Deep drawing die for compressor rack

A technology for deep drawing dies and compressors, applied in the field of stamping dies, which can solve the problems of easy cracking or wrinkling, low surface finish, and large workpiece processing errors, so as to reduce wrinkling and cracking, high surface finish, and prevent The effect of workpiece springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

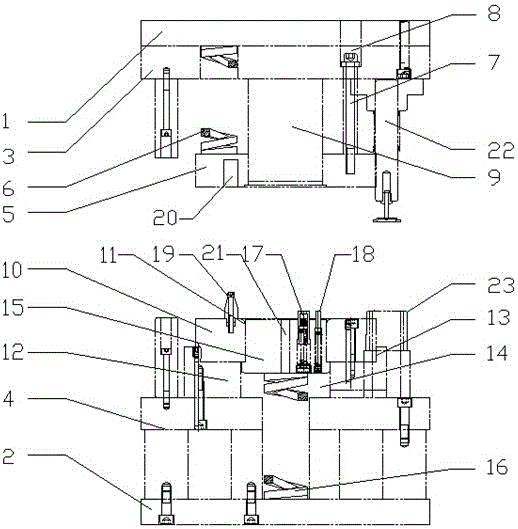

[0027] Such as figure 1 and figure 2 Shown, a kind of drawing die of compressor frame among the present invention comprises:

[0028] Upper template 1 and lower template 2;

[0029] A punch pad 3 and a die pad 4, the punch pad 3 is arranged on the lower surface of the upper template 1, and the die pad 4 is arranged on the upper surface of the lower template 2;

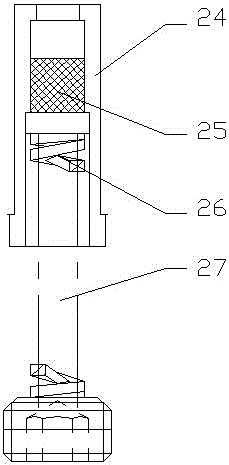

[0030] The guide sleeve seat 5, the guide sleeve seat 5 is located below the punch pad 3, the two ends of the punch pad 3 are respectively penetrated with an upper spring 6 and a limit post 7 along the vertical direction, and the upper spring 6 Both ends are respectively fixed on the upper template 1 and the guide sleeve seat 5, and the punch pad 3 is provided with a limit groove 8 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com