Hydraulic internal mold device for concrete box girder

A concrete box girder and inner mold technology, applied in the direction of ceramic molding core, ceramic molding mandrel, etc., can solve the problems of only about 120°, the inability to realize hydraulic integral demoulding, and the difficulty of integral hydraulic demoulding, etc., to achieve The effect of increasing the shrinkage, reducing the labor intensity of construction, and saving the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

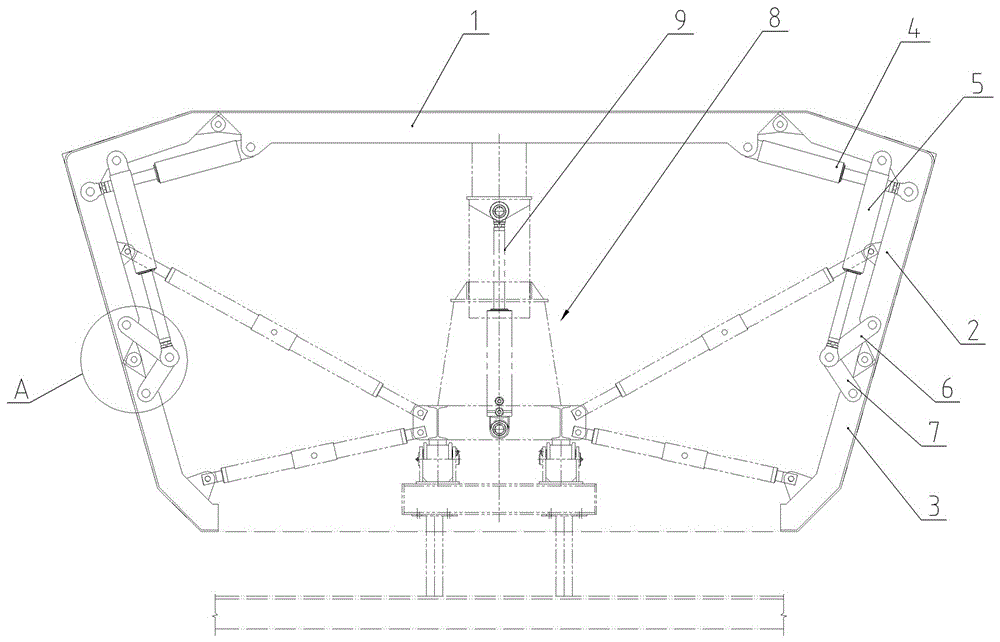

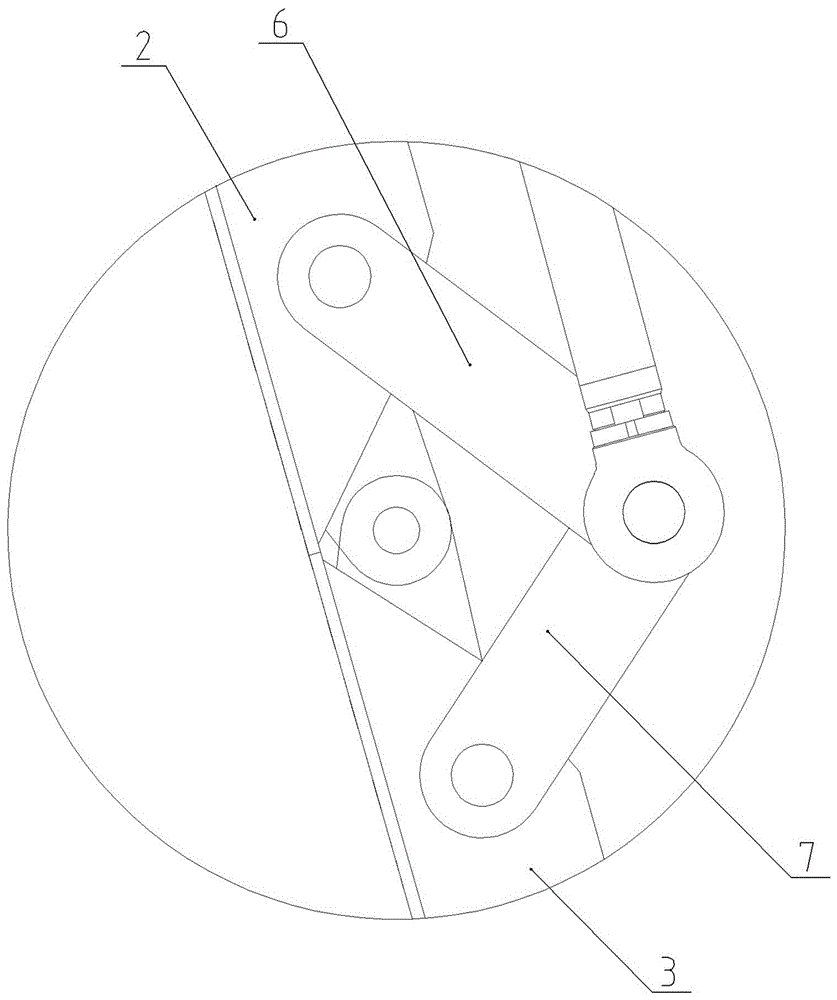

[0024] Embodiment one, such as Figure 1 to Figure 4 As shown, the hydraulic internal formwork device of the concrete box girder disclosed in this embodiment has a formwork system including a top formwork 1 , an upper movable formwork 2 and a lower movable formwork 3 . The upper mold 2 and the lower movable mold 3 are respectively hinged on both sides of the top mold 1 in turn, and a number of hinge seats are respectively arranged on the longitudinal side edges of each template, and the hinge seats between adjacent templates are hinged as a whole through hinge shafts. The top mold 1, the upper movable mold 2 and the lower movable mold 3 enclose the cross-sectional shape of the inner cavity of the concrete box girder.

