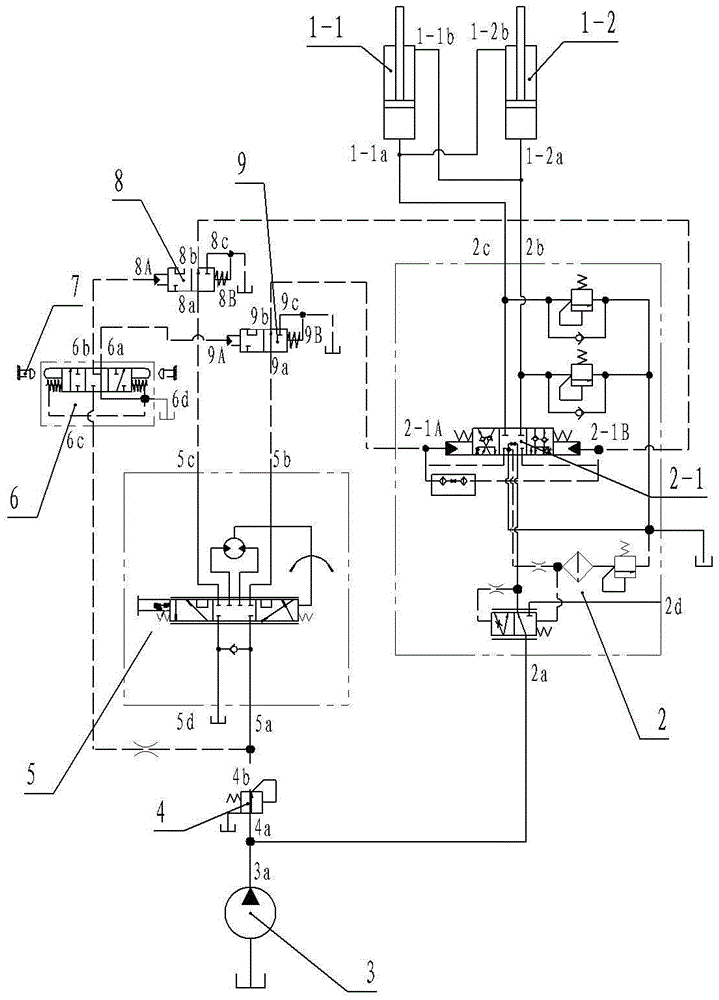

The invention discloses a hydraulic driving system for an offshore drilling compensation winch.A hydraulic secondary regulation element and a driven hydraulic cylinder jointly drive the winch to fulfill a heave compensation function, and a bit feeding hydraulic motor drives the winch to fulfill an automatic bit feeding function.During compensation, the driven hydraulic cylinder and a liquid-gas energy storage device thereof are used or bearing all static loads of a drilling rig and periodically recovering and releasing gravitational potential energy of loads; the hydraulic secondary regulation element operates in a constant-pressure network to overcome other loads in the compensation process, and the liquid-gas energy storage device periodically recovers and releases inertia kinetic energy of the a winch rotary system.During bit feeding, the driven hydraulic cylinder and the liquid-gas energy storage device thereof recover the gravitational potential energy of the loads of the drilling rig and release in lifting of a drilling rig traveling system.The hydraulic driving system is integrally compact in structure, a hydraulic energy recovery system is high in operation efficiency and long in service life, and an engine is low in power and power consumption.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

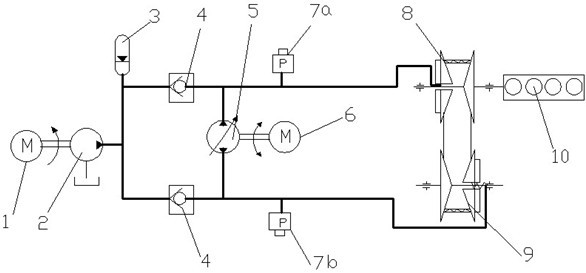

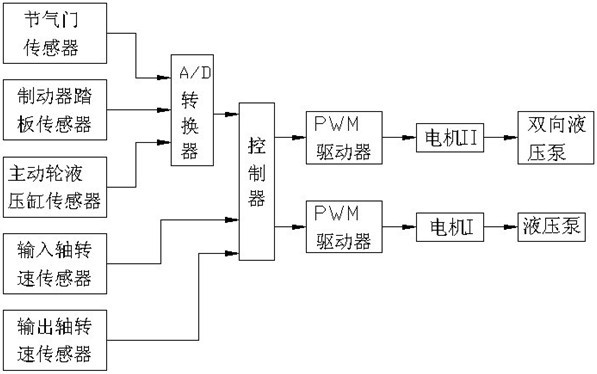

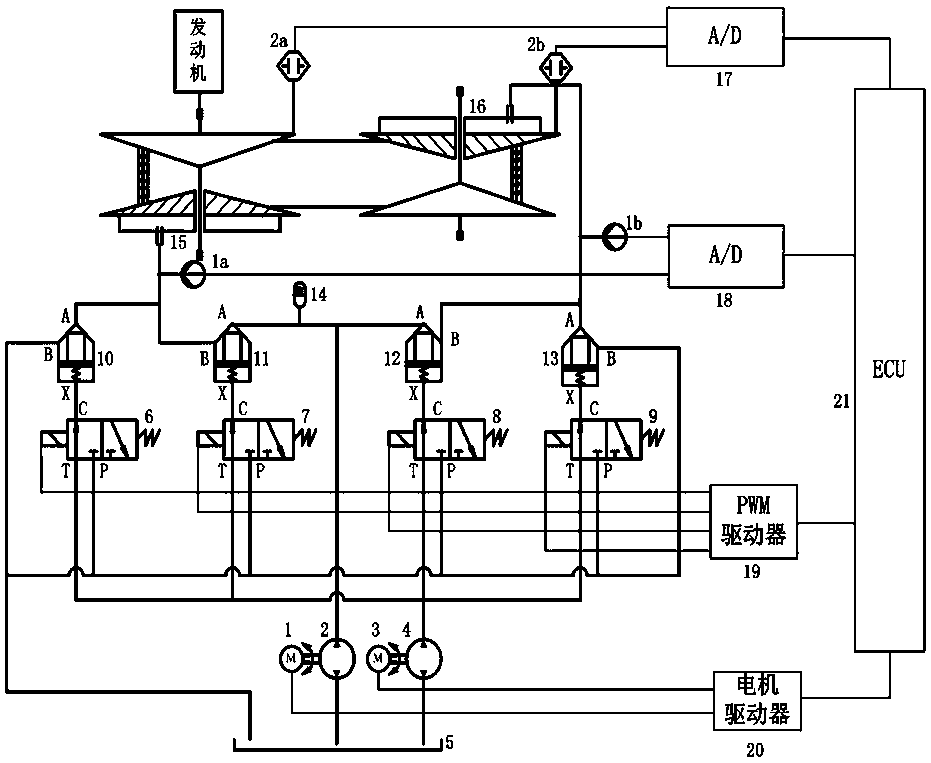

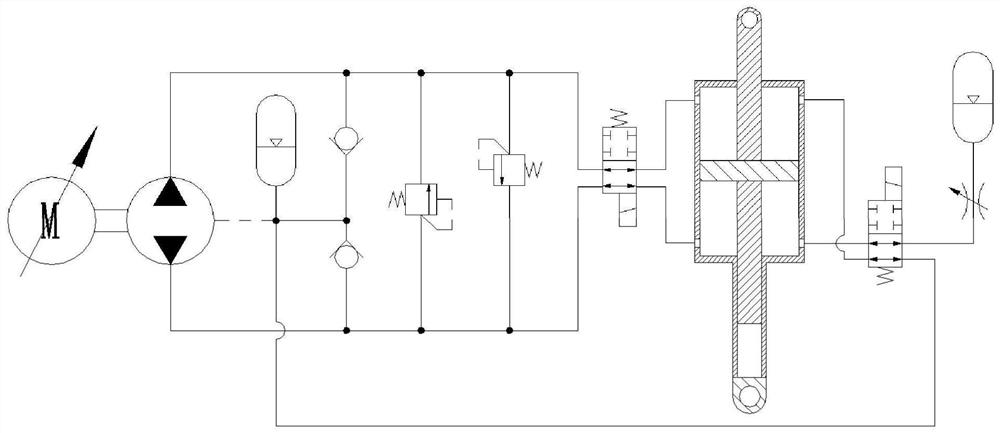

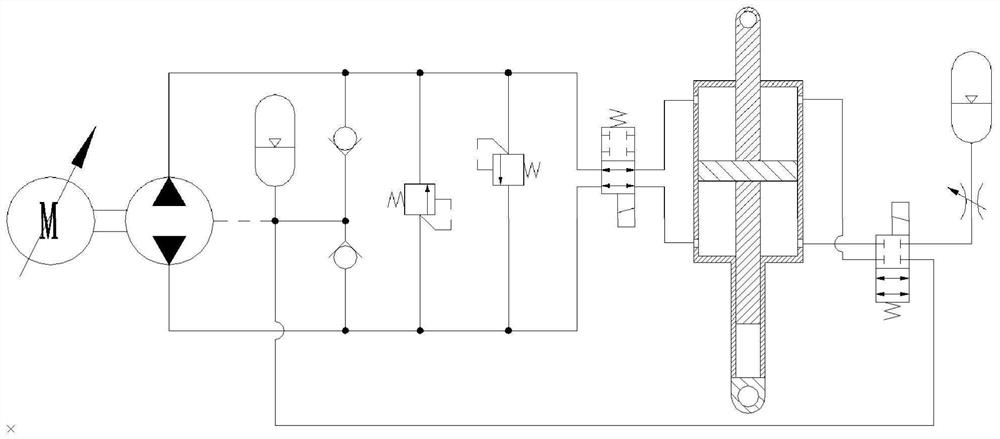

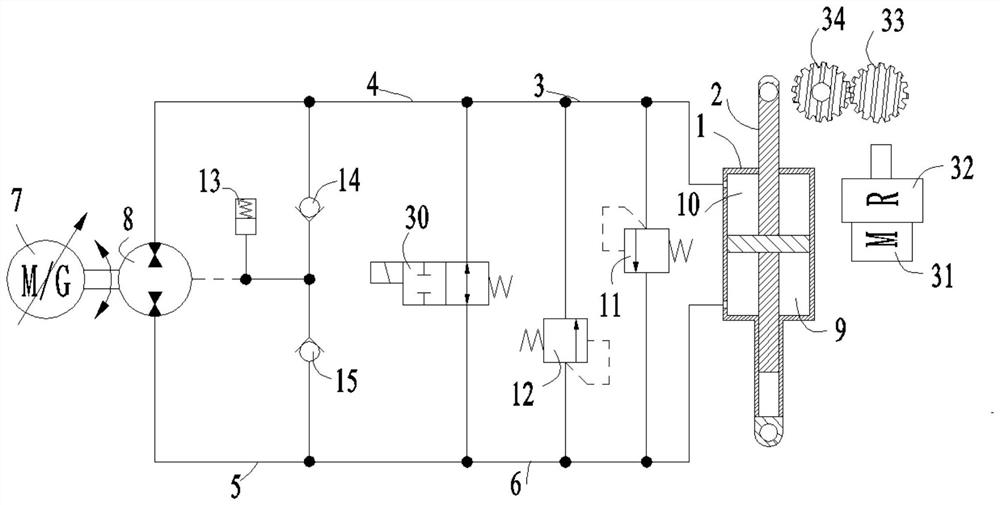

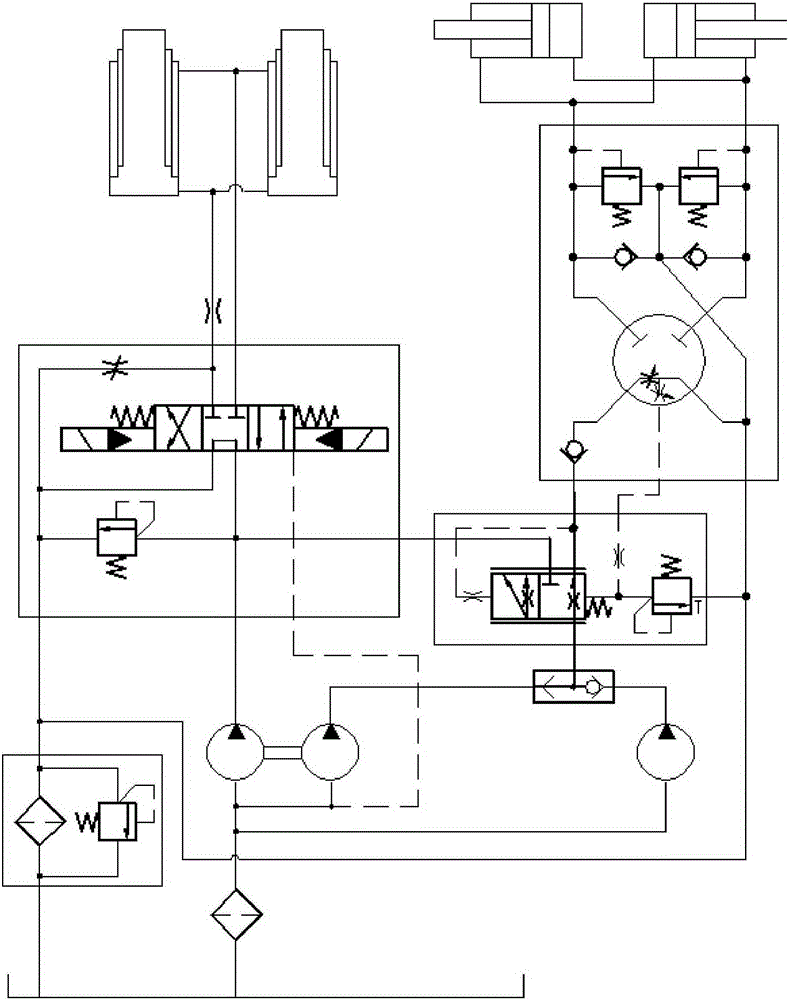

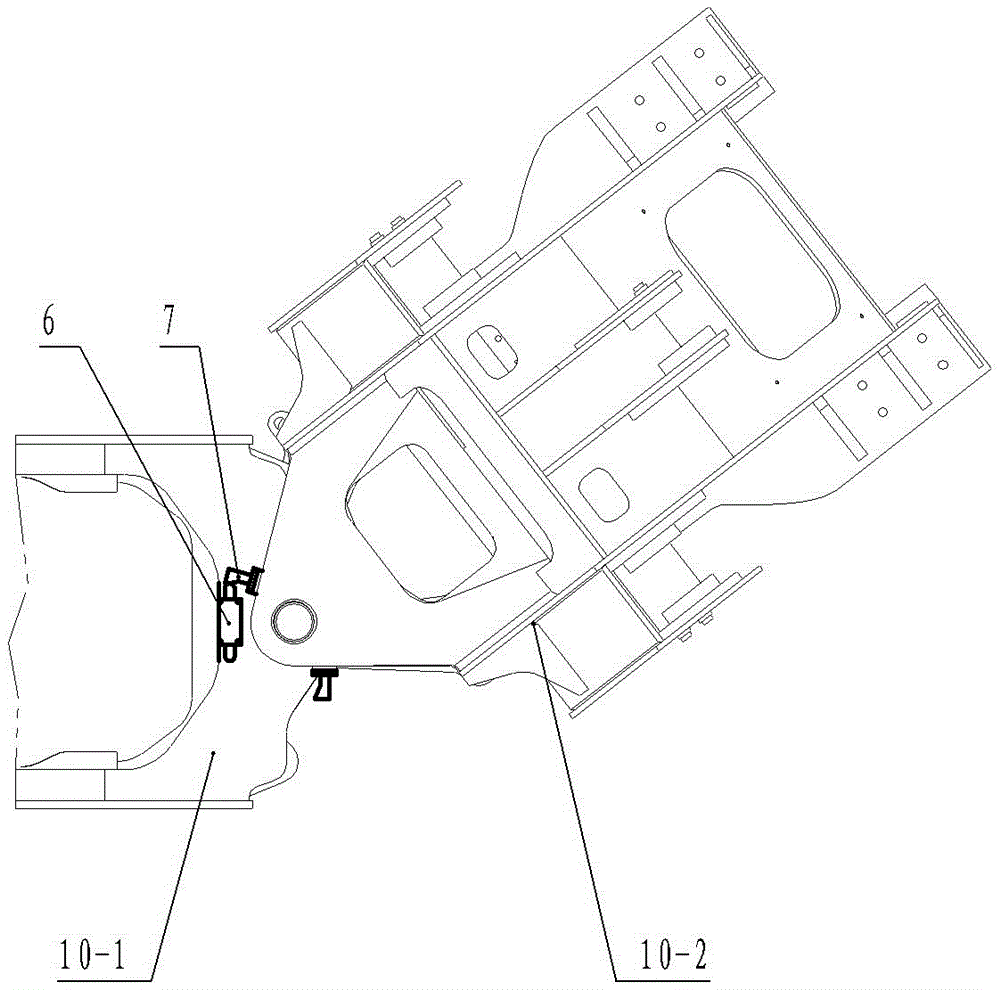

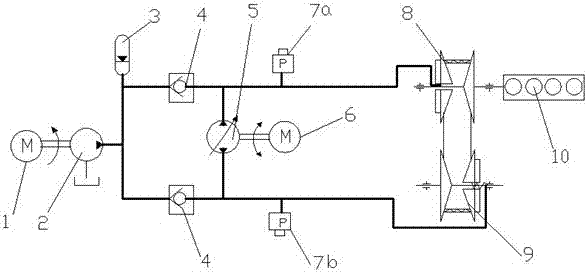

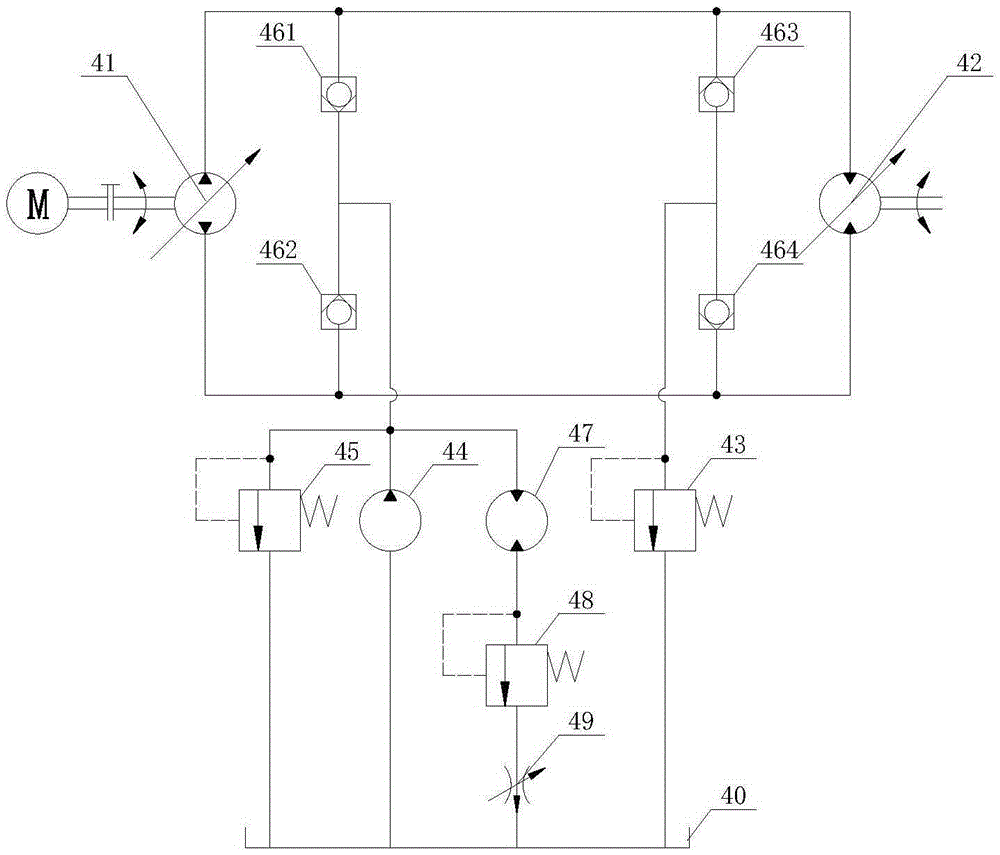

Pump-controlled CVT (continuously variable transmission) electric hydraulic control system

InactiveCN102494128AReduce the pressure difference between inlet and outletReduce consumptionGearing controlHydraulic cylinderDrive wheel

The invention discloses a pump-controlled CVT (continuously variable transmission) electric hydraulic control system, which comprises a driving wheel hydraulic cylinder, a driven wheel hydraulic cylinder, a speed ratio control hydraulic loop, a clamping force control hydraulic loop, a controller and two pressure sensors. Effective areas of the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder are equal; the speed ratio control hydraulic loop comprises a motor II and a bidirectional hydraulic pump, and oil ports of two ends of the bidirectional hydraulic pump are respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder; the clamping force control hydraulic loop comprises a motor I, a hydraulic pump, an energy accumulator and one-way valves; an oil outlet of the hydraulic pump is respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder via the two one-way valves; and two pressure sensors are respectively mounted on pipelines communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder. The oil inlet port and the oil outlet port of the bidirectional hydraulic pump in the speed ratio control hydraulic loop are respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder via pipelines, pressure differences of the inlet port and the outlet port of the bidirectional hydraulic pump is reduced, consumption of power of a speed ratio adjusting hydraulic pump is not high, flow of a pressure control hydraulic pump is quite low, the pressure control hydraulic pump only supplements leakage of the system, and consumed power is lower.

