Preparation method of composite photocatalyst with high oxidation activity carbon dots and nickel sulfide

A technology of activated carbon and nickel sulfide, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low utilization rate of visible light, low loading activity, and weak photooxidative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

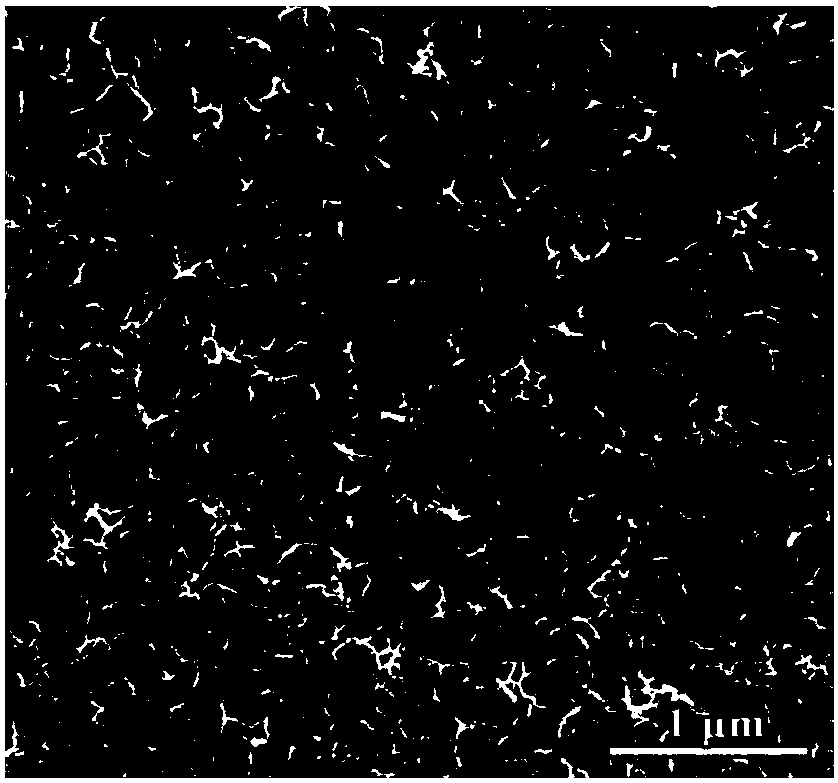

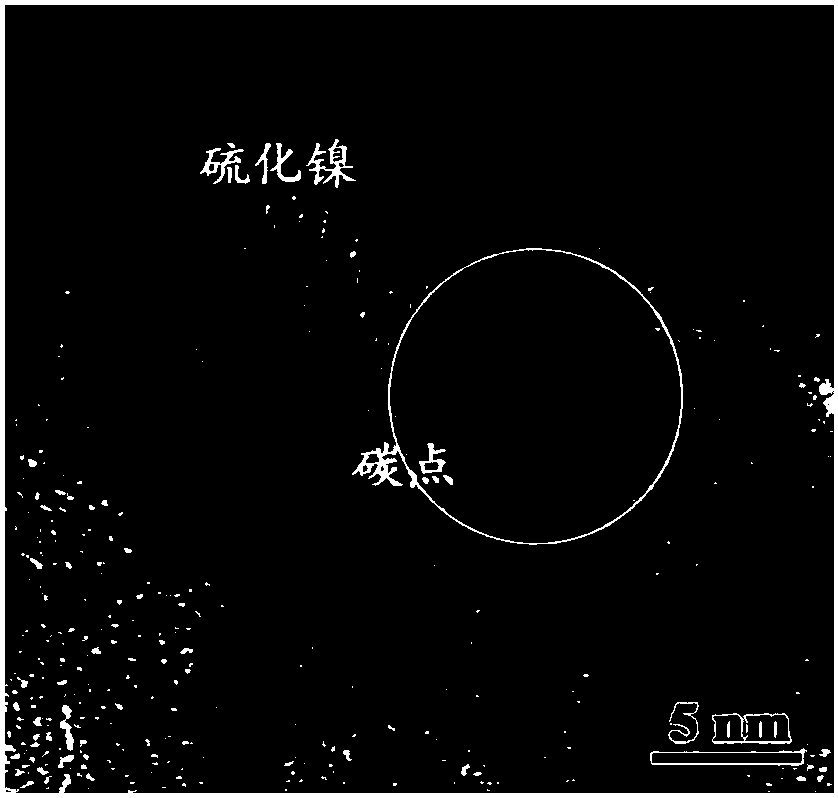

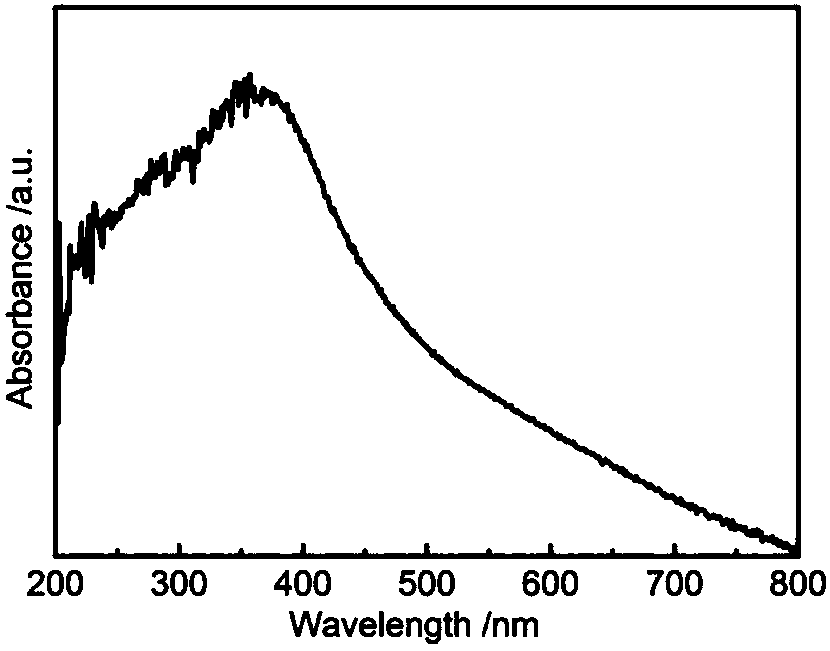

[0017] The preparation method of composite photocatalyst with high oxidation activity carbon point and nickel sulfide adopts the following steps:

[0018] (1) Dissolve p-phenylenediamine in ethanol, the weight ratio of p-phenylenediamine to ethanol is 1:80, then put the mixed solution of p-phenylenediamine and ethanol into the lining of polytetrafluoroethylene hydrothermal reaction kettle middle; then put the polytetrafluoroethylene hydrothermal reaction kettle lining into the steel tank and seal it, put it into the blast drying oven and heat it to 160-180°C, keep it warm for 8-12 hours, and then cool it in the air to obtain carbon dot suspension;

[0019] (2) Get a nickel foam disc with a diameter of 30mm, a thickness of 2-3mm, an aperture of 0.01-2mm, and a through-hole ratio≥98%, and ultrasonically clean the nickel foam disc with acetone and 3mol / L hydrochloric acid solution for 10- 15 minutes, and then rinse with ethanol 3-5 times;

[0020] (3) nickel foam disc is put in...

Embodiment 1

[0023] In this embodiment, the preparation method of the composite photocatalyst with high oxidation activity carbon point and nickel sulfide adopts the following steps:

