Electric-hydraulic proportional load-sensitive pump and pump valve joint control servo system

A load-sensing pump and electro-hydraulic proportional technology, applied in servo motor components, fluid pressure actuation system components, pumps, etc., can solve the problems of limited output force of electromagnetic proportional valves, affecting response speed, large force, etc., to achieve Fast response to differential pressure adjustment, improved dynamic response, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

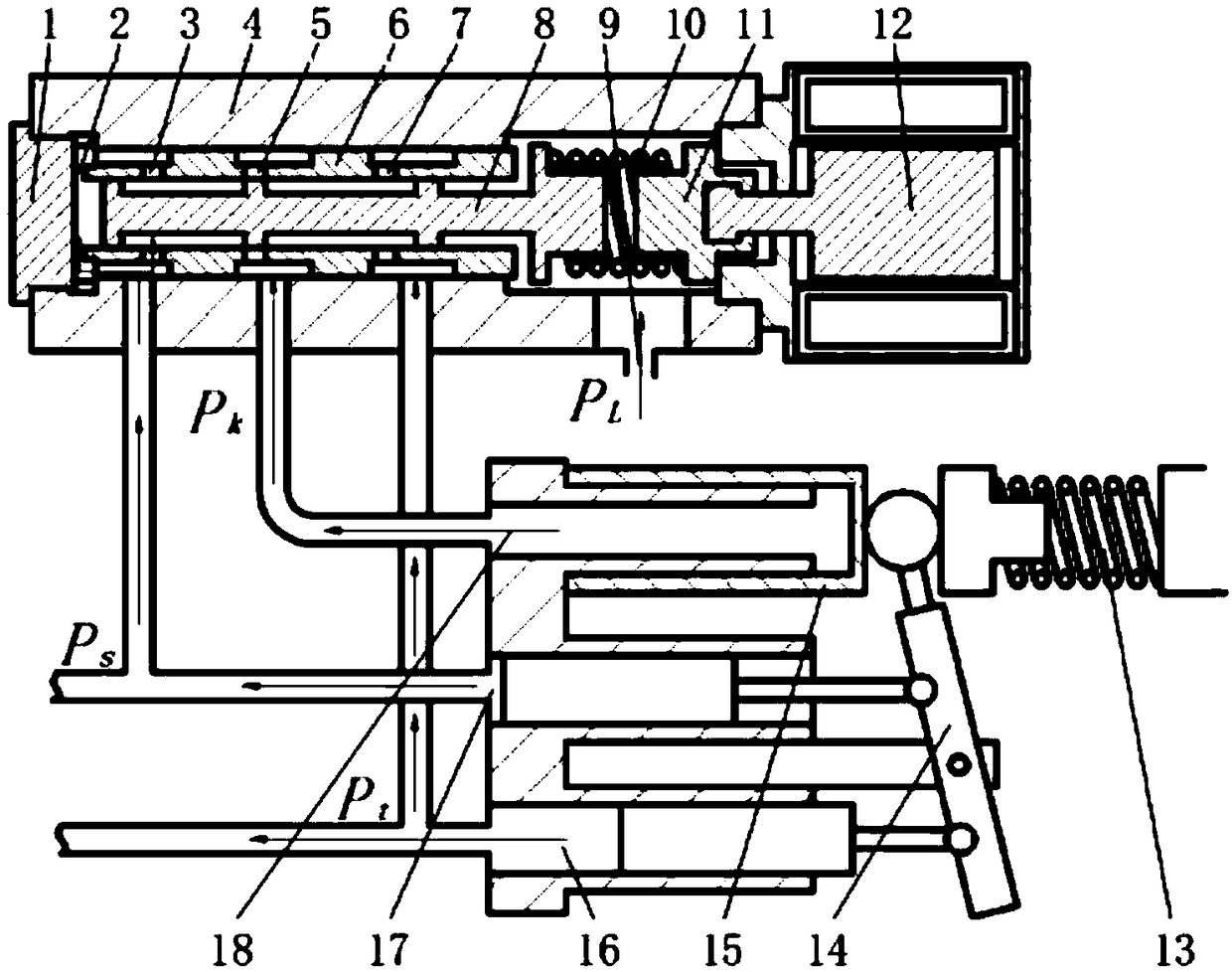

[0025] Such as figure 1 As shown, an electro-hydraulic proportional load sensitive pump provided in this embodiment includes: a plug 1, a housing 4, a valve sleeve 6, a valve core 8, a pressure regulating spring 10, a push rod 11, a proportional electromagnet 12, a return Spring 13, swash plate 14 and control piston 15; the valve sleeve 6 is located inside the housing 4, close to the first end of the housing, and is in interference fit with the inner wall of the housing 4, and the valve core 8 is located inside the valve sleeve 6; the pressure regulating spring 10 and the push rod 11 are sequentially arranged inside the housing 4, close to the second end of the housing 4, and the pressure regulating spring 10 is located in the between the spool 8 and the push rod 11; the proportional electromagnet 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com