Owner:CHONGQING ACADEMY OF SCI & TECH +1

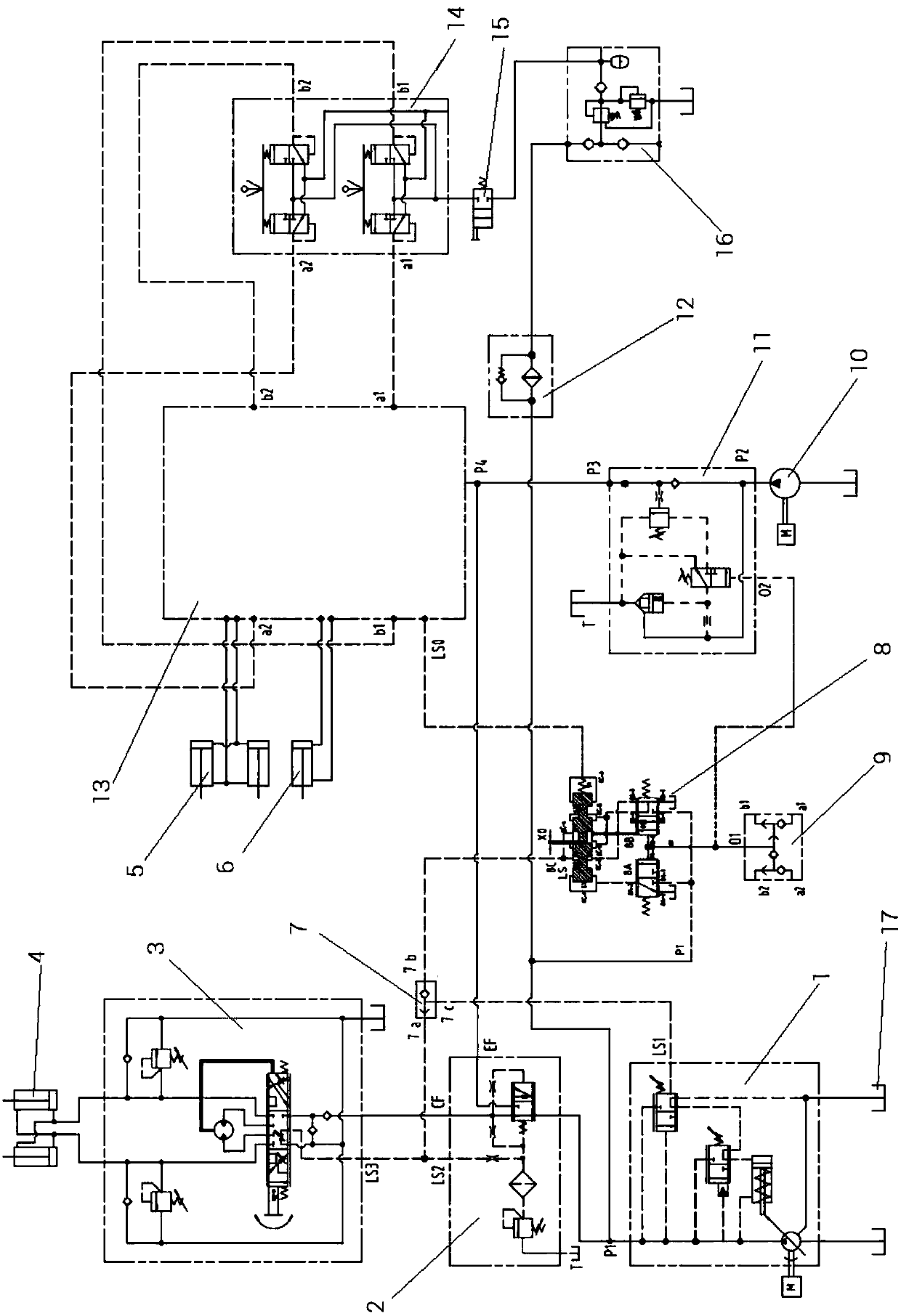

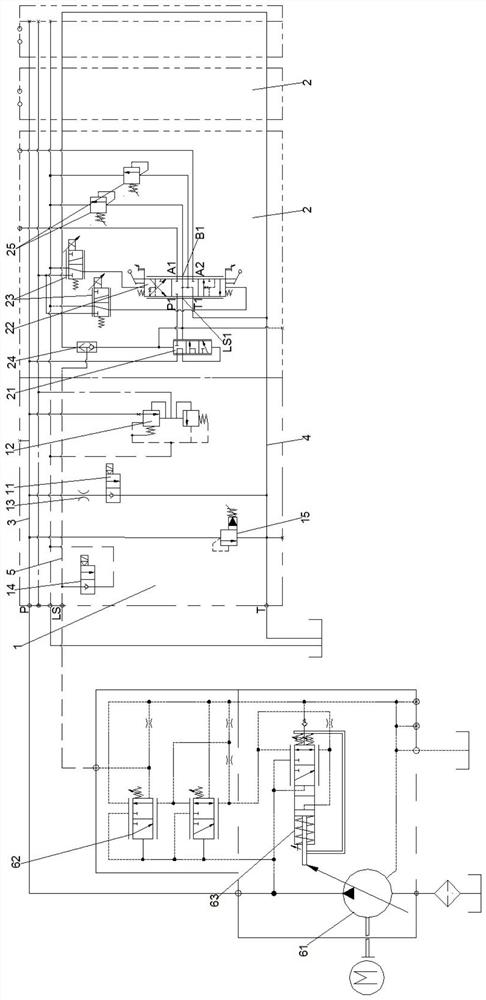

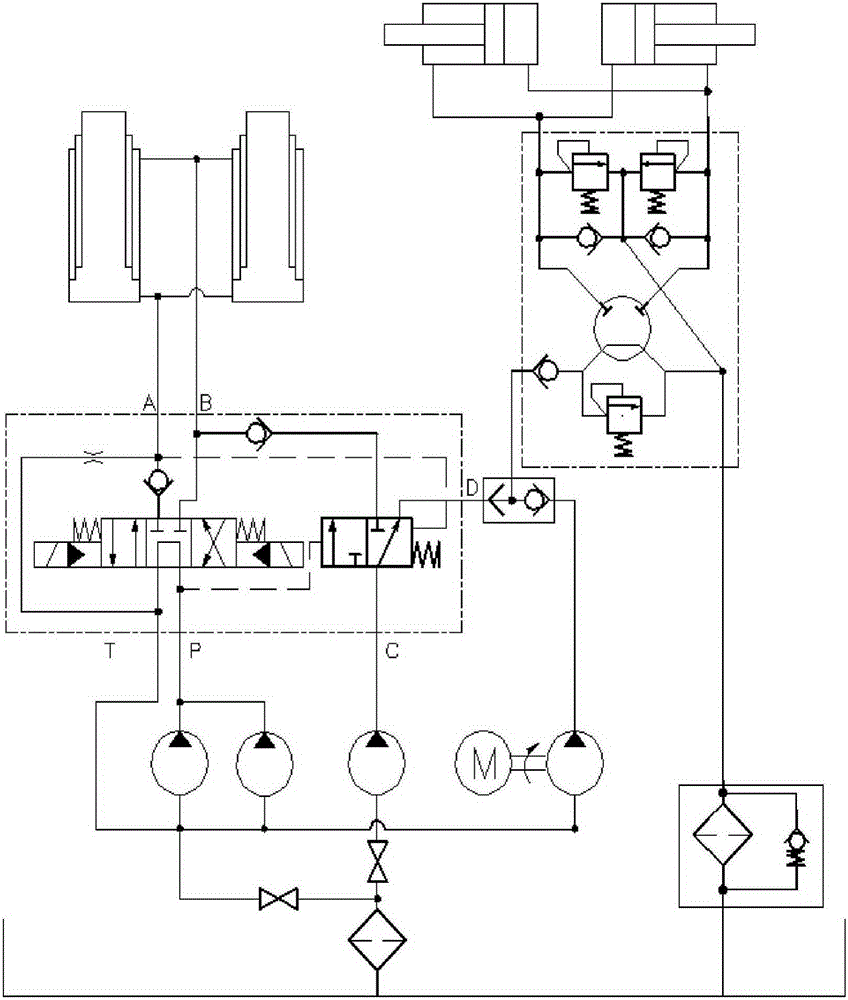

Load sensing heat dissipation braking variable system of loading machine

ActiveCN103171541ASuitable for useEasy to implementBrake coolingFluid braking transmissionLoad sensingConservation energy

The invention discloses a load sensing heat dissipation braking variable system of a loading machine. The load sensing heat dissipation braking variable system of the loading machine is characterized by mainly being composed of a variable displacement piston pump, a parking braking valve, a first energy accumulator, a second energy accumulator, a braking valve and a load sensing prefilling valve in an integral mode. A pressure oil port of the load sensing prefilling valve is connected with a pressure oil port of the variable displacement piston pump. Pressure oil is provided for the energy accumulators and working devices in a prefilling state. Pressure oil used for controlling a limit switch (LS) is output to control the variable displacement piston pump to provide flow required by a system. Priority of prefilling is maintained. A temperature signal of the heat dissipation system is converted into an electric signal to control an electric proportional pressure reducing valve in the load sensing prefilling valve, and the prefillig is prior. The variable displacement piston pump is a load sensing plunger pump comprising an LS control valve and a pressure stop valve and is capable of controlling a variable pump tilting tray to provide the flow required by the system. The load sensing heat dissipation braking variable system of the loading machine has the advantages of being easy to realize, saving in energy, and suitable for being used on loading machines of various tonnage.

Owner:GUANGXI LIUGONG MASCH CO LTD

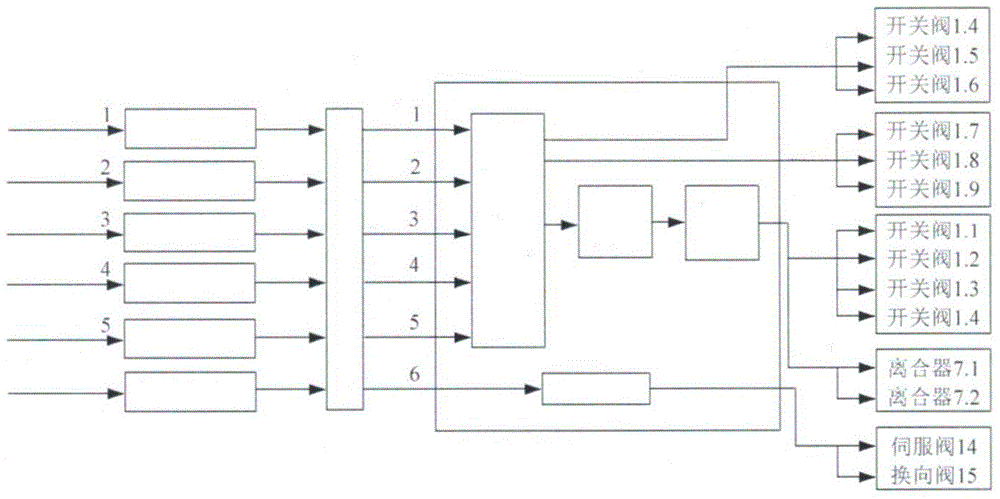

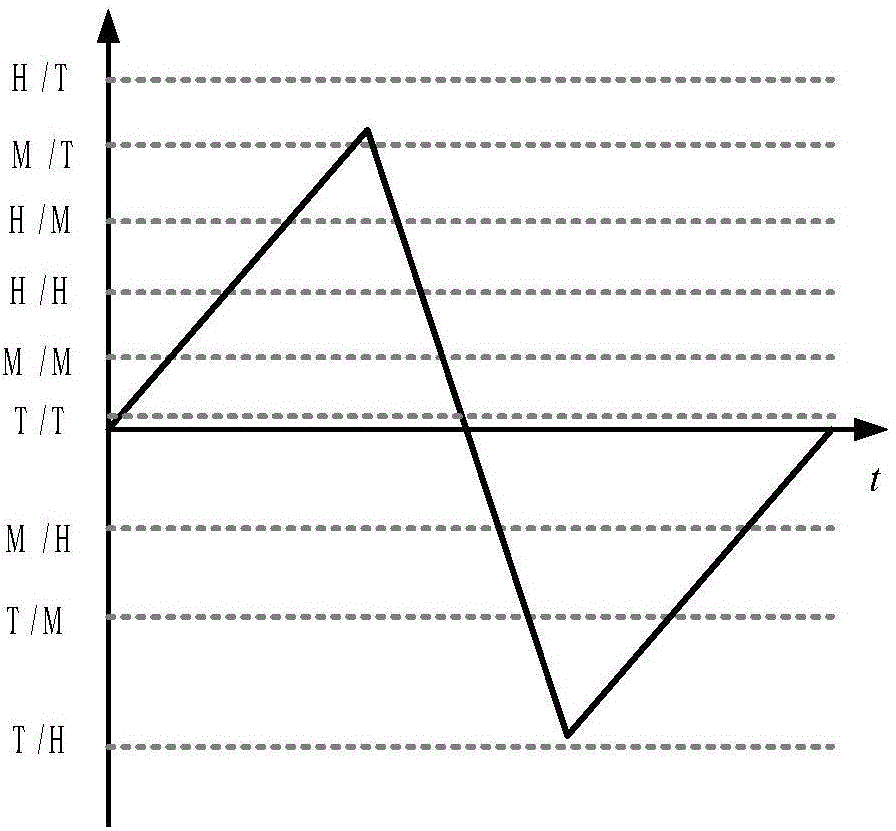

Energy-saving design method for variable-load servo control system

ActiveCN104929992AIncrease profitReduce overflow lossServomotorsServometer circuitsSystems designControl system

The invention relates to an energy-saving design method for a variable-load servo control system. According to a hydraulic system designed through the design method, fitting of matched load force is achieved through arbitrary combination of different pressure grades, and throttling losses of a valve port are reduced. Overall management of energy is achieved by means of an energy transmission unit and an energy storage unit. Control is conducted according to the working condition, so that regeneration and recycling of energy are achieved. The transmission efficiency of the system is improved on the premise that the control characteristic is guaranteed.

Owner:YANSHAN UNIV

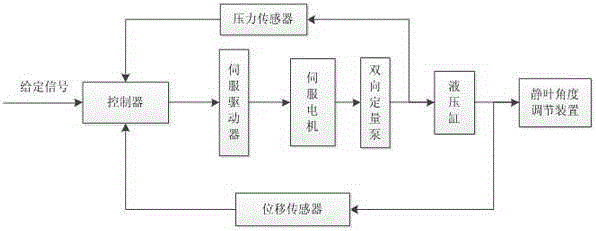

Novel adjusting system for stationary blades of axial flow fan

Owner:XIAN HUAKE AVIATION TECH

Quantitative and variable load sensitive confluence hydraulic system and loader

The invention relates to a hydraulic system to solve the problem that in an existing quantitative and variable hydraulic system, when a work hydraulic system acts, a steering variable pump cannot conduct load sensitive control on the work hydraulic system. A novel quantitative and variable load sensitive confluence hydraulic system and a loader are provided. The novel quantitative and variable load sensitive confluence hydraulic system comprises a steering hydraulic system and a work hydraulic system. The steering hydraulic system comprises a variable pump, a priority valve, a steering gear, a steering oil cylinder and the like. The work hydraulic system comprises a constant displacement pump, a distribution valve, a hydraulic execution piece, a pilot valve and the like. A first signal control valve and a second signal control valve connected to a bypass from a work pump to the execution piece are used for collecting load signals on a work oil way, the load signals of the work oil way are transmitted to the variable pump through a shuttle valve, and the load sensitive control over the work hydraulic system through the variable pump is achieved.

