Artificial nail back film and manicure treatment method applying the same

A technology of artificial nails and back stickers, applied in manicure or pedicure tools, applications, clothing, etc., can solve problems such as insufficient stickiness, detachment of fake pieces, and easy detachment of fake pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

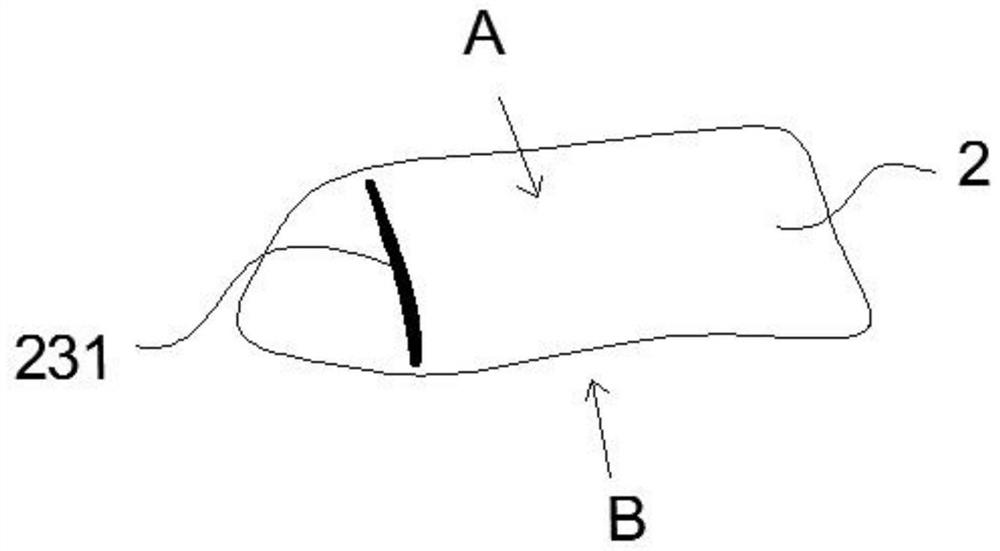

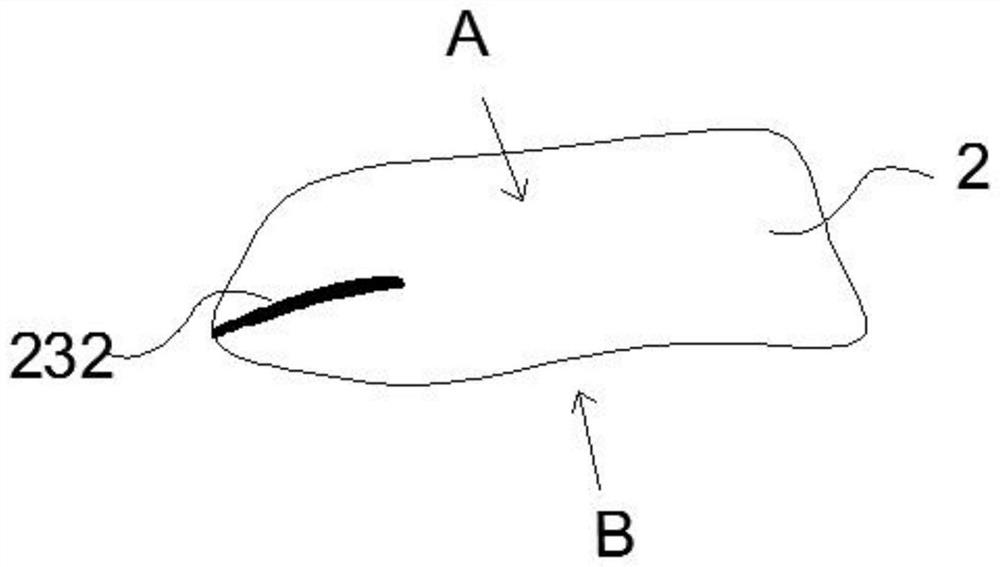

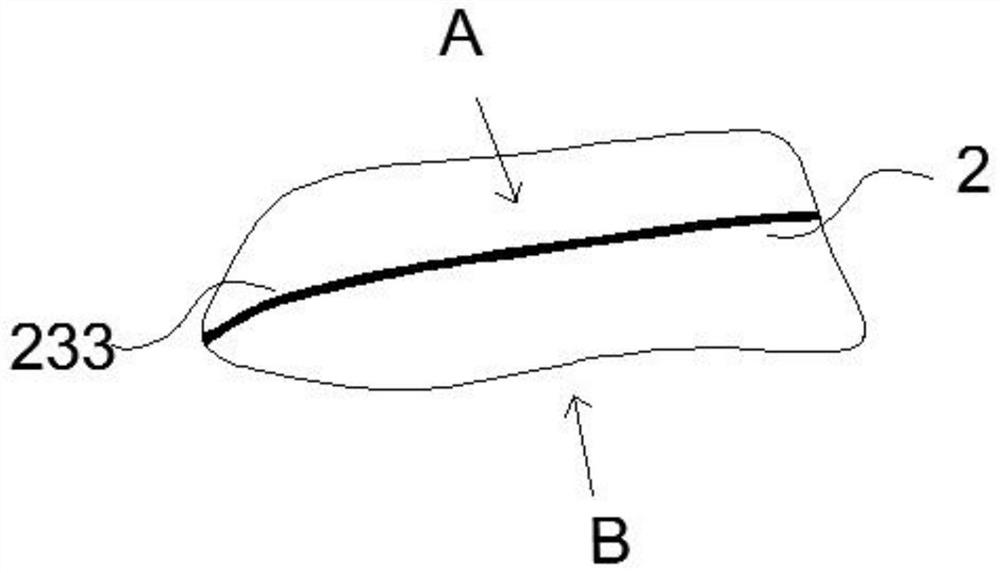

[0048] An artificial nail back film 2 is made by cutting a pre-coated film with a thickness ranging from 0.016 mm to 0.1 mm according to a certain size. The pre-coated film here can be a waterproof PE pre-coated film, PU Pre-coated film, BOPP pre-coated film, or other pre-coated films with a thickness ranging from 0.016mm to 0.1mm;

[0049] Here, the thickness of the pre-coating film preferably ranges from 0.016 mm to 0.06 mm, for example, a commercially available BOPP pre-coating film with a thickness of 0.03 mm is used.

[0050] The specifications of the back film 2 can adopt a unified larger specification, which is slightly larger than conventional artificial nails, and can also be produced according to artificial nails of different sizes, that is, when the back film 2 is attached to the back of the artificial nail 1, it can completely cover the artificial nails. The back of the nail 1 has a width ranging from 5mm to 30mm, and a length ranging from 5mm to 30mm, which can be...

Embodiment 2

[0057] Based on the artificial nail back sticking film described in embodiment 1, the specific method of applying it to carry out manicure treatment includes the following process:

[0058] (1) Nail surface cleaning treatment;

[0059] (2) nail surface isolation and protection treatment;