[0024] (1) 1g p-phenylenediamine is dissolved in 80g ethanol, then the mixed solution of p-phenylenediamine and ethanol is put into the lining of polytetrafluoroethylene hydrothermal reaction kettle; then polytetrafluoroethylene hydrothermal reaction Put the inner lining of the kettle into a steel tank and seal it, put it into a blast drying oven and heat it to 160°C, keep it warm for 8 hours, and then cool it in the air to obtain a carbon dot suspension;

[0025] (2) Get the foamed nickel disc with a diameter of 30mm, a thickness of 2mm, an aperture of 0.01mm, and a through-porosity of 99%, and ultrasonically clean the foamed nickel disc with acetone and 3mol / L hydrochloric acid solution for 10 minutes, and then Rinse 3 times with ethanol;

[0026] (3) Put the nickel foam disc into a beaker with the same i...

Embodiment 2

[0036] In this embodiment, the preparation method of the composite photocatalyst with high oxidation activity carbon point and nickel sulfide adopts the following steps:

[0037] (1) 2g p-phenylenediamine is dissolved in 160g ethanol, then the mixed solution of p-phenylenediamine and ethanol is put into the lining of polytetrafluoroethylene hydrothermal reaction kettle; then polytetrafluoroethylene hydrothermal reaction Put the inner lining of the kettle into a steel tank and seal it, put it into a blast drying oven and heat it to 180°C, keep it warm for 12 hours, and then cool it in the air to obtain a carbon dot suspension;

[0038] (2) Get a nickel foam disc with a diameter of 30mm, a thickness of 3mm, an aperture of 2mm, and a through-porosity of 98%, and ultrasonically clean the foam nickel disc with acetone and 3mol / L hydrochloric acid solution for 15 minutes, and then use ethanol Rinse 5 times;

[0039] (3) Put the foamed nickel disc into a beaker with the same inner d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com