Owner:GUANGXI LIUGONG MASCH CO LTD

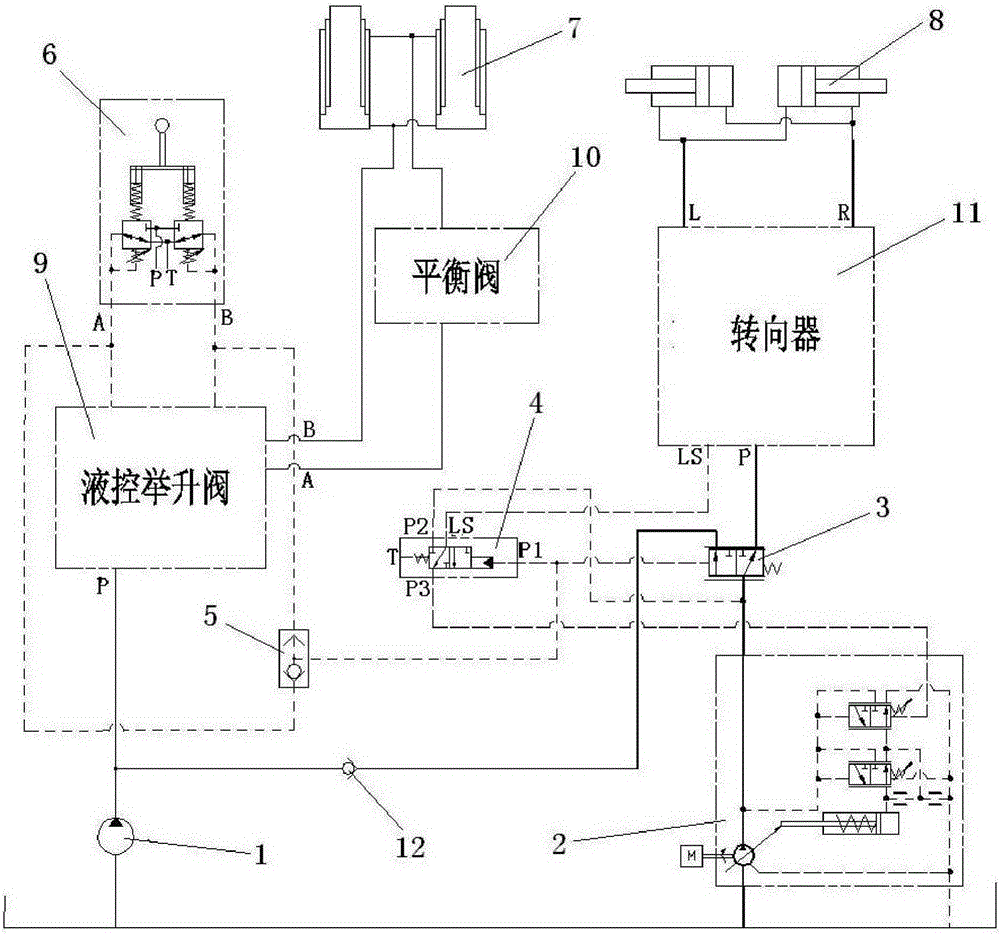

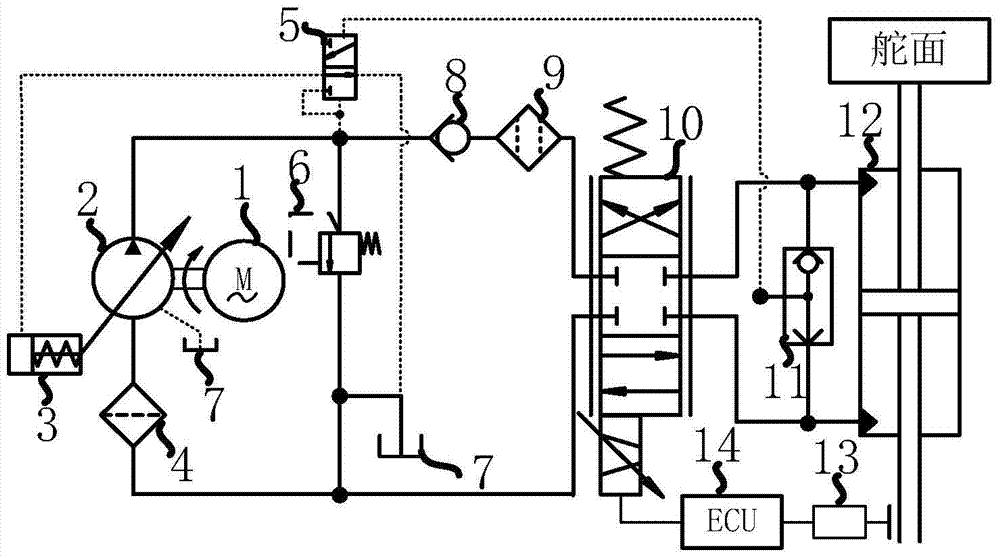

Hydraulic steering system for engineering machinery

ActiveCN104015798AAchieve the limitEliminate hydraulic shockFluid steeringVehicle frameControl manner

The invention discloses a hydraulic steering system for engineering machinery, and belongs to the technical field of hydraulic systems for the engineering machinery. The system comprises a steering pump and steering cylinders controlling the steering of the engineering machinery through a steering gear, wherein a priority valve is communicated with an oil way between the steering gear and the steering pump; a first hydraulic control reversing valve is communicated in series in an oil way between a third oil port of the steering gear and a second oil port of the priority valve; a shuttle valve, a second hydraulic control reversing valve and an engine-driven reversing valve are communicated in series in an oil way between the hydraulic control port of the first hydraulic control reversing valve and the first oil port of the steering pump; limiting blocks are respectively arranged on both sides, corresponding to the engine-driven reversing valve, of a vehicle frame of the engineering machinery. A hydraulic circuit control manner disclosed by the invention is simple and reliable. During the steering at a limit position of the cylinders, the system does not have a spill loss and hydraulic impact on the vehicle frame by the steering cylinders at the limit position is eliminated, so that energy is saved, rocking does not occur when the steering is finished, and the comfort of the whole vehicle is increased.

