Load sensing heat dissipation braking variable system of loading machine

A technology of load sensing and variable system, which is applied in the direction of brakes, cooling brakes, hydraulic brake transmissions, etc., can solve the problems that new technologies are rarely promoted, and achieve the effect of easy implementation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

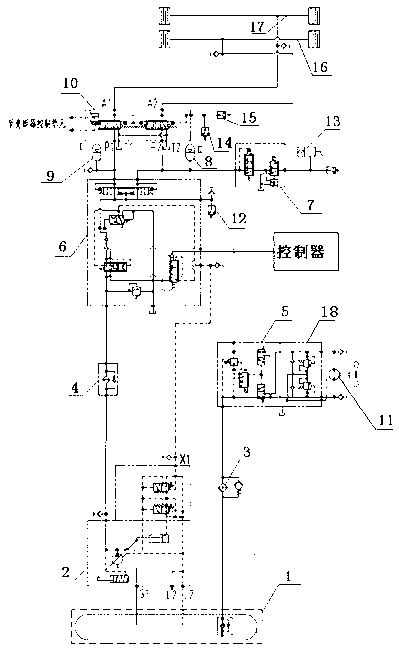

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The present invention mainly consists of a variable displacement plunger pump 2, a parking brake valve 7, a first accumulator 8, a second accumulator 9, a brake valve 10 and a load sensing filling valve 6. Thermal braking system. The pressure oil port of the load sensing filling valve 6 is connected to the pressure oil port of the variable plunger pump 2, and provides pressure oil to the accumulator and the working device in the liquid charging state, and outputs the pressure oil for controlling the LS. To control the variable plunger pump to provide the required flow to the system, always keep the priority of filling.

[0015] The temperature signal of the heat dissipation system is converted into an electrical signal to control the electric proportional pressure reducing valve in the load sensing filling valve, the filling priority is given, and the reversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com