[0060] (3) Artificial nail back protection treatment;

[0061] (4) bonding treatment;

[0062] (5) cleaning treatment after bonding;

[0063] (6) Artificial nail removal treatment;

[0064] In the above process, process (2) and process (3) can be performed simultaneously or the order can be reversed, and process (5) is a non-essential processing step that can be omitted.

[0065] Described treatment process (1) namely nail surface cleaning treatment concrete operation can be:

[0066] (1.1) Simply repair the shape of nail 4, this operation is not necessary;

[0067] (1.2) Clean the dust on the surface of the nail 4, use tools such as dead skin to deal with the dead skin and keep the fi...

Embodiment 3

[0094] The difference between embodiment 3 and embodiment 2 is only to add an operation in step (4), that is, fix or directly place a piece of thin cotton 9 of suitable size on the described nail protective film 5, thin cotton is a rectangular block artificial Fiber material or thin piece of cotton, put glue 7 drops on the thin cotton 9 of the protective film, the amount is just to soak the thin cotton 9, but do not let the glue 7 overflow or overflow, use the tip of the glue bottle to put the glue Gently bring it to the protective film that is not covered with cotton. The amount of glue at this time is similar to or slightly less than the state of applying a thin layer of nail polish primer. After soaking the thin cotton 9 with glue 7, put it on The artificial nail patch 3 sticks on the treatment layer 6, presses it for a period of time, and the glue solidified layer 70 formed by the glue 7 dries out and forms a mixed solidified layer 71 with the thin cotton 9. The rear end 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com