Owner:GUANGXI LIUGONG MASCH CO LTD

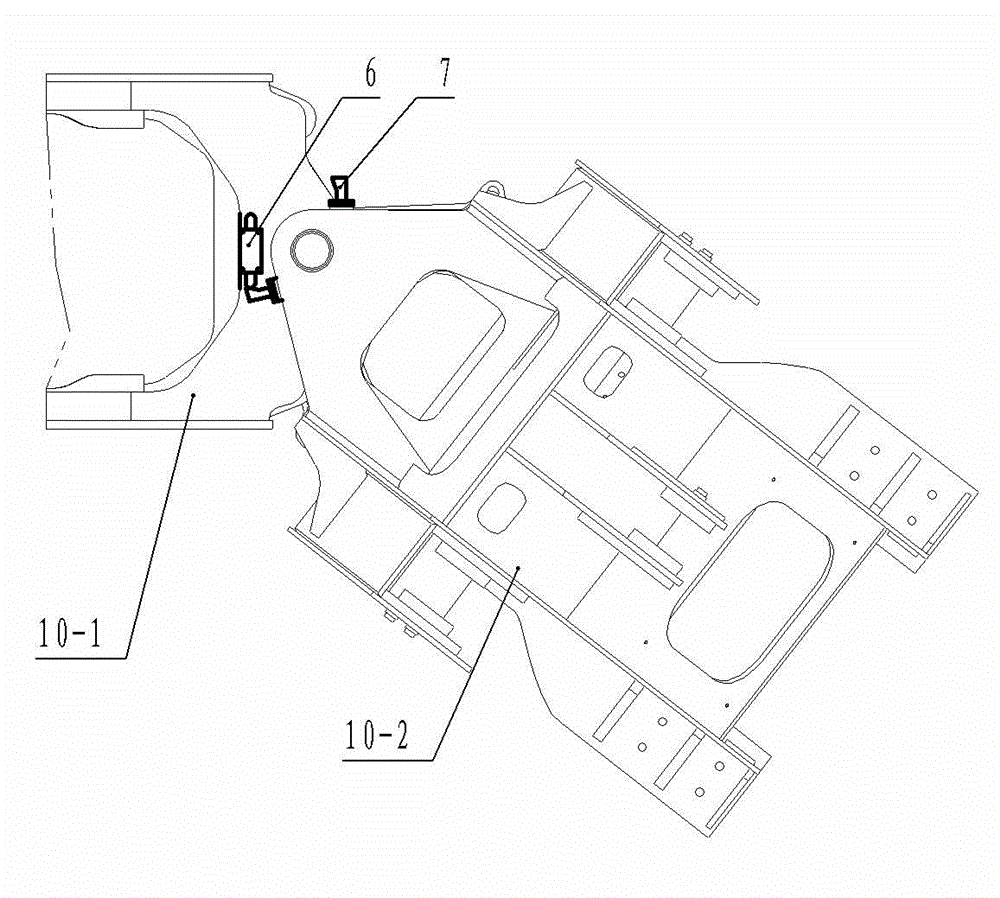

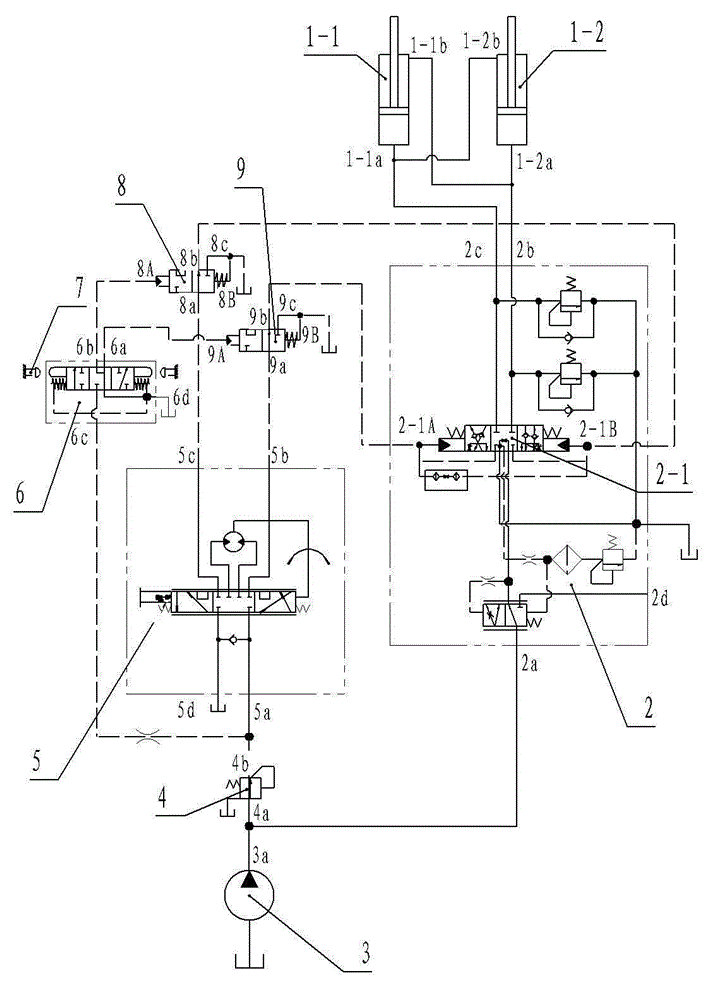

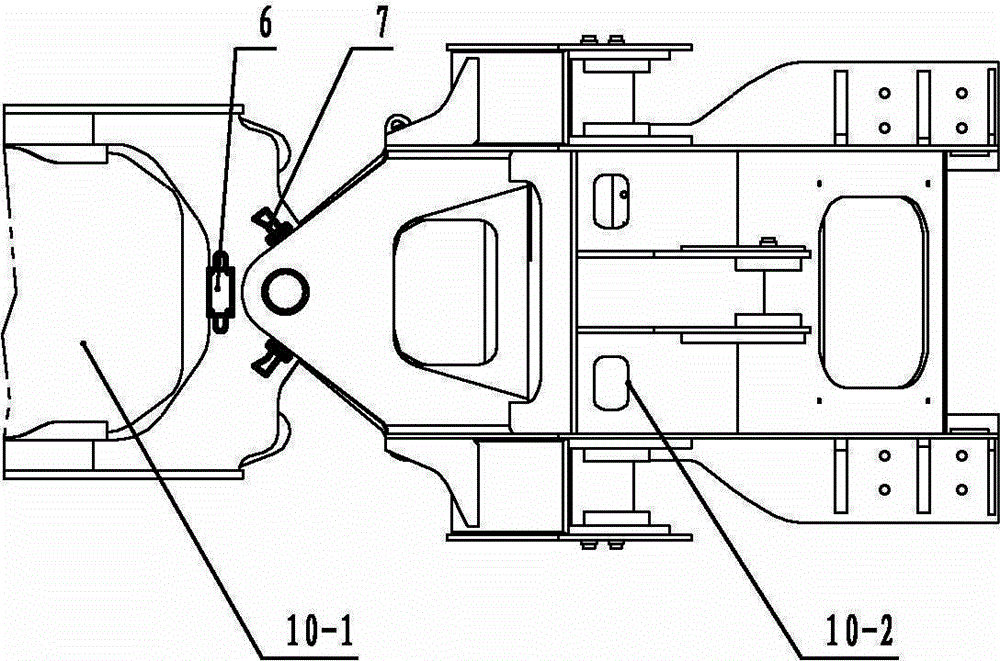

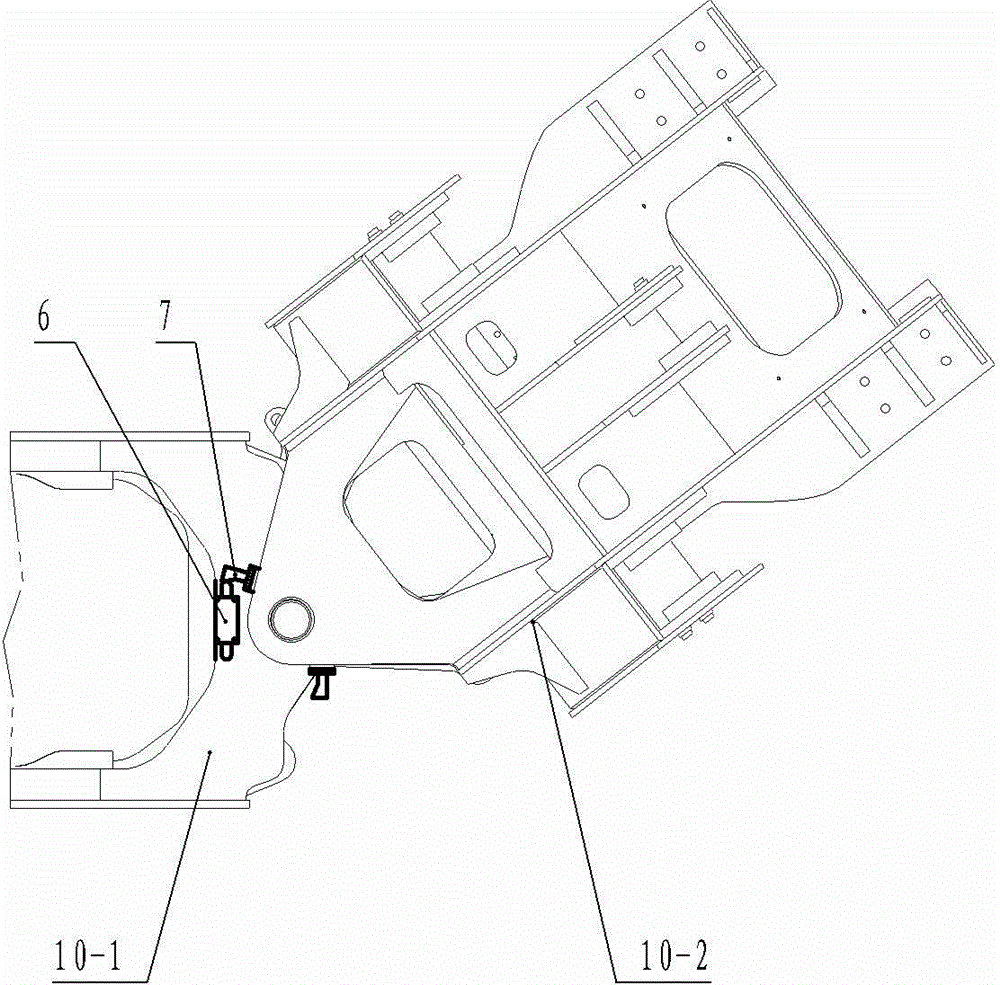

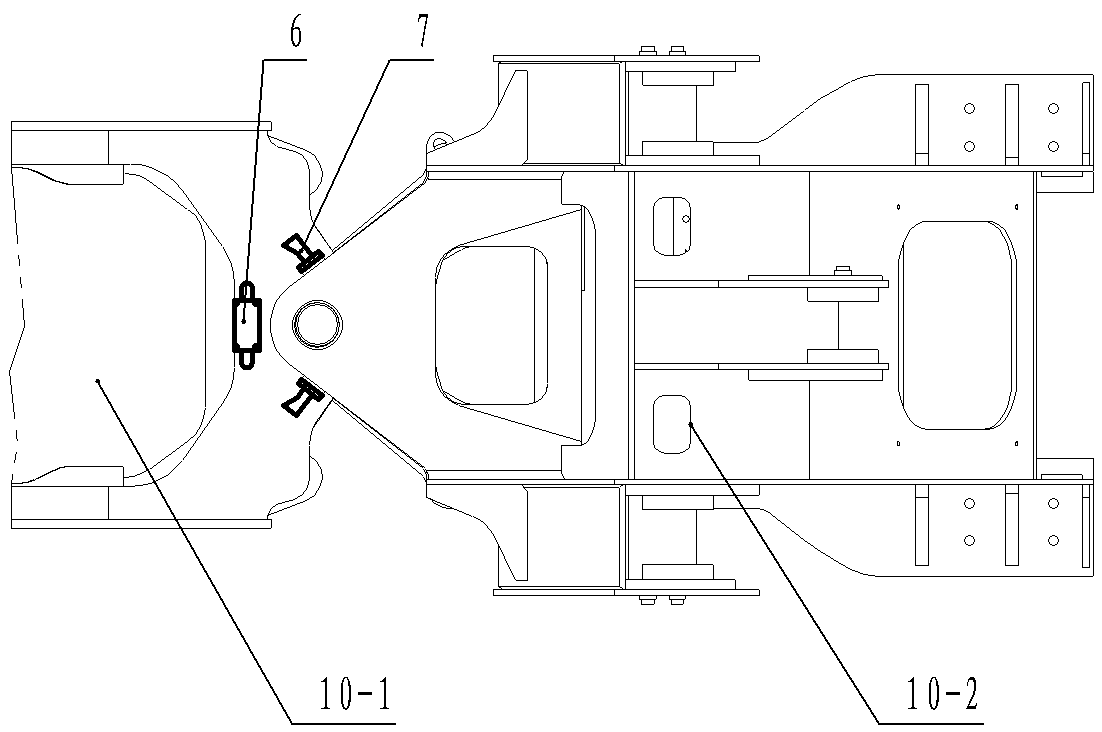

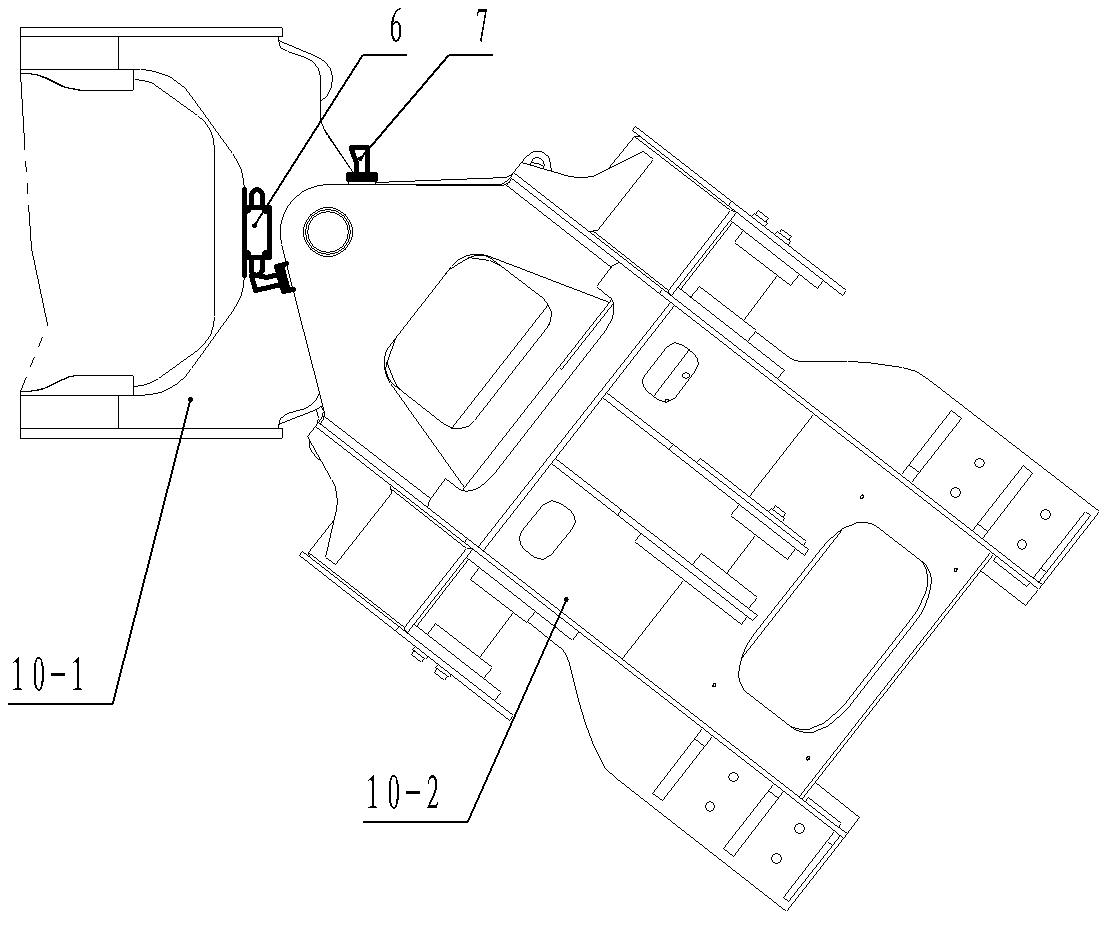

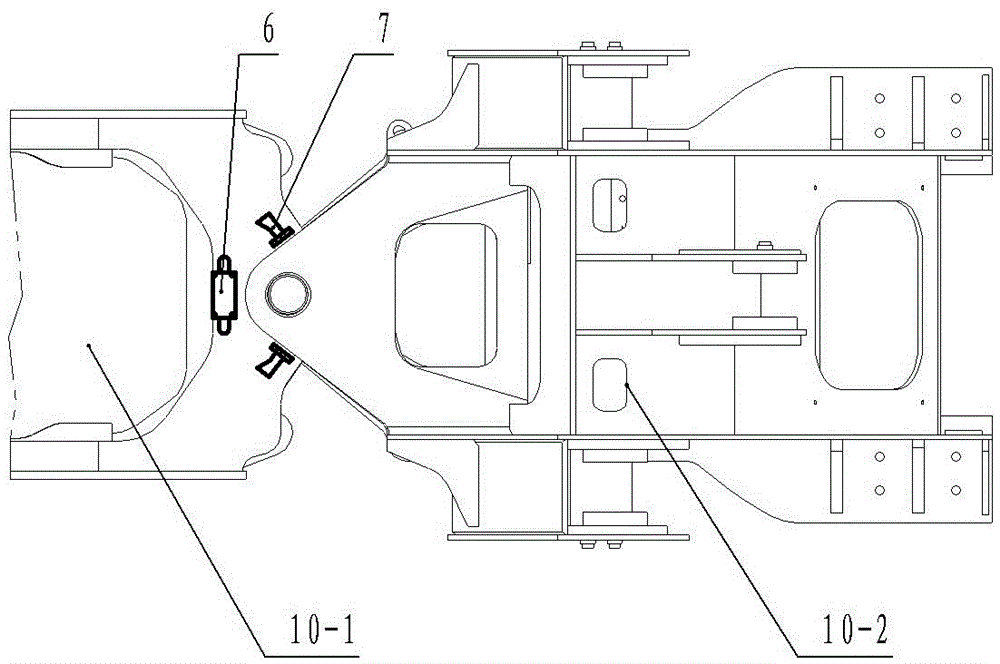

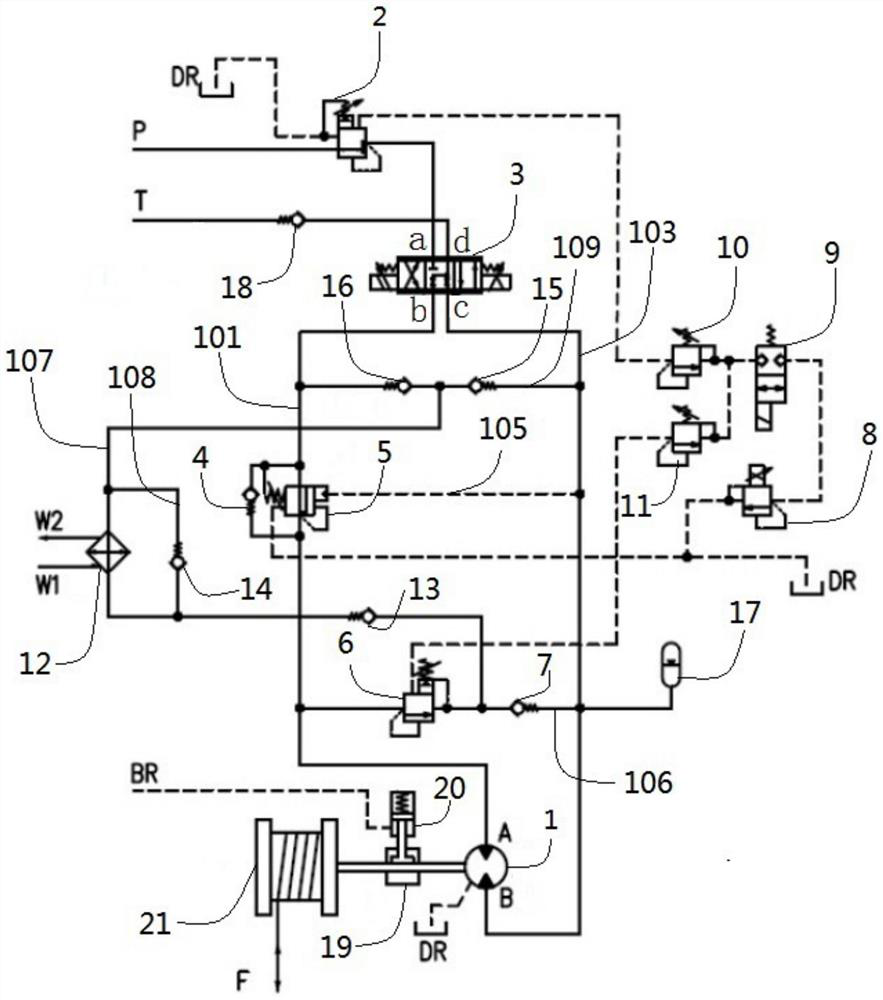

Hydraulic steering system of engineering machine

ActiveCN104029722AAchieve the limitEliminate hydraulic shockFluid steeringLoop controlControl engineering

The invention discloses a hydraulic steering system of an engineering machine and belongs to the technical field of hydraulic systems of engineering machines. The hydraulic steering system comprises a control part and a driving part, the control part comprises a steering gear, and the driving part comprises a steering oil cylinder and a steering pump. An amplification flow valve is serially communicated between the steering pump and the steering oil cylinder, a main valve spool controlling oil flow is arranged in the amplification flow valve, two liquid-control ports of the main valve spool are communicated with two oil outlets of the steering gear through liquid-control reversing valves, liquid-control ports of the liquid-control reversing valves are communicated with the steering pump through a maneuvering reversing valve and a pressure reducing valve. Limiters are arranged on a frame of the engineering machine and correspond to two sides of the maneuvering reversing valve. The hydraulic steering system is simple and reliable in hydraulic loop control manner, no overflow loss of the hydraulic steering system is caused when the engineering machine steers at the limit position of the oil cylinder, hydraulic impact to the frame from the limit position of the oil cylinder during steering is eliminated, energy is saved while shaking after steering is avoided, and comfortableness of the integral engineering machine is improved.

Owner:GUANGXI LIUGONG MASCH CO LTD

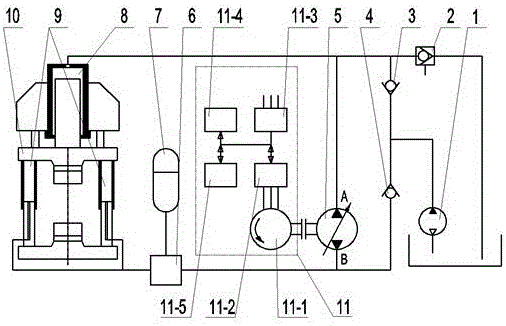

Hydraulic press pump controlled hydraulic system with renewable power generation

InactiveCN105782149AQuick responseHigh control precisionServomotorsFluid-pressure actuator componentsFailure rateCoupling

The invention relates to a hydraulic press pump controlled hydraulic system with renewable power generation and aims at solving the problems of the traditional hydraulic press pump controlled hydraulic system of high power consumption, strong system impact vibration, high failure rate, low production efficiency and low energy utilization ratio without full utilization of compression energy. The hydraulic press pump controlled hydraulic system with renewable power generation is characterized in that a reversible variable axial plunger pump is installed between a main working cylinder and return cylinders; a liquid supply pump is connected with the main working cylinder through a first check valve and the reversible variable axial plunger pump through a second check valve and directly controls the main working cylinder and the return cylinders to drive a moving beam of a hydraulic press to move through the reversible variable axial plunger pump; and a regenerative power generation system is connected to the reversible variable axial plunger pump through a coupler. The hydraulic press pump controlled hydraulic system has the beneficial effects that the response speed of the system is rapid, the control accuracy is high, no impact vibration occurs in the pressure and charge relieving process of the main working cylinder, and thus impact vibration of the system is eliminated; and in addition, the compression energy of hydraulic oil of the hydraulic press can be converted to electric energy, or stored for recycling or directly supplied to other electric servo motors, so that the energy saving effect is remarkable.

Owner:沈阳重机重矿机械设备制造有限公司

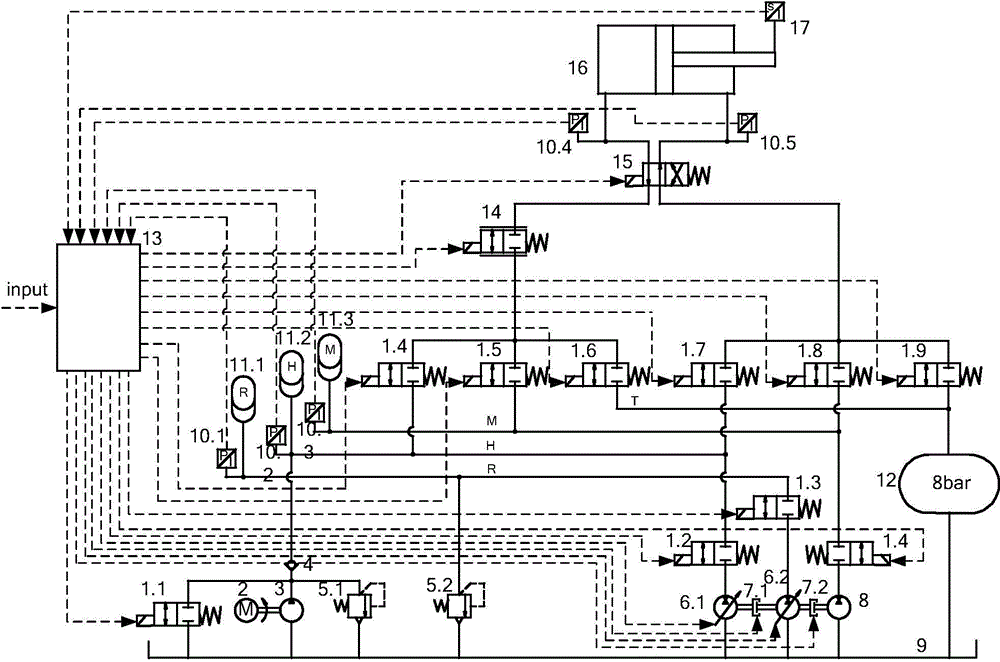

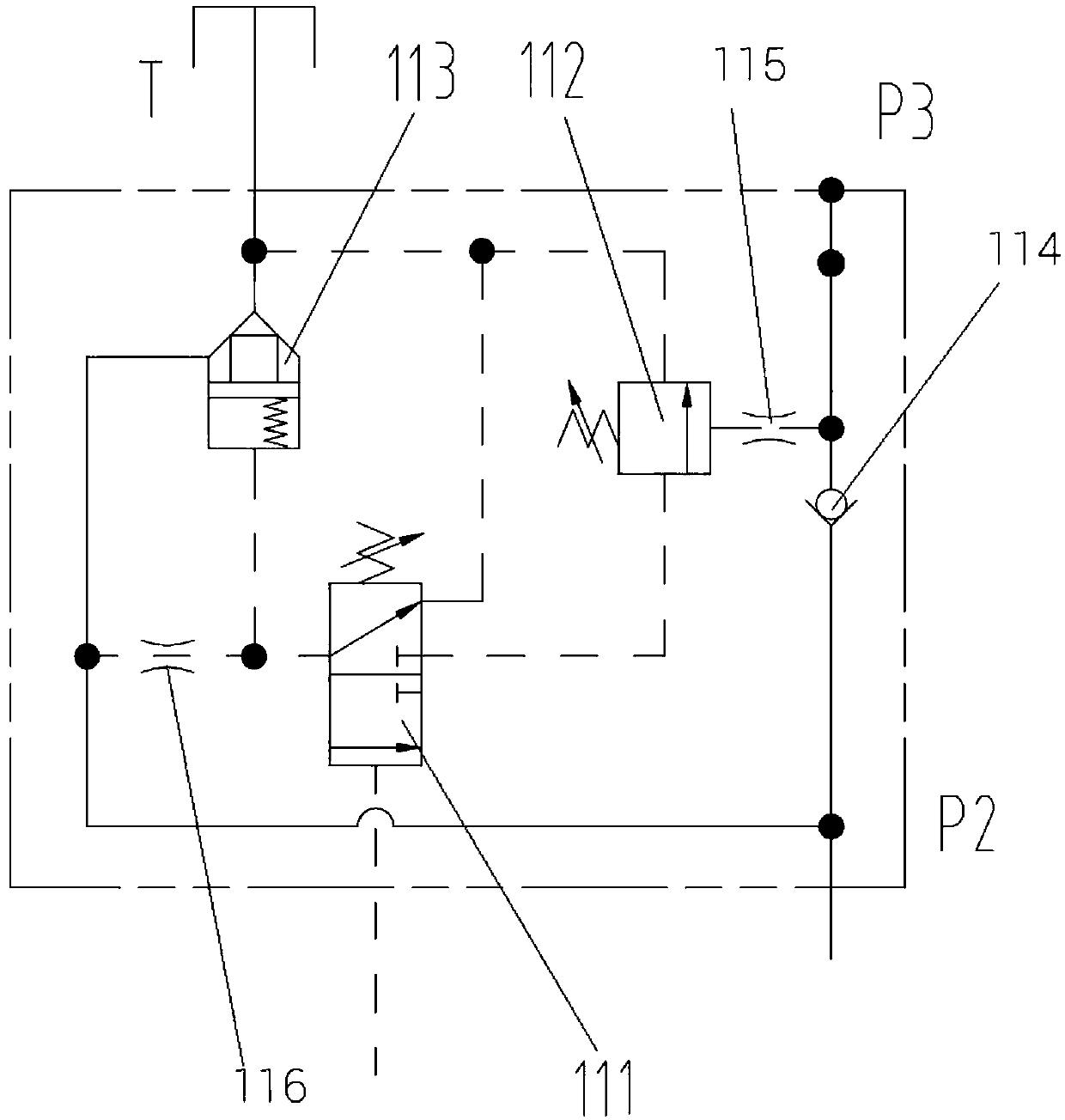

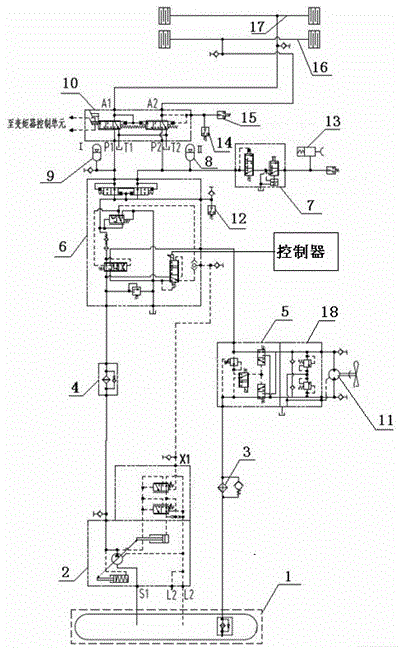

Contiuously variable transmission electro-hydraulic control system based on pilot control of high-speed switch valves

ActiveCN110425276AImprove work efficiencyIncrease the speed ratioGearing controlHydraulic cylinderDrive wheel

The invention discloses a contiuously variable transmission electro-hydraulic control system based on the pilot control of high-speed switch valves. The system involves a speed ratio control hydraulicloop, a clamping force control hydraulic loop, an ECU electric control unit, a quantifying pump and a pilot pump; the speed ratio control hydraulic loop comprises a first HSV high-speed switch valve,a second HSV high-speed switch valve, a first cartridge valve, a second cartridge valve and a driving wheel hydraulic cylinder; the clamping force control hydraulic loop comprises a third HSV high-speed switch valve, a fourth HSV high-speed switch valve, a third cartridge valve, a fourth cartridge valve and a driven wheel hydraulic cylinder; and the ECU electric control unit is connected with thefirst HSV high-speed switch valve, the second HSV high-speed switch valve, the third HSV high-speed switch valve and the fourth HSV high-speed switch valve, and can be used for controlling the quantifying pump and the pilot pump to be opened. According to the system, the structure is simple, the cost is low, the cartridge valves are adopted by taking the high-speed switch valves as pilot valves,so that the high-pressure and large-flow working performance is easily realized, and the working efficiency of the system is improved.

Owner:XIANGTAN UNIV

Fixed-displacement and variable-displacement hydraulic system of loading machine

The invention relates to a hydraulic system, solves the problem that variable-displacement steering pumps cannot perform variable-displacement control on working hydraulic systems when the working hydraulic systems in existing fixed-displacement and variable-displacement hydraulic systems act, and provides a fixed-displacement and variable-displacement hydraulic system of a loading machine. The fixed-displacement and variable-displacement hydraulic system comprises a steering hydraulic system and a working hydraulic system; the steering hydraulic system comprises a variable-displacement steering pump, a pressure-gradient control valve, a steering gear, a steering oil cylinder and the like; the working hydraulic system comprises a fixed-displacement pump, a distribution valve, a hydraulic actuator, a pilot valve, a shuttle valve group and the like; when a pilot handle acts, a load signal acquired from the distribution valve is transmitted to a load simulating valve on a bypass from a steering pump to the distribution valve, the differential pressure of the loading pressure acquired by the pump and the distribution valve is amplified by the aid of the difference between acting areasof two differential pressure of the load simulating valve, the amplified differential pressure finally acts on a flow control valve of the steering pump, and variable-displacement control on the working hydraulic system by the variable-displacement steering pump is realized.