[0025] An oil cylinder A4 is hinged between the top mold 1 and the upper movable mold 2, and an oil cylinder B5 is hinged between the upper movable mold 2 and the lower movable mold 3.

[0026] The two ends of the oil cylinder A4 and the oil cylinder B5 both ad...

Embodiment 2

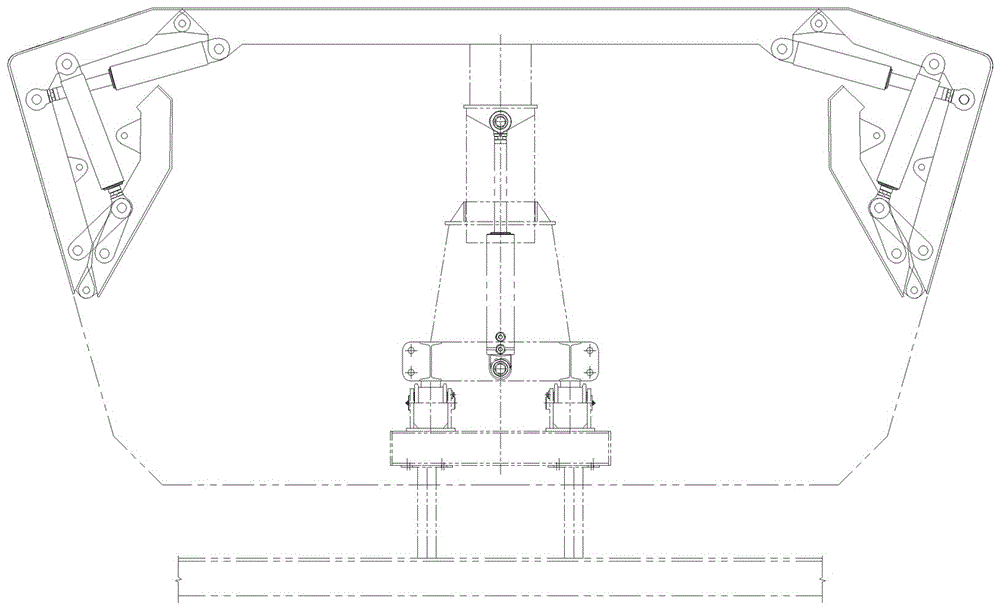

[0039] Embodiment two, such as Figure 5 to Figure 7 As shown, the formwork system of this embodiment includes a top mold and a first upper movable mold 2a, a second upper movable mold 2b and a lower movable mold hinged symmetrically on both sides of the top mold in turn, and the adjacent templates are hinged as a whole. Oil cylinders are respectively hinged between the top mold and the first upper movable mold, between the first upper movable mold and the second upper movable mold, and between the second upper movable mold and the lower movable mold, wherein the first upper movable mold and the second upper movable mold The oil cylinder between the upper moving die is in Figure 5 to Figure 7 None are shown. The hinge position between the two ends of each oil cylinder and the corresponding formwork is based on when the formwork system is folded, the oil cylinder is almost close to the formwork.

[0040] The link mechanism is hinged between the second upper movable mold and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com