Hydraulic driving system for offshore drilling compensation winch

A technology for marine drilling and drive systems, applied in fluid pressure actuation system components, drilling equipment, fluid pressure actuation devices, etc. It can solve the problems of poor explosion-proof performance of variable frequency motors, high installed power and energy consumption, and large motor heat generation, etc. problems, achieve the effects of reducing platform load and occupied space, high power density, and high energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

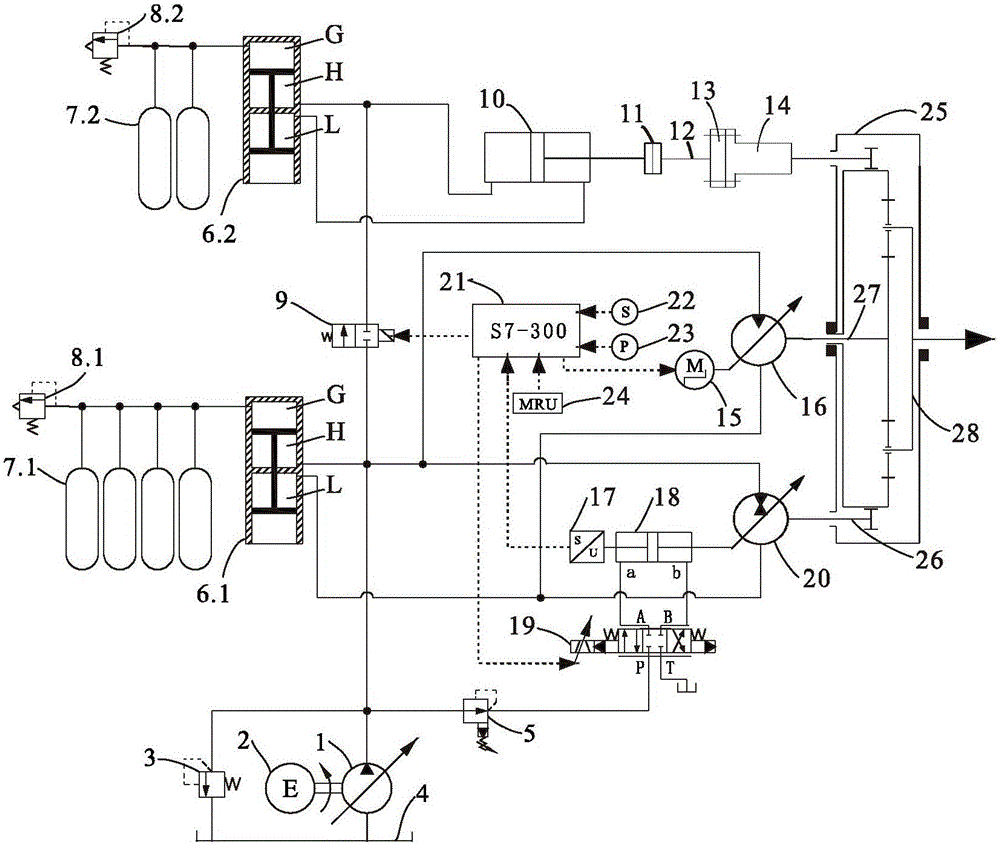

[0017] Such as figure 1 As shown, the hydraulic drive system mainly includes hydraulic secondary adjustment element 20, passive hydraulic cylinder 10, drill hydraulic motor 16, first double-piston accumulator 6.1, second double-piston accumulator 6.2, first high-pressure gas Bottle 7.1, second high-pressure cylinder 7.2, constant pressure variable pump 1, variable hydraulic cylinder 18, electro-hydraulic servo valve 19, stepper motor 10. During installation, the hydraulic secondary adjustment element 20 is mechanically connected to the outer ring gear power input shaft 26 of the differential planetary reducer 25, and the swash plate of the hydraulic secondary adjustment element 20 is mechanically connected to the piston rod of the variable hydraulic cylinder 18; the passive hydraulic cylinder The piston rod of 10 is mechanically connected to one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com