Owner:GUANGXI LIUGONG MASCH CO LTD

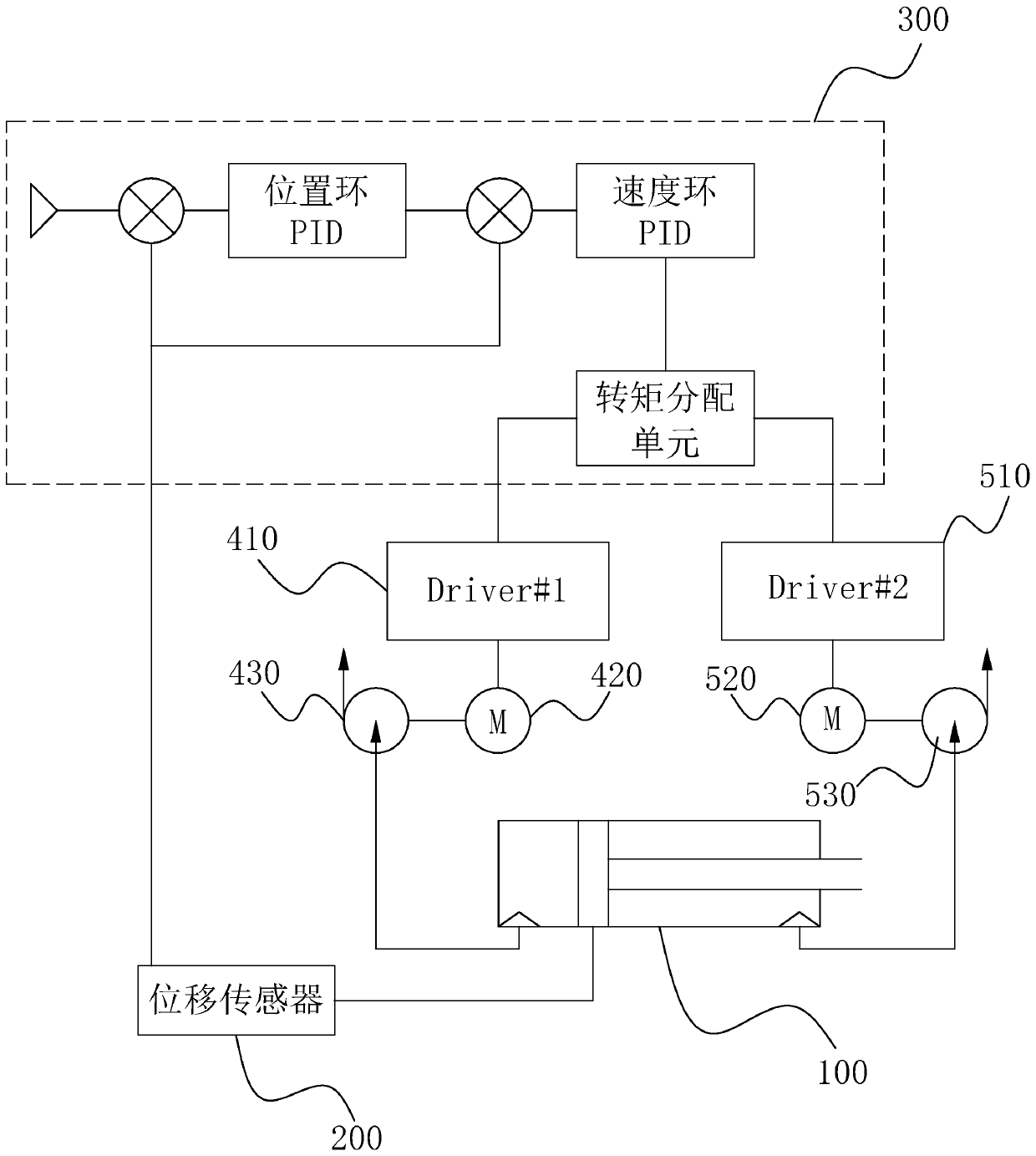

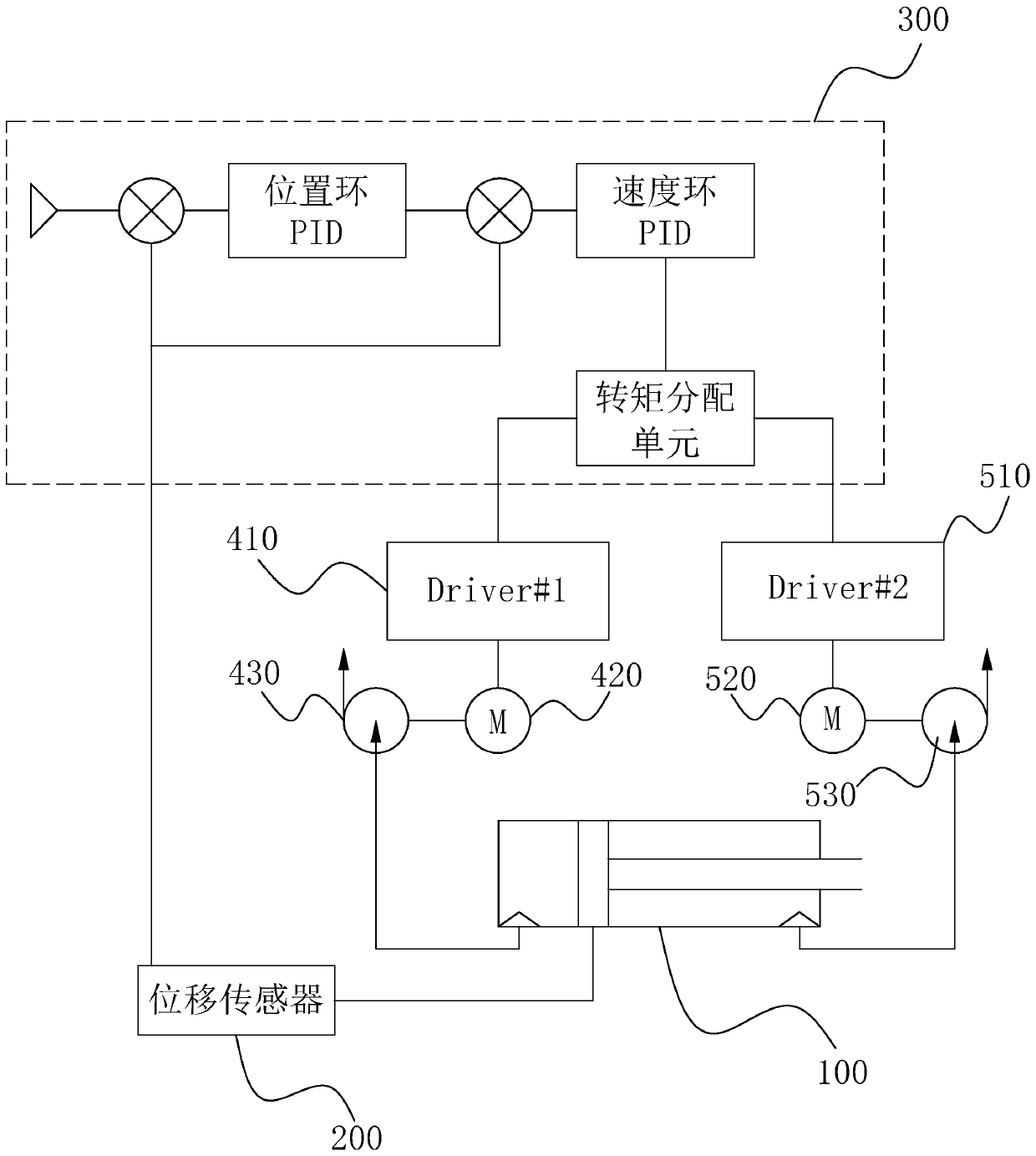

Hydraulic cylinder position control system and control method based on bidirectional pressure inputting adjustment

PendingCN109915442AImprove controllabilityImprove responsivenessFluid-pressure actuator componentsHydraulic cylinderClosed loop

The invention discloses a hydraulic cylinder position control system and control method based on bidirectional pressure inputting adjustment. The system involves a hydraulic cylinder, two symmetrically-arranged servo driving devices, a displacement sensor and a motion control unit used for distributing output, wherein the two servo driving devices are connected to an inlet and an outlet of the hydraulic cylinder respectively, the displacement sensor is connected with a piston of the hydraulic cylinder to obtain displacement information, the displacement sensor is connected with the motion control unit, and the motion control unit is connected with the two servo driving devices to form a closed-loop control loop. According to the control system and the control method, the responsiveness isvery high, the speed control range is wide, the controllability of the piston is good, the position can be bidirectionally adjusted at any speed and load, position deviation is eliminated, regenerative energy recovery can be carried out through direct current parallel connection, and energy is further saved.

Owner:江门市蒙德电气股份有限公司

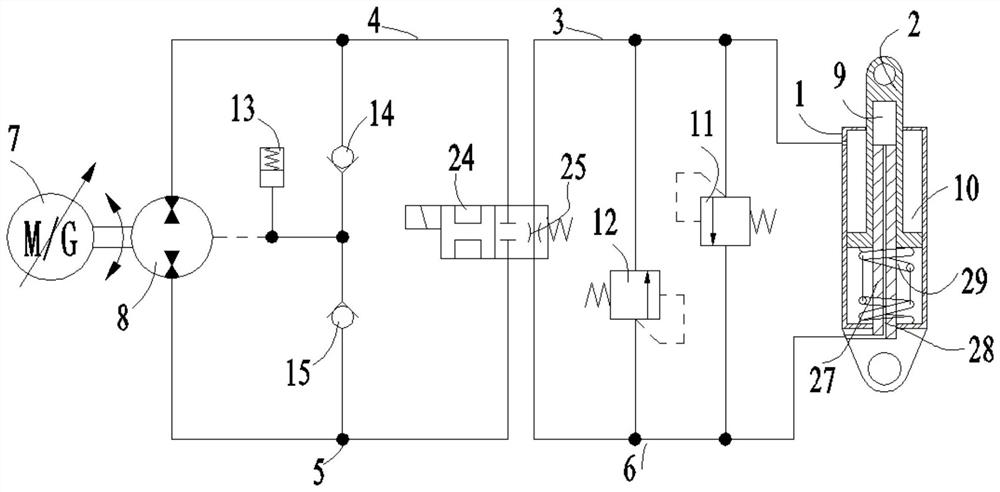

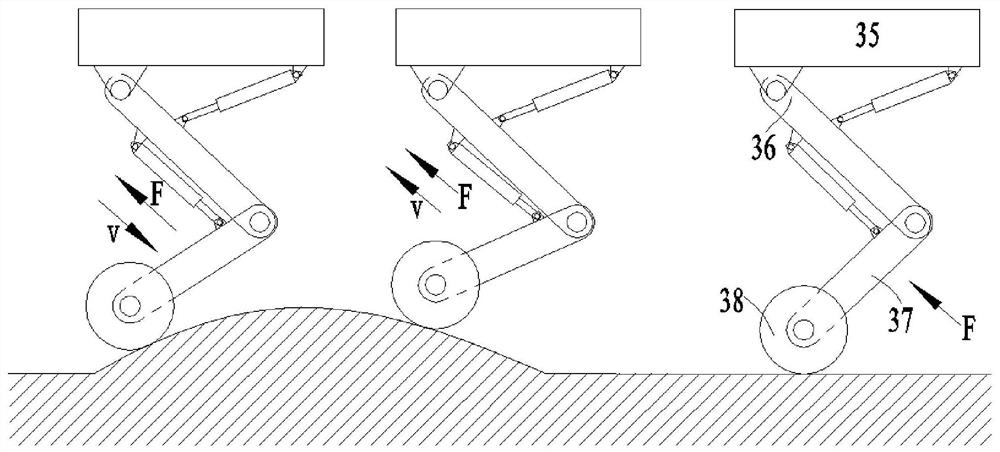

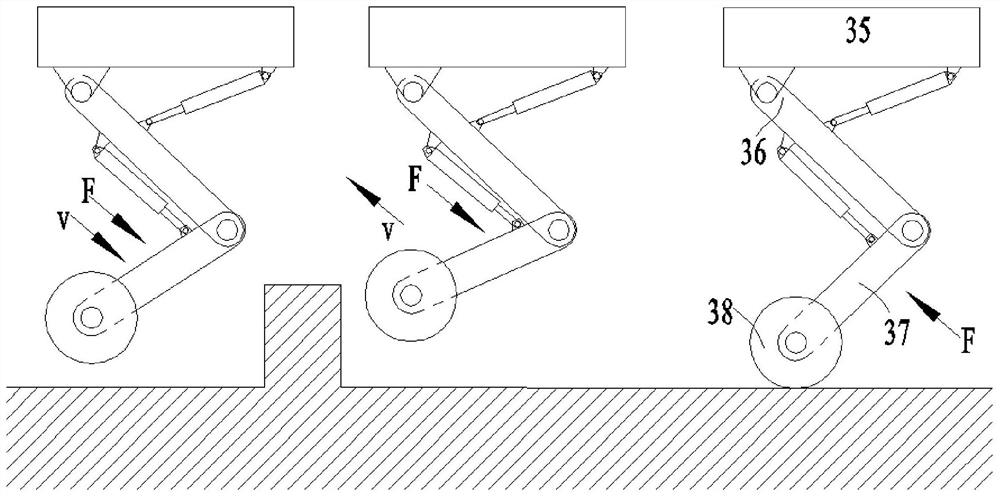

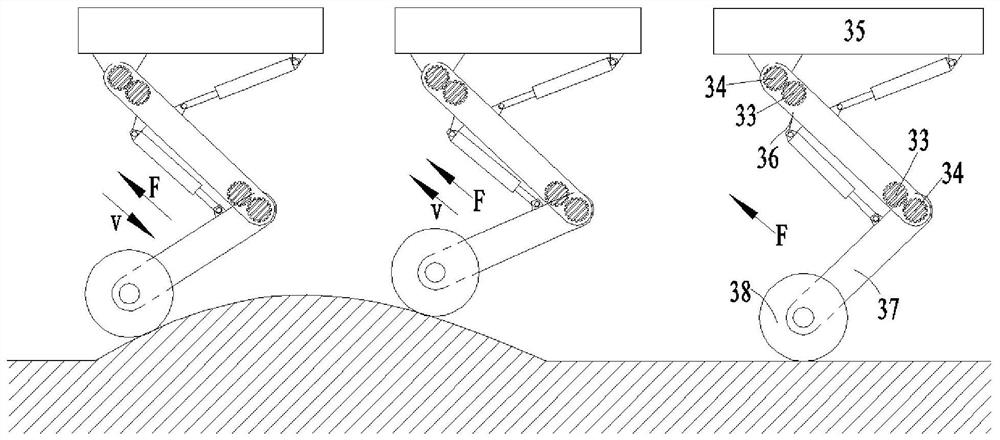

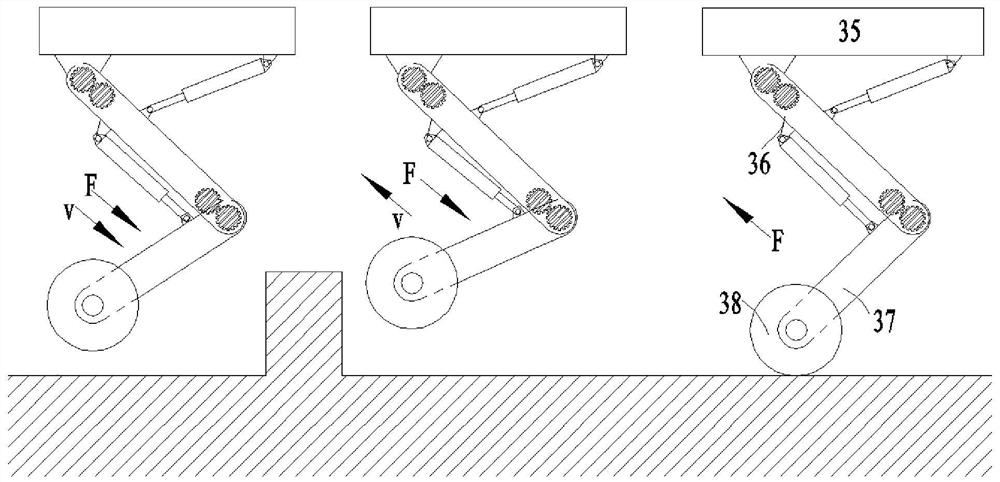

Wheel-legged robot and leg joint driving device thereof

PendingCN112460085ASolution to short lifeImprove transfer efficiencyServomotor componentsServomotorsHydraulic cylinderControl system

The invention discloses a wheel-legged robot and a leg joint driving device thereof, and belongs to the technical field of wheel-legged robots. The wheel-legged robot comprises a hydraulic control system, wherein the hydraulic control system comprises a hydraulic cylinder, a piston rod, a main oil path, a secondary oil path, a servo motor and a hydraulic pump; a bearing cavity and a non-bearing cavity are formed in the hydraulic cylinder; the piston rod is used for separating the bearing cavity from the non-bearing cavity; the servo motor is used for driving the hydraulic pump; the non-bearingcavity, the main oil path, the hydraulic pump, the secondary oil path and the bearing cavity communicate with one another in sequence; and the elongation of the piston rod relative to the hydraulic cylinder is changed along with change of the capacity of hydraulic oil in the bearing cavity and the non-bearing cavity. According to the wheel-legged robot and the leg joint driving device thereof, overflow loss and throttling loss are avoided, the system power is saved, the transmission efficiency of the hydraulic system is high, the energy utilization rate is high, the buffering performance is good, and the service life is long.

Owner:北京理工大学重庆创新中心 +1

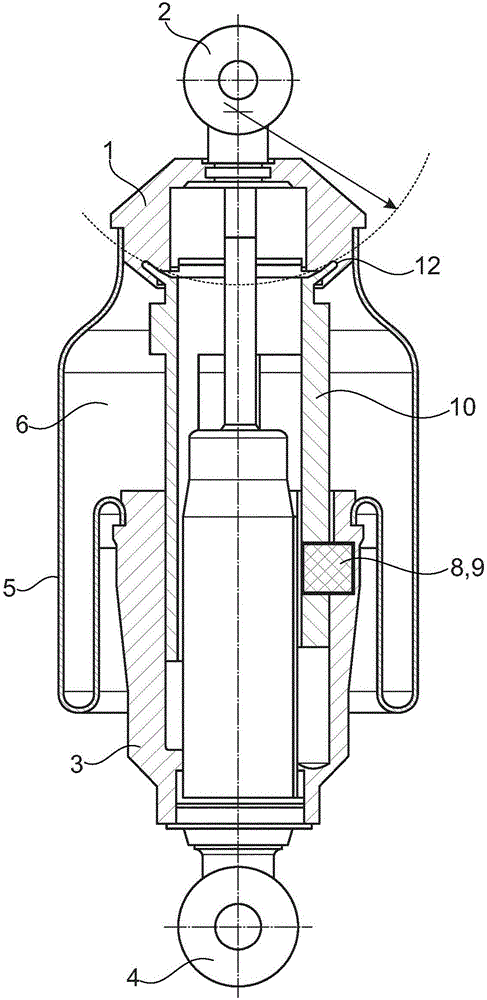

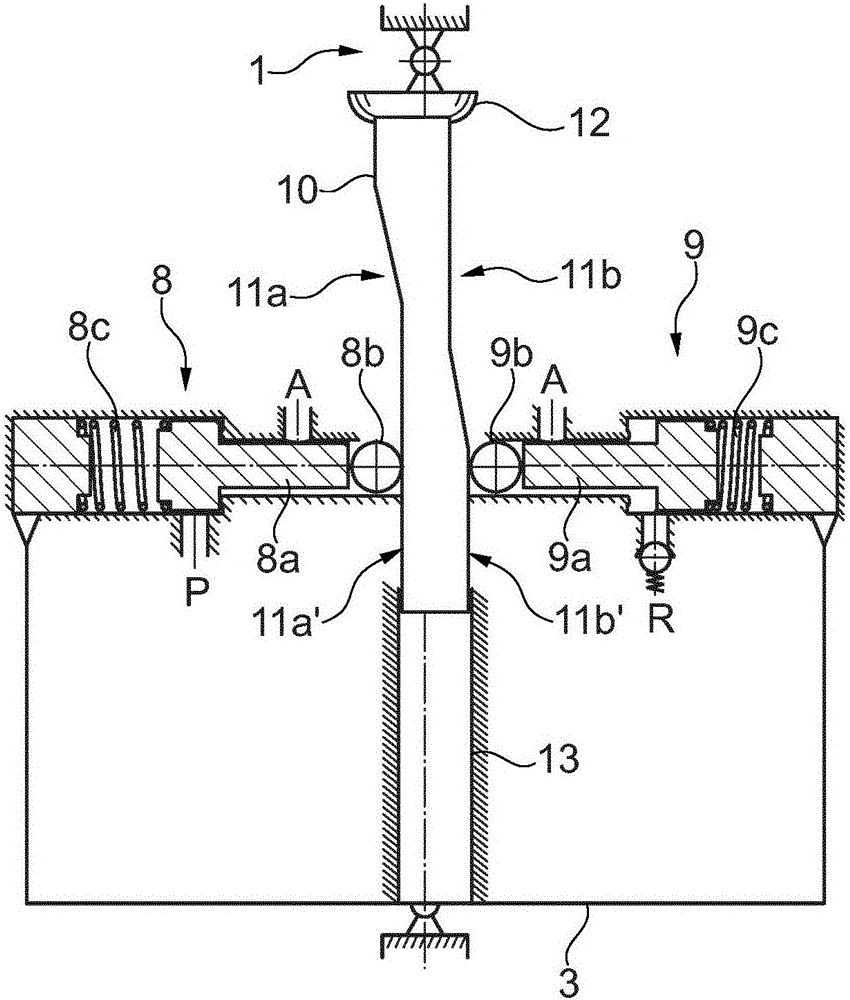

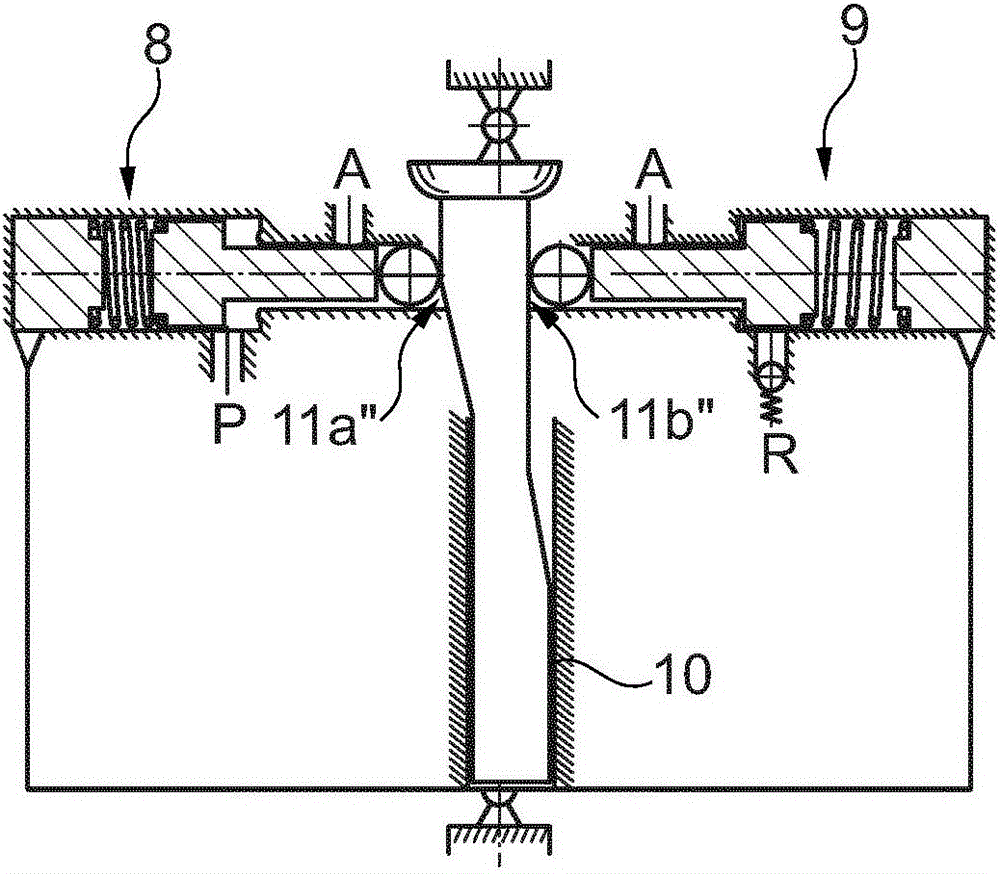

Air spring assembly having integrated control valve and rod-shaped actuating element

