Energy-saving design method for variable-load servo control system

A technology of a servo control system and a design method, which is applied to servo meter circuits, servo motors, fluid pressure actuating system components, etc., can solve problems such as low energy utilization rate, achieve high energy utilization rate, high efficiency, and improve energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

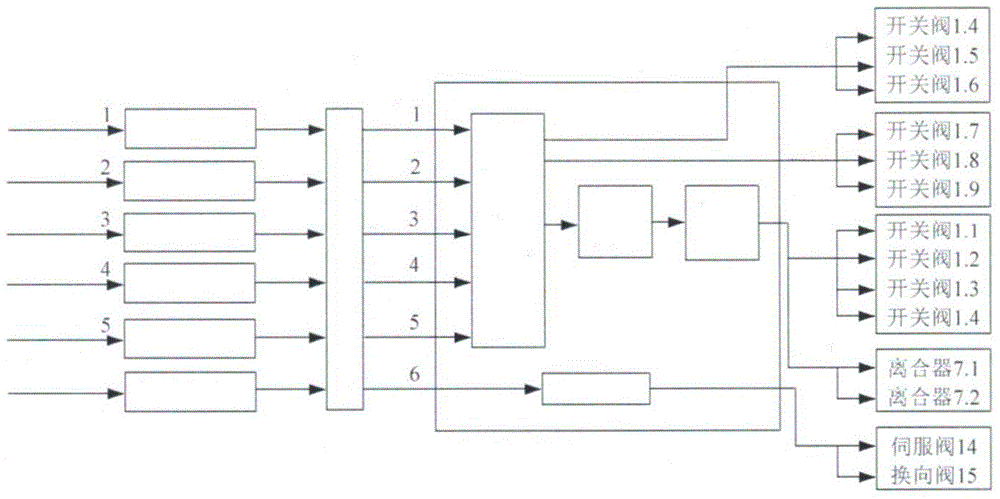

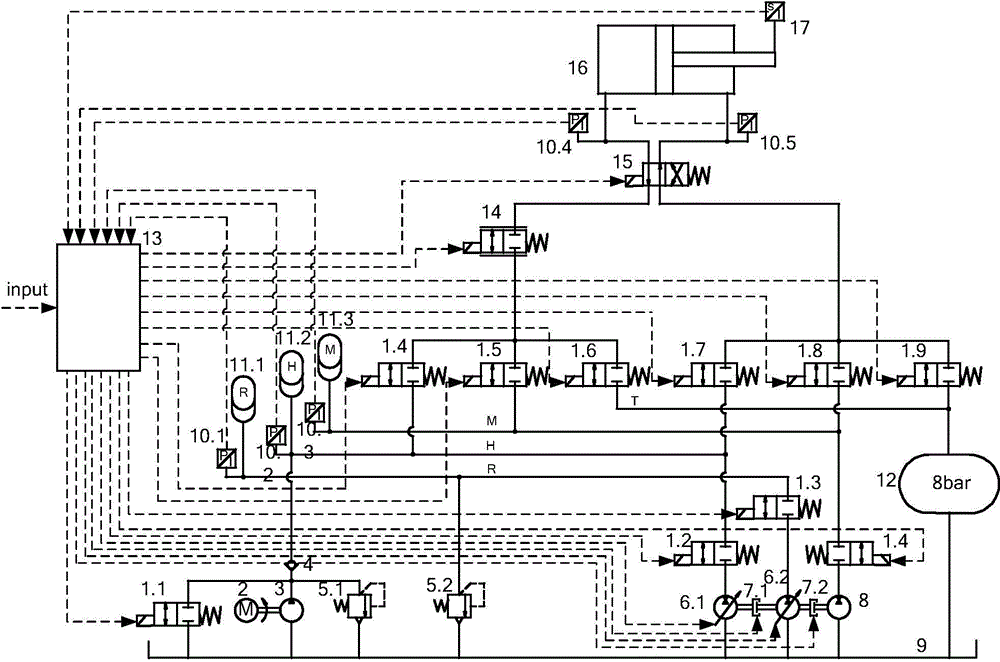

[0024] The variable load servo control energy-saving system is mainly composed of four oil circuits, which are energy storage oil circuit R and three high-pressure oil circuits H, medium-pressure oil circuit M, and low-pressure oil circuit T with different pressure levels. The quantitative pump 3 in the system is driven by the motor 2. The outlet of the quantitative pump is divided into three oil circuits, which are respectively connected with the oil inlet of the check valve 4, the safety valve 5.1 and the on-off valve 1; the oil outlet of the safety valve 5.1 and the on-off valve 1 It is directly connected to the fuel tank 9; the oil outlet of the check valve 4 is connected to the high-pressure oil circuit H, and the high-pressure oil circuit H is respectively connected to the high-pressure accumulator 11.2, the pressure sensor 10.2, the left and right double switch valves 1.4, 1.7 oil inlets, energy The on-off valve 1.2 of the transfer unit is connected to the oil inlet; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com