Efficient spiral cutter household waste processor

A technology of garbage disposer and spiral, applied in the field of high-efficiency spiral cutter household garbage disposer, can solve the problems of unsightly, not easy to curl the blade, not easy to popularize, etc., achieve simple and clean appearance and structure, improve pulverizing effect, and good pulverizing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

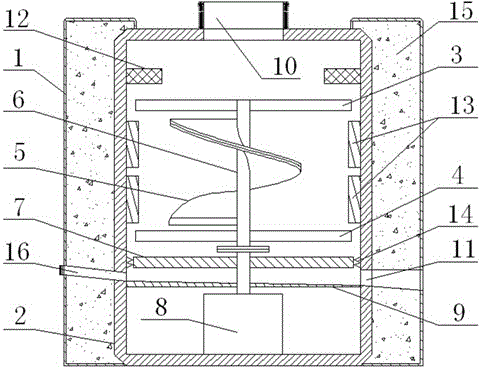

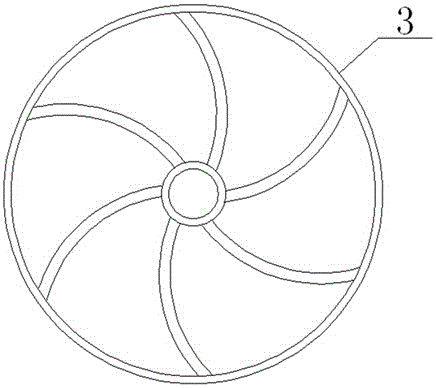

[0021] Such as figure 1 , figure 2 As shown, a high-efficiency spiral cutter household garbage disposer is specially configured as the following structure: it includes a body 2, an inlet 10 is provided on the top of the body 2, a motor 8 is provided on the bottom surface of the body 2, and an output shaft of the motor 8 A rotating shaft 6 is connected, and an upper knife rest 3 and a lower knife rest 4 are sequentially connected on the rotating shaft 6. The upper knife rest 3 and the lower knife rest 4 are respectively composed of an outer ring, a blade and an inner ring, and one end of the blade is connected to the The inner profile of the outer ring, the other end of the blade is connected to the outer profile of the inner ring, the rotating shaft 6 between the upper tool rest 3 and the lower tool rest 4 is provided with a spiral knife 5, and the lower part of the body 2 is provided with an outlet 11, A grinding disc 7 is arranged inside the body 2, and the grinding disc 7...

Embodiment 2

[0024] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is particularly adopted: the inner wall of the body 2 between the upper knife rest 3 and the lower knife rest 4 is provided with two sets of crushing teeth 13, and the domestic garbage cut by the upper knife rest 3 passes through The gap of the upper tool holder 3 flies to the bottom of the body 2, and is cut again by the screw knife 5 or thrown out by the surface of the screw knife 5, and then hits the crushing teeth 13, and the crushing teeth 13 further cut the domestic garbage Or crushing, the crushing effect is better than any of the above-mentioned embodiments.

Embodiment 3

[0026] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is particularly adopted: the inner wall of the body 2 is provided with abrasive grains 14 used in conjunction with the grinding disc 7, and the grinding disc cooperates with the abrasive grains 14 arranged on the body 2 to increase the amount of domestic waste. The friction effect with the inner wall of the body 2 makes the domestic waste better squeeze and friction between the grinding disc 7 and the body 2, so that the crushing effect of the domestic waste is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com