ActiveCN105960343ANo overflow lossLow cost to achieveSpringsResilient suspensionsExhaust valveAir spring

The invention relates to an air spring assembly, comprising an integrated control valve assembly for admitting compressed air into a spring pressure chamber (6) formed between an outer tube (1), a rolling tube (3), and an air spring bellows (5) that connects these components, wherein the control valve assembly consists of an individual air inlet valve (8) and an individual air outlet valve (9), which can be actuated by likewise integrated mechanical actuating elements in accordance with the air spring stroke position in order to admit air into or let air out of the spring pressure chamber (6), wherein the air inlet valve (8) is arranged opposite the air outlet valve (9) with actuating tappets (8a; 9a) facing each other, wherein the mechanical actuating elements that act on the actuating tappets while lying therebetween comprise a switching rod (10) attached to the outer tube (1) or rolling tube (3) at one end, the sliding tracks (11a, 11b) of which switching rod, which are opposite each other and which are each associated with one of the actuating tappets (8a, 8b), act on the actuating tappets (8a; 8b) in order to actuate the valves in dependence on the stroke position.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

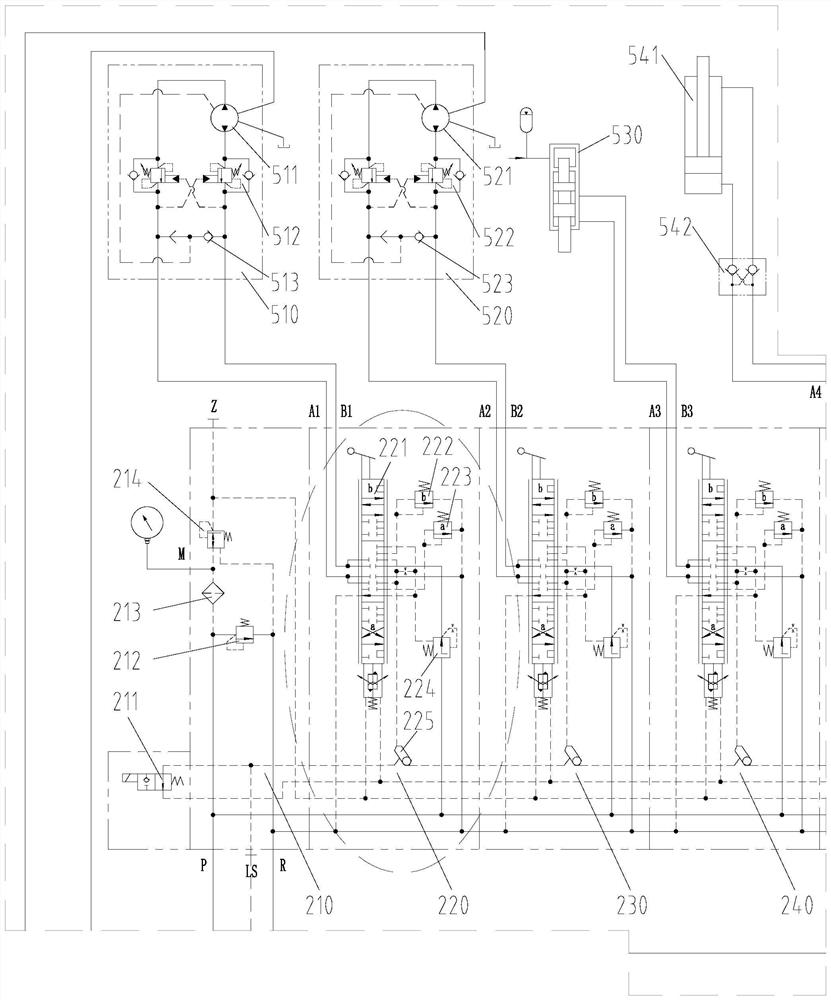

Load-sensitive multi-way valve, boom hydraulic control system and concrete pump truck

PendingCN113007157AGuaranteed service lifeGood flow stabilityServomotor componentsServomotorsHydraulic controlControl system

The invention relates to a multi-way valve, and discloses a load-sensitive multi-way valve, a boom hydraulic control system and a concrete pump truck. The load-sensitive multi-way valve comprises an oil inlet unit, at least one working unit, a main oil inlet path for communicating an oil inlet of the oil inlet unit with oil inlets of the working units, a main oil return path for communicating with an oil return port of the oil inlet unit and oil return ports of the working units, and a load feedback oil path for communicating with a feedback oil port of the oil inlet unit and feedback oil ports of the working units, wherein the oil inlet unit comprises a flushing mechanism, the flushing mechanism is connected between the main oil inlet path and the main oil return path, and the flow pumped into the oil inlet unit can be unloaded when the system is in a neutral-position standby state. The load-sensitive multi-way valve not only can prevent the temperature of local oil at the outlet of a variable pump and in the shell from being too high, but also is good in flow stability and free of excessive high-pressure oil overflow loss.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

Wheeled leg robot and driving method thereof

PendingCN112550512AImprove transfer efficiencyImprove energy utilizationVehiclesHydraulic controlControl system

The invention discloses a wheeled leg robot and a driving method thereof, and belongs to the technical field of wheeled leg robots, the wheeled leg robot comprises a vehicle body, thighs, shanks, wheels and two hydraulic control systems; one end of the thigh is hinged with the vehicle body, and the other end is hinged with one end of the shank; wheels are arranged at the other ends of the shanks;the two hydraulic control systems control the included angle between the vehicle body and the thigh and the included angle between the thigh and the shank respectively. The hydraulic control system comprises a hydraulic cylinder and a piston rod; a bearing cavity, a non-bearing cavity and a spring are arranged in the hydraulic cylinder; the piston rod divides the bearing cavity and the non-bearingcavity; and the spring is used for enabling the rod part of the piston rod to tend to extend out of the hydraulic cylinder. According to the wheeled leg robot and the driving method thereof, overflowloss and throttling loss are avoided, the system power is saved, the transmission efficiency of a hydraulic system is high, the energy utilization rate is high, the buffering performance is good, andthe service life is long.

Owner:北京理工大学重庆创新中心 +1

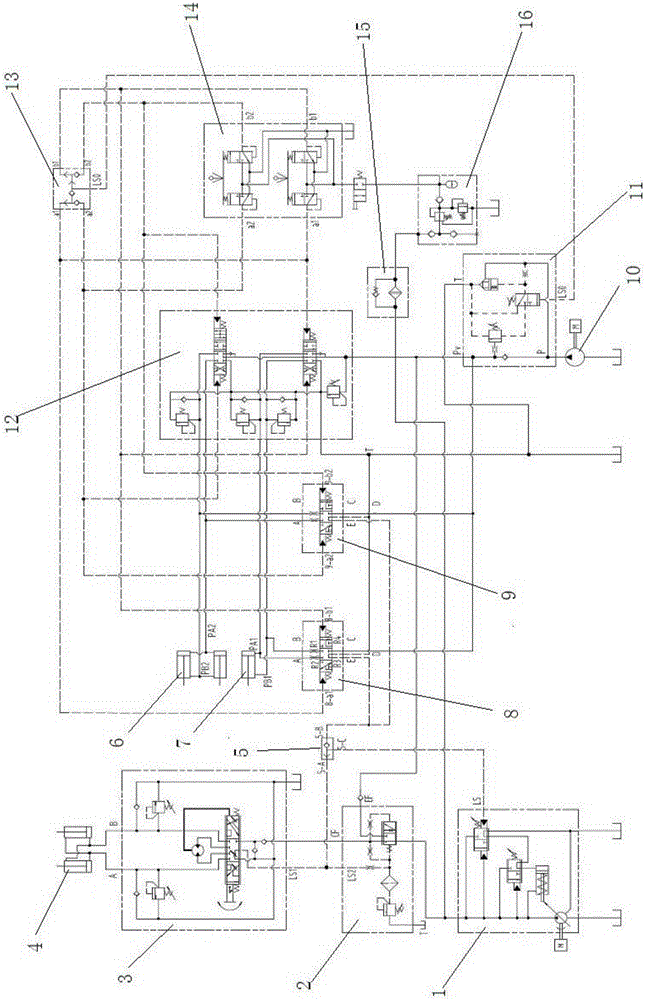

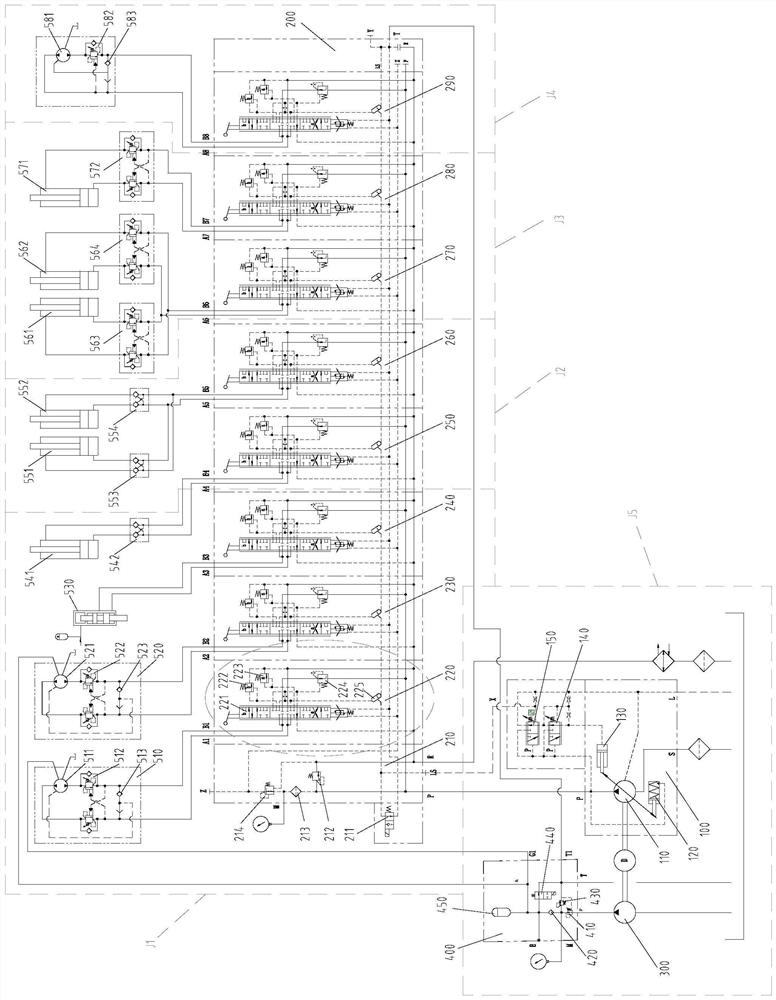

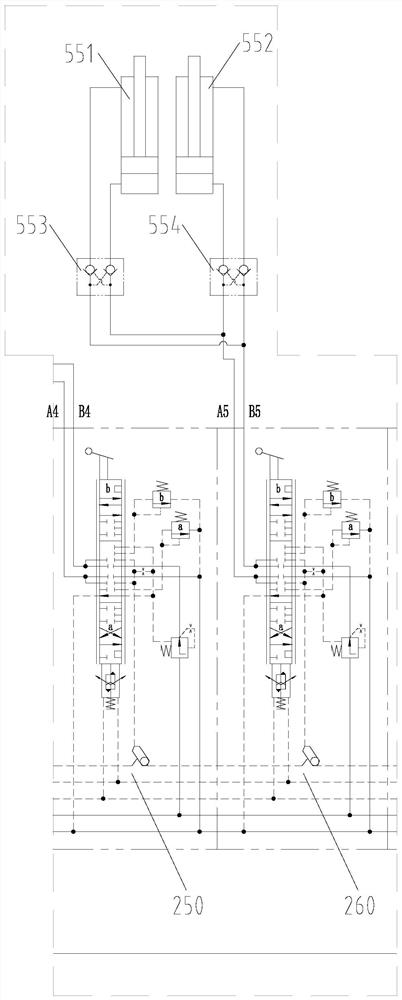

Load sensitive control hydraulic system of pile driver

PendingCN113266612APrecise control of movement speedImprove work efficiencyServomotor componentsServomotorsLow speedControl theory

The invention discloses a load sensitive control hydraulic system of a pile driver, which comprises a load sensitive multi-way valve, a load sensitive variable pump, a walking motor, a hydraulic hammer, a left oil cylinder, a right oil cylinder, a front oil cylinder, a rear oil cylinder, a variable amplitude oil cylinder, a lifting oil cylinder, a lifting motor, a pilot pump, a pilot valve set and the like, wherein the load sensitive variable pump is connected with the load sensitive multi-way valve; the load sensitive valve controls execution elements such as the walking motor, the hydraulic hammer, the left oil cylinder, the right oil cylinder, the front oil cylinder, the rear oil cylinder, the variable amplitude oil cylinder, the lifting oil cylinder and the lifting motor, and the pilot pump and the pilot valve set control high and low speed switching of the walking motor. The load sensitive control hydraulic system is suitable for the hydraulic system of the road guardrail pile driver, can obviously reduce the power loss of the road guardrail pile driver and improve the work efficiency.

Owner:XUZHOU HENGXING JINQIAO MACHINERY TECH

Wheeled leg robot and driving method thereof

ActiveCN112550513AImprove energy utilizationSolution to short lifeVehiclesHydraulic cylinderGear wheel

The invention discloses a wheeled leg robot and a driving method thereof, and belongs to the technical field of wheeled leg robots, the wheeled leg robot comprises a vehicle body, thighs, shanks, wheels and two hydraulic control systems; the hydraulic control system comprises a hydraulic cylinder, a piston rod and a motor gear control system; a bearing cavity and a non-bearing cavity are formed inthe hydraulic cylinder; the piston rod separates the bearing cavity from the non-bearing cavity; a hydraulic control system controls the extension of the piston rod relative to the hydraulic cylinderor controls the included angle between the vehicle body and the thigh through a motor gear control system; and the other hydraulic control system controls the extension of the piston rod relative tothe hydraulic cylinder or controls the included angle between the thigh and the shank through a motor gear control system. According to the wheeled leg robot and the driving method thereof, overflow loss and throttling loss are avoided, the system power is saved, the transmission efficiency of a hydraulic system is high, the energy utilization rate is high, the buffering performance is good, and the service life is long.

Owner:北京理工大学重庆创新中心 +1

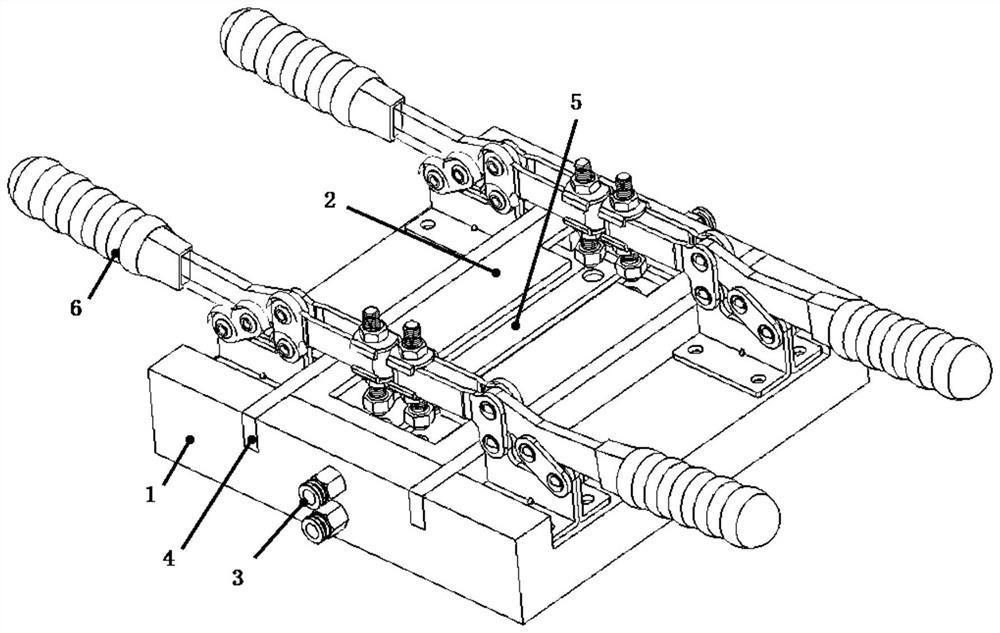

Laser welding clamp with double-sided inert gas protection

PendingCN114473341AWon't overflowNo overflow lossWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to a laser welding clamp with double-sided inert gas protection. Comprising a ventilation base, an objective table, a ventilation nozzle, a baffle, a pressing block and a clamp. An objective table mounting groove is formed in the middle of the ventilation base, and a protective gas groove communicating with the objective table mounting groove is formed in the lower side of the middle of the objective table mounting groove; the objective table comprises an upper plate, a lower plate and a stand column connected with the upper plate and the lower plate, the upper plate is provided with an I-shaped groove, and the upper plate and the lower plate of the objective table, a baffle on the long side and a ventilation base body on the short side form a relatively sealed cavity; each side surface of the ventilation base is provided with two ventilation nozzles up and down; a test piece to be welded is placed on the lower plate, the clamp tightly presses the test piece through the pressing block, and the welding gun conducts welding through the long groove of the I-shaped groove. The objective table and the ventilation base are matched to form a relatively-closed protective gas chamber, the front face and the back face of a welding seam are protected by protective gas, the problems of air hole generation, oxidation, element burning loss, structure overburning and the like of the welding seam can be prevented, and the welding quality is improved.

Owner:NANJING UNIV OF SCI & TECH

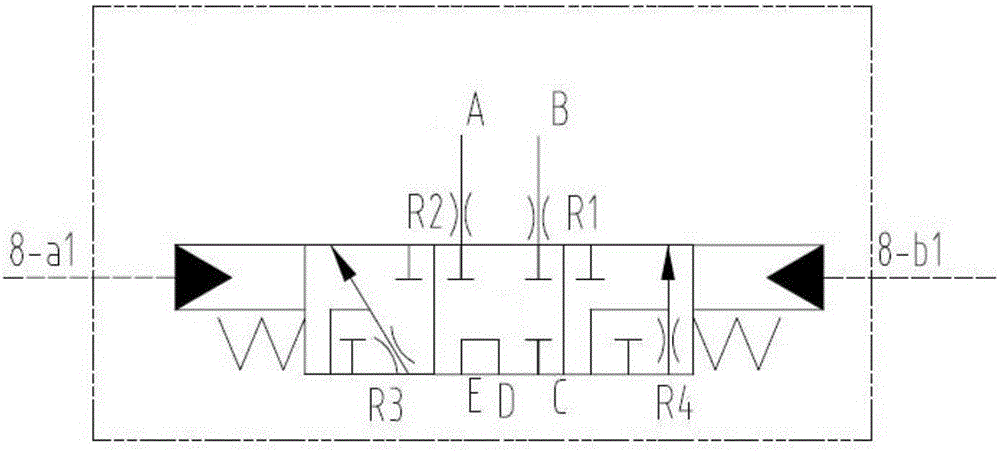

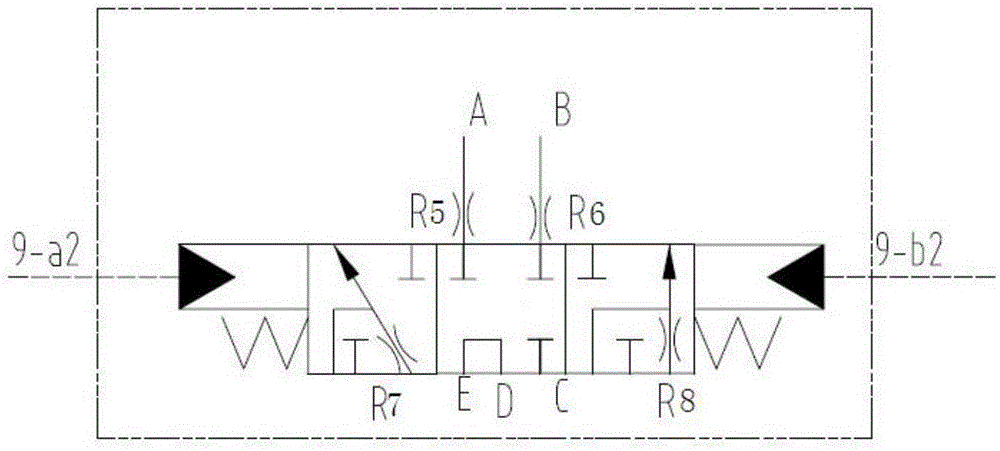

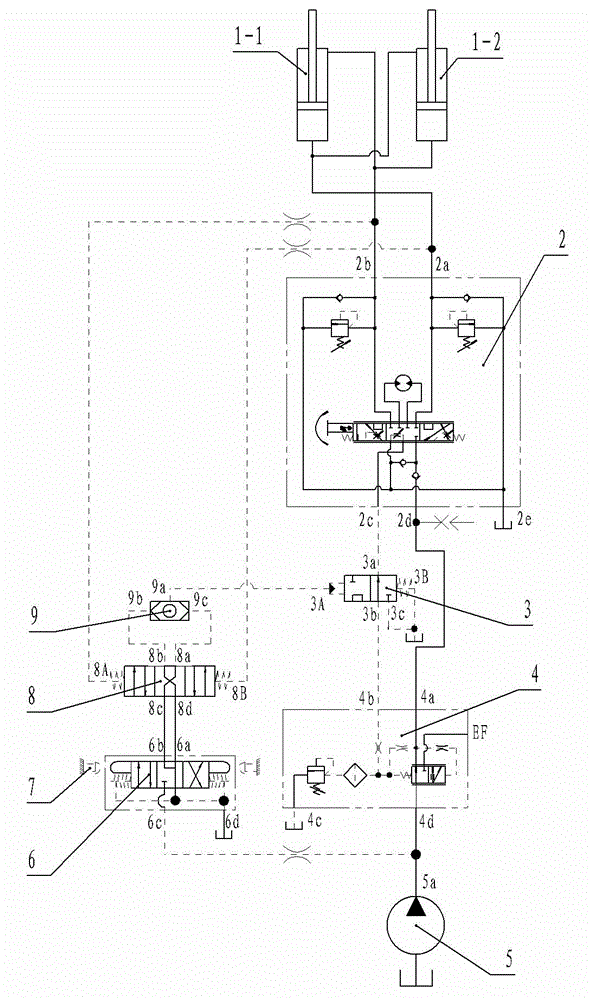

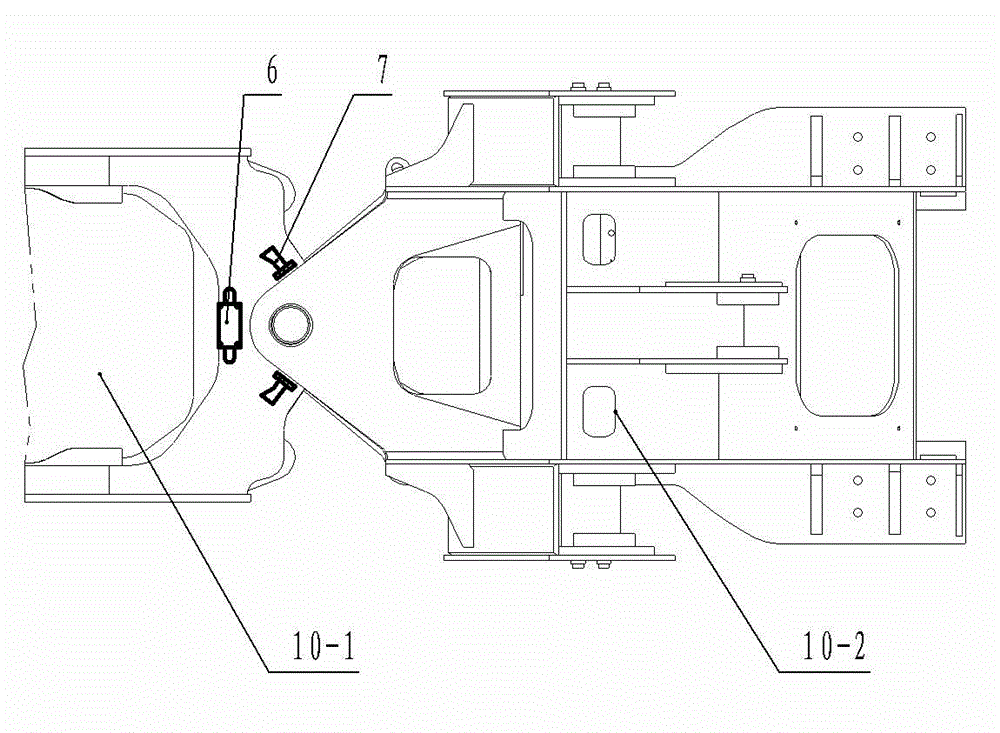

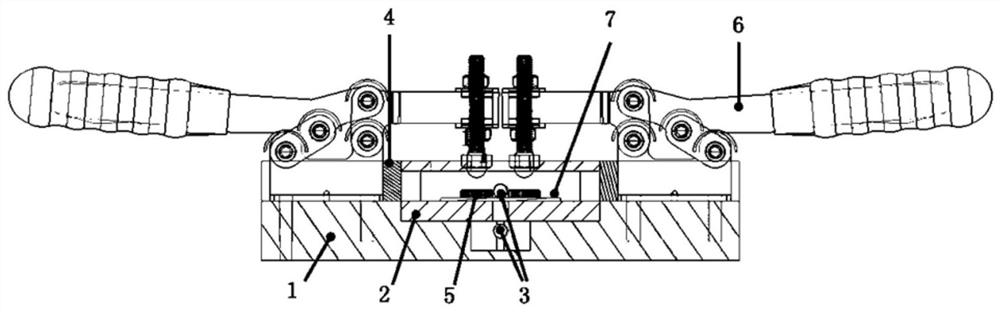

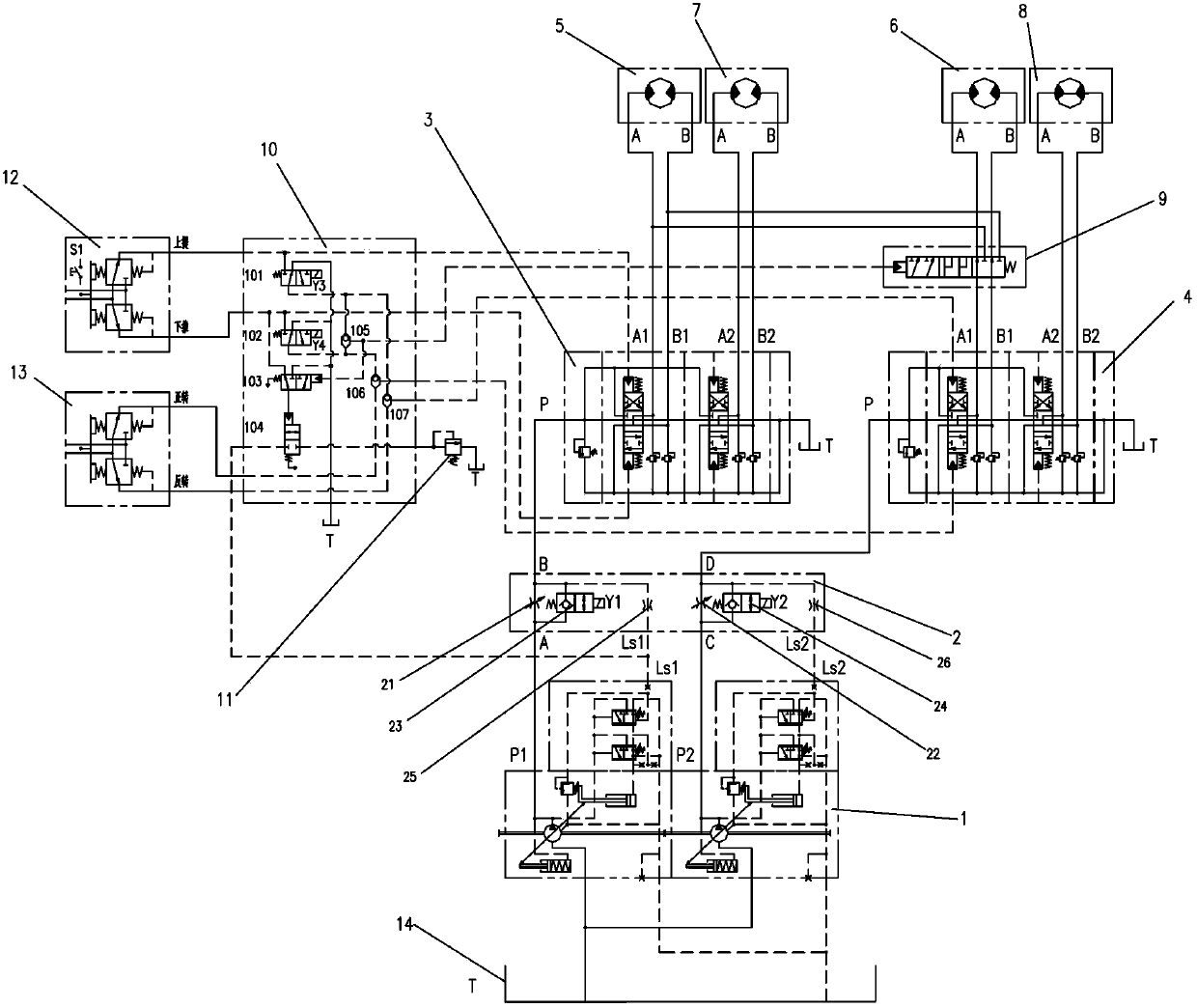

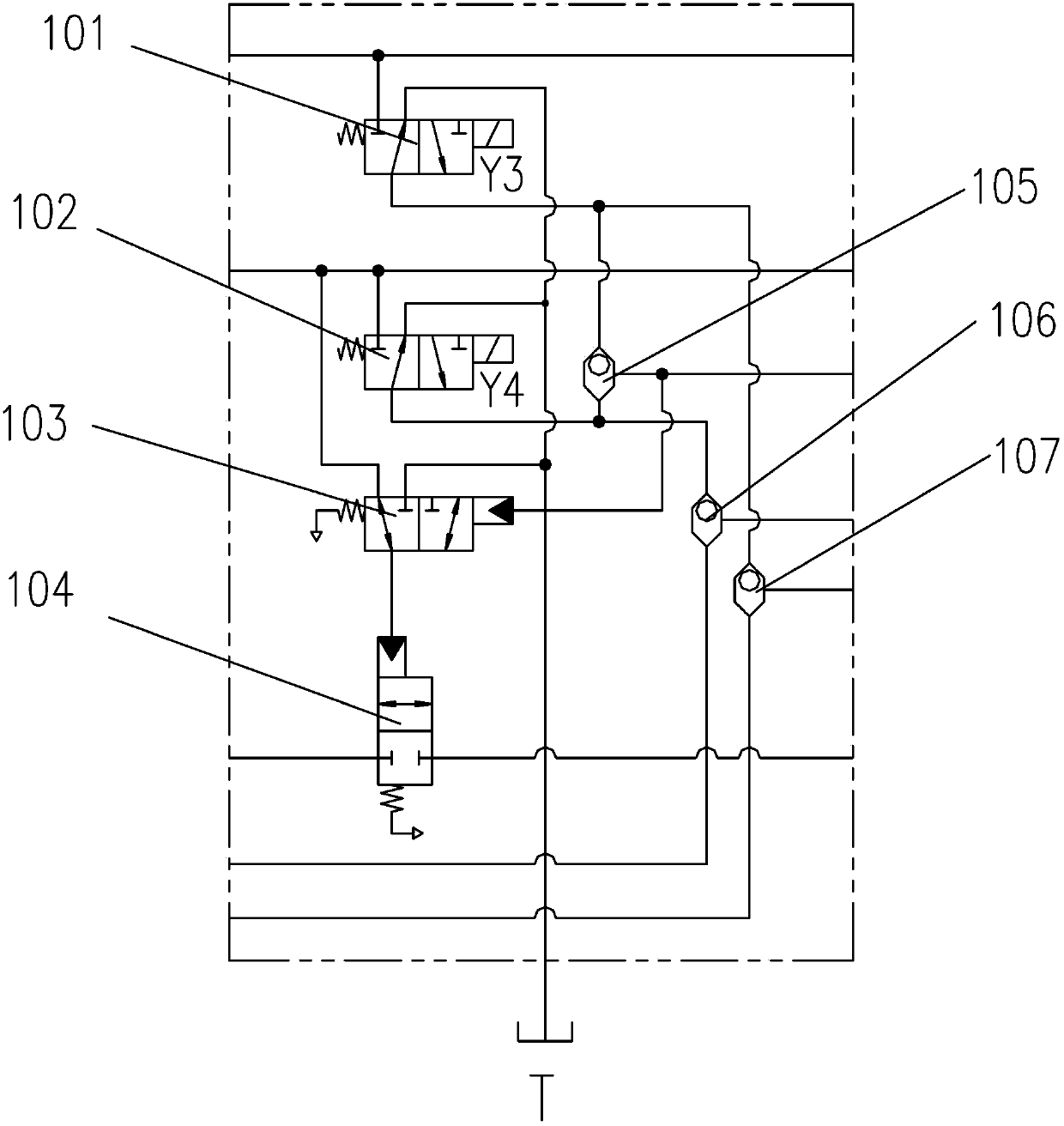

Fast propulsion hydraulic control loop of down-the-hole drill rig

ActiveCN102747949BSpeed upImprove the overall time efficiency of operationsServomotor componentsServomotorsRemote controlControl theory

Disclosed is a fast propulsion hydraulic control loop of a down-the-hole drill rig. A first multi-way reversing valve is connected with a propulsion motor. A second multi-way reversing valve is connected with a hydraulic control selector valve. The hydraulic control selector valve is connected with the propulsion motor and a rotary motor. A hydraulic control opening of the hydraulic control selector valve is connected with an output end of a propulsion rotation logic control block. The first multi-way reversing valve and the second multi-way reversing valve are connected with a propulsion guide handle and a rotation guide handle through the propulsion rotation logic control block. A double linkage load-sensitive variable pump set is connected with a remote control relief valve through the propulsion rotation logic control block. By the fast propulsion hydraulic control loop, propulsion speed of a power head under working conditions of rod-feeding empty raising and rod-discharging empty propulsion is increased effectively, cycle time of drilling operation is shortened, and comprehensive time efficiency of the operation is improved.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

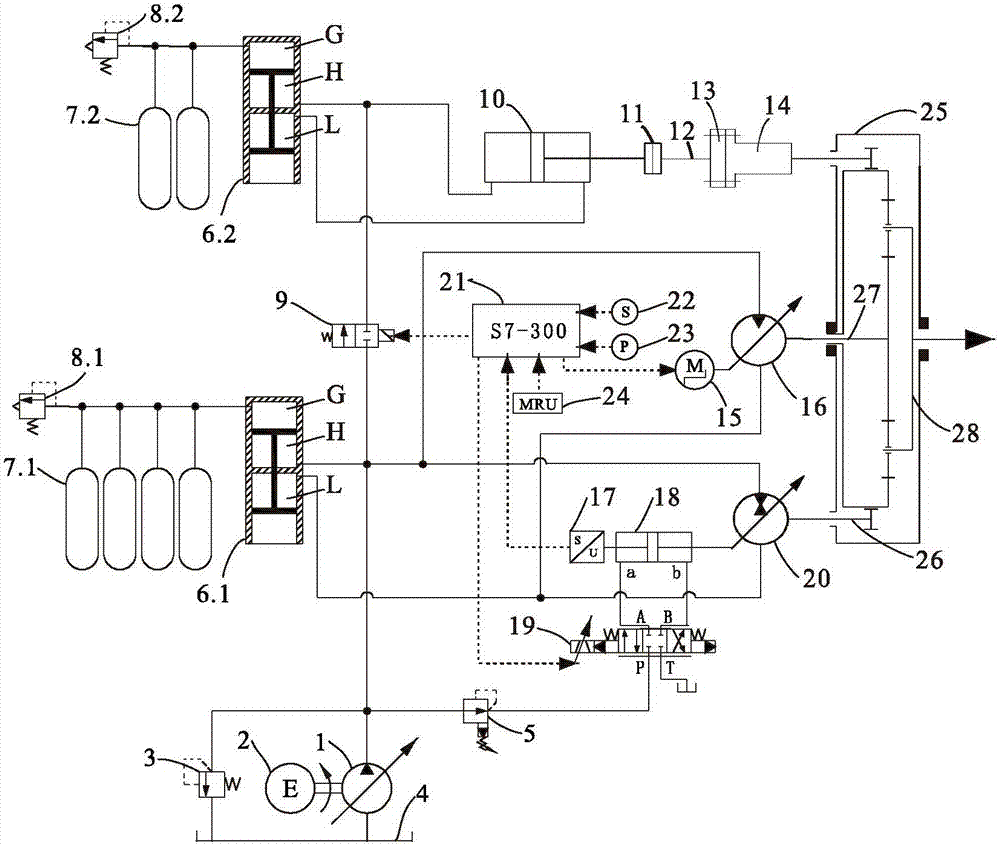

Hydraulic Drive System of Compensation Drawworks in Offshore Drilling

ActiveCN105804675BReduce loadReduce extra spaceDrilling rodsServometer circuitsEnergy recoveryGravitational potential

The invention discloses a hydraulic drive system of a compensating winch for offshore drilling. The drawworks is jointly driven by a hydraulic secondary adjustment element and a passive hydraulic cylinder to complete the heave compensation function, and the drawworks is driven by a drilling hydraulic motor to complete the automatic drilling function. During the compensation process, the passive hydraulic cylinder and its hydro-pneumatic energy storage device are used to bear all the static loads of the drilling rig, and the gravitational potential energy of the load is periodically recovered and released; the hydraulic secondary adjustment element works in a constant pressure network to overcome the compensation process The rest of the load, and use the liquid-pneumatic energy storage device to periodically recover and release the inertial kinetic energy of the drawworks slewing system. During the drilling movement, the drilling rig load gravity potential energy is recovered by using the drilling hydraulic motor and its hydraulic-pneumatic energy storage device, and then released when the drilling rig swimming system is lifted. The present invention has compact overall structure, high working efficiency and long service life of the hydraulic energy recovery system, and low engine power and energy consumption.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Load sensing heat dissipation braking variable system of loading machine

ActiveCN103171541BReduce lossesNo overflow lossBrake coolingFluid braking transmissionTraffic capacityLoad sensing

Owner:GUANGXI LIUGONG MASCH CO LTD

Fixed variable hydraulic system of mining dump truck

ActiveCN103522929BImprove steering performanceImprove performanceFluid steeringVehicle with tipping movementControl valvesTruck

Owner:GUANGXI LIUGONG MASCH CO LTD

Construction Machinery Hydraulic Steering System

ActiveCN104015798BAchieve the limitEliminate hydraulic shockFluid steeringVehicle frameControl manner

The invention discloses a hydraulic steering system for engineering machinery, and belongs to the technical field of hydraulic systems for the engineering machinery. The system comprises a steering pump and steering cylinders controlling the steering of the engineering machinery through a steering gear, wherein a priority valve is communicated with an oil way between the steering gear and the steering pump; a first hydraulic control reversing valve is communicated in series in an oil way between a third oil port of the steering gear and a second oil port of the priority valve; a shuttle valve, a second hydraulic control reversing valve and an engine-driven reversing valve are communicated in series in an oil way between the hydraulic control port of the first hydraulic control reversing valve and the first oil port of the steering pump; limiting blocks are respectively arranged on both sides, corresponding to the engine-driven reversing valve, of a vehicle frame of the engineering machinery. A hydraulic circuit control manner disclosed by the invention is simple and reliable. During the steering at a limit position of the cylinders, the system does not have a spill loss and hydraulic impact on the vehicle frame by the steering cylinders at the limit position is eliminated, so that energy is saved, rocking does not occur when the steering is finished, and the comfort of the whole vehicle is increased.

Owner:GUANGXI LIUGONG MASCH CO LTD

Construction Machinery Hydraulic Steering System

ActiveCN104029722BAchieve the limitEliminate hydraulic shockFluid steeringVehicle frameControl system

The invention discloses a hydraulic steering system for engineering machinery, which belongs to the technical field of hydraulic systems for engineering machinery. The system includes a control part and a driving part. The control part includes a steering gear; the driving part includes a steering cylinder and a steering pump. The steering pump There is a flow amplification valve connected to the oil line between the steering cylinder and the steering cylinder. The flow amplification valve has a main valve core that controls the oil flow. The two hydraulic control ports of the main valve core pass through the hydraulic control reversing valve and the two outputs of the steering gear respectively. The oil ports are connected, and the hydraulic control port of the hydraulic control reversing valve is connected to the steering pump through the motorized reversing valve and the pressure reducing valve; limit blocks are provided on both sides of the engineering machinery frame corresponding to the motorized reversing valve. . The hydraulic circuit control method of the present invention is simple and reliable. When turning at the extreme position of the oil cylinder, the system has no overflow loss, eliminating the hydraulic impact of the extreme position of the steering oil cylinder on the vehicle frame. It not only saves energy but also prevents shaking when the steering stops. Improved vehicle comfort.

Owner:GUANGXI LIUGONG MASCH CO LTD

Pump control cvt electro-hydraulic control system

InactiveCN102494128BReduce the pressure difference between inlet and outletReduce consumptionGearing controlHydraulic cylinderDrive wheel

The invention discloses a pump-controlled CVT (continuously variable transmission) electric hydraulic control system, which comprises a driving wheel hydraulic cylinder, a driven wheel hydraulic cylinder, a speed ratio control hydraulic loop, a clamping force control hydraulic loop, a controller and two pressure sensors. Effective areas of the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder are equal; the speed ratio control hydraulic loop comprises a motor II and a bidirectional hydraulic pump, and oil ports of two ends of the bidirectional hydraulic pump are respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder; the clamping force control hydraulic loop comprises a motor I, a hydraulic pump, an energy accumulator and one-way valves; an oil outlet of the hydraulic pump is respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder via the two one-way valves; and two pressure sensors are respectively mounted on pipelines communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder. The oil inlet port and the oil outlet port of the bidirectional hydraulic pump in the speed ratio control hydraulic loop are respectively communicated with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder via pipelines, pressure differences of the inlet port and the outlet port of the bidirectional hydraulic pump is reduced, consumption of power of a speed ratio adjusting hydraulic pump is not high, flow of a pressure control hydraulic pump is quite low, the pressure control hydraulic pump only supplements leakage of the system, and consumed power is lower.

Owner:CHONGQING ACADEMY OF SCI & TECH +1

An intelligent ultra-low speed stepless speed regulation hydraulic energy-saving fan

ActiveCN104005971BRealize the three-dimensional swing functionIncrease swing speed ratioPump controlPump installationsLow speedFuel tank

Owner:佛山昌能电器科技有限公司

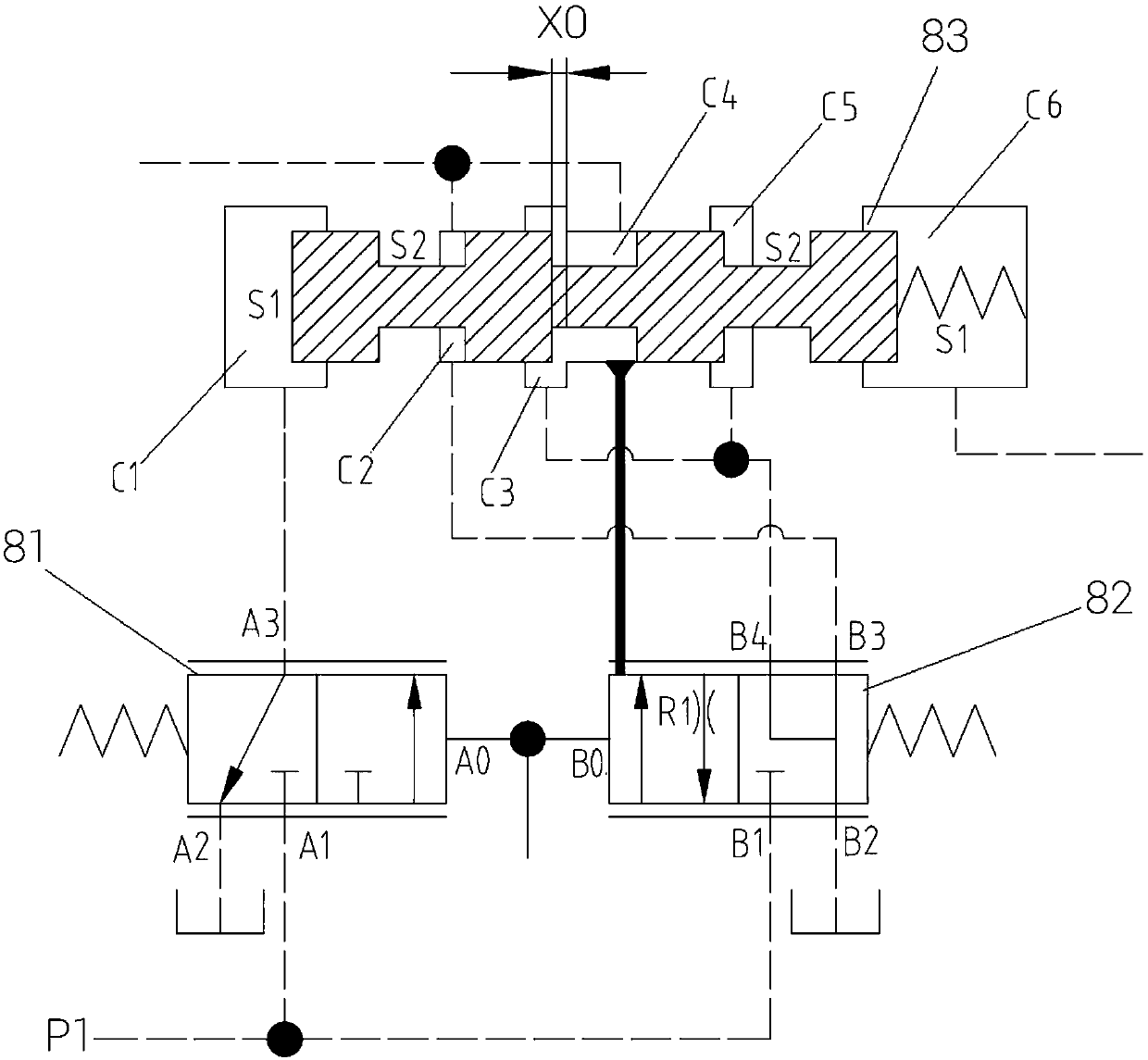

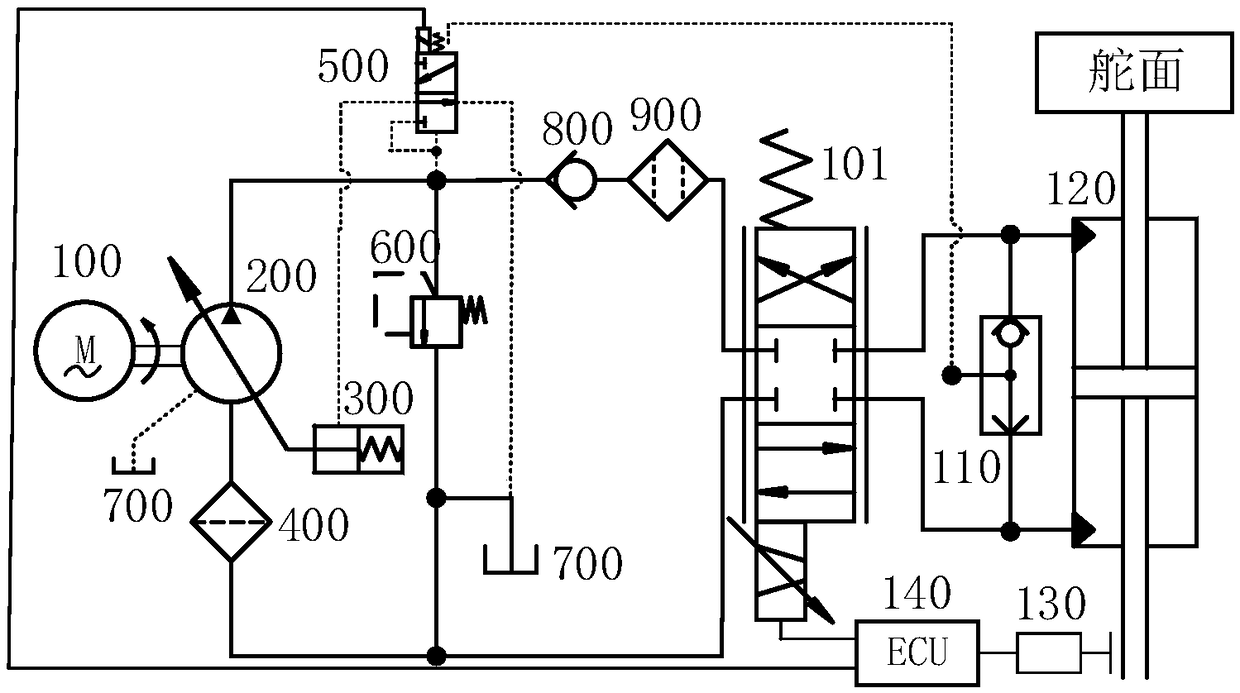

Electro-hydraulic compound servo control system

ActiveCN105351278BNo overflow lossImprove work efficiencyServomotor componentsFluid-pressure actuator componentsHydraulic cylinderLoad sensing

The invention provides a novel compound electro-hydraulic servo control system which comprises an intermediate frequency motor, an oil tank, a hydraulic cylinder, a load sensing pump, an electro-hydraulic servo valve and a shuttle valve, wherein the intermediate frequency motor is used for driving the load sensing pump; the outlet of the load sensing pump is communicated with the oil inlet of the electro-hydraulic servo valve, and the oil inlet is communicated with the outlet of the oil tank; the oil returning opening of the electro-hydraulic servo valve is communicated with the inlet of the oil tank, and the first control opening and the second control opening of the electro-hydraulic servo valve are respectively communicated with the first chamber and the second chamber of the hydraulic cylinder; the first comparing input opening and the second comparing input opening of the shuttle valve are respectively communicated with the first chamber and the second chamber of the hydraulic cylinder; the pressure signal output opening of the shuttle valve is connected with the load sensing chamber of a pressure compensator on the load sensing pump; the inlet of the pressure compensator is communicated with the outlet of the load sensing pump, the control opening of the pressure compensator is communicated with the variable displacement mechanism of the load sensing pump, and the oil returning opening of the pressure compensator is communicated with the oil tank. According to the novel compound electro-hydraulic servo control system, the outlet working pressure of the load sensing pump can be changed along with the size of load, and the purpose of energy saving is achieved.

Owner:SHANGHAI XINYUE METER FACTORY

Constant-tension winch hydraulic system

ActiveCN114060326ASolve the problem of continuous overflow and high heat generationNo overflow lossServomotor componentsAccumulator installationsHydraulic motorEngineering

The invention discloses a constant-tension winch hydraulic system. An oil outlet of the power pump set is communicated with an oil inlet of the pressure reducing valve, an oil outlet of the pressure reducing valve is communicated with a first oil port of the main control valve, a second oil port of the main control valve is communicated with a forward oil inlet of the hydraulic motor through a forward oil way, and a forward oil outlet of the hydraulic motor is communicated with a third oil port of the main control valve through a reverse oil way. A fourth oil port of the main control valve is communicated with the oil tank, an oil inlet of the main overflow valve is located on one side of the oil outlet side of the first one-way passage and communicated with the forward rotation oil way, and an oil outlet of the main overflow valve is communicated with the reverse rotation oil way through a second oil way. The oil inlet of theoverflow valve is regulated to be connected with one end of a reversing valve. The other end of the reversing valve is communicated with an oil outlet of the first overflow valve and an oil outlet of the second overflow valve, an oil inlet of the first overflow valve is communicated with a control port of the pressure reducing valve, and an oil inlet of the second overflow valve is communicated with a control port of the main overflow valve. The set value of the second overflow valve is a fixed pressure value higher than the set value of the first overflow valve, so that overflow loss can be reduced.

Owner:上海中车艾森迪海洋装备有限公司

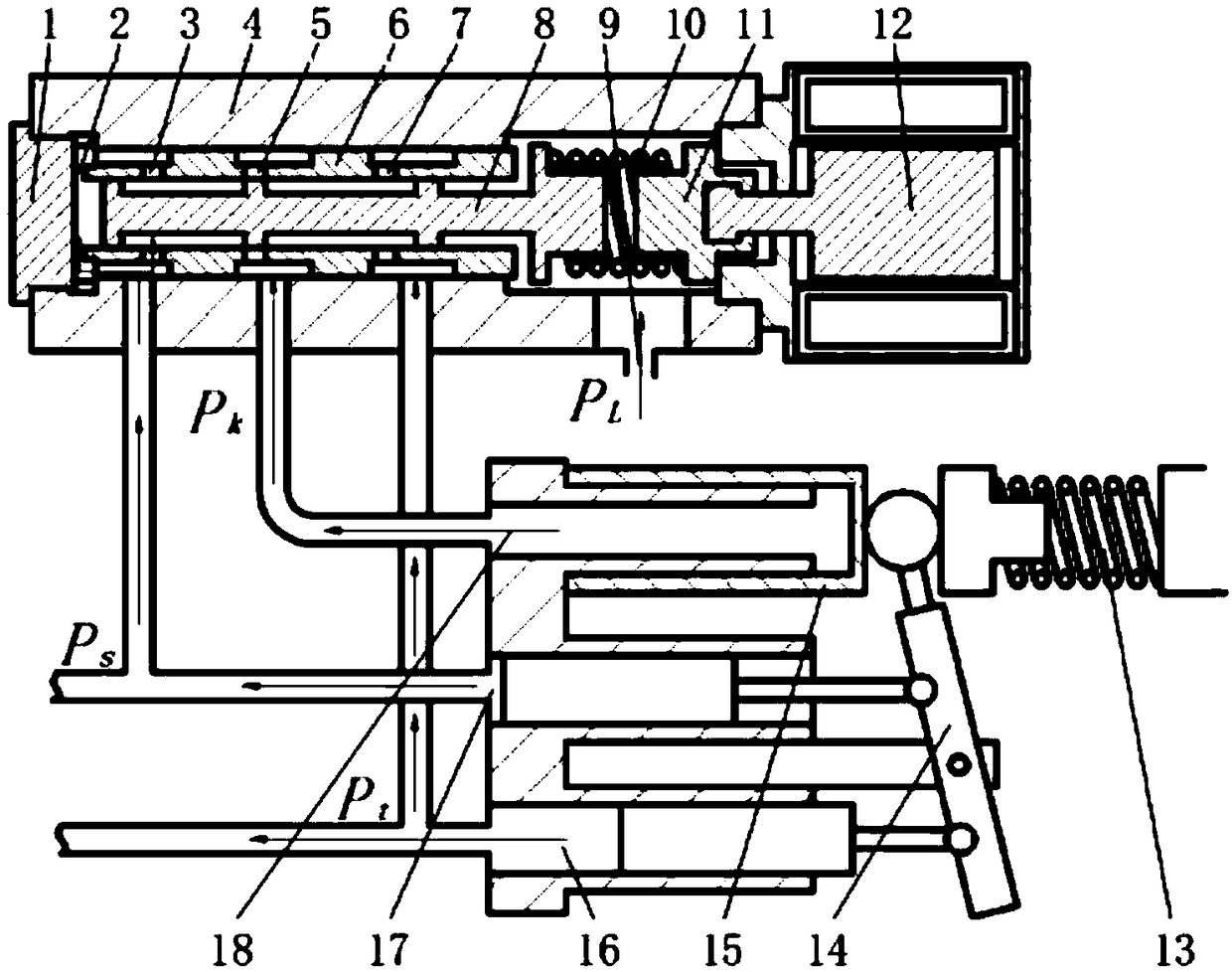

Electric-hydraulic proportional load-sensitive pump and pump valve joint control servo system

ActiveCN109441906AFast dynamic responseImprove work efficiencyServomotor componentsPositive-displacement liquid enginesDifferential pressureControl theory

The invention discloses an electric-hydraulic proportional load-sensitive pump and a pump valve joint control servo system. The electric-hydraulic proportional load-sensitive pump mainly comprises anend cap, a shell, a valve bush, a valve element, a pressure adjusting spring, a push rod, a proportion electro-magnet, a reset spring, a swash plate and a control piston. The work pressure PS of an outlet of the load-sensitive pump keeps constant differential pressure changes along with a load PL, the constant differential pressure can be adjusted through the proportion electro-magnet, the differential pressure adjusting response is fast, and the dynamic response speed of the electric-hydraulic proportional load-sensitive pump can be greatly increased. The pump valve joint control servo systemis free of overflow loss, and the work efficiency of the pump valve joint control servo system can be greatly improved while the high-frequency dynamic characteristic is met.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com