Novel continuous mixing machine structure

A kneader and kneading technology, applied in the field of new continuous kneader structure, can solve the problems of inconvenient change of rubber materials, low degree of automation, low production efficiency, etc. High-level, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with specific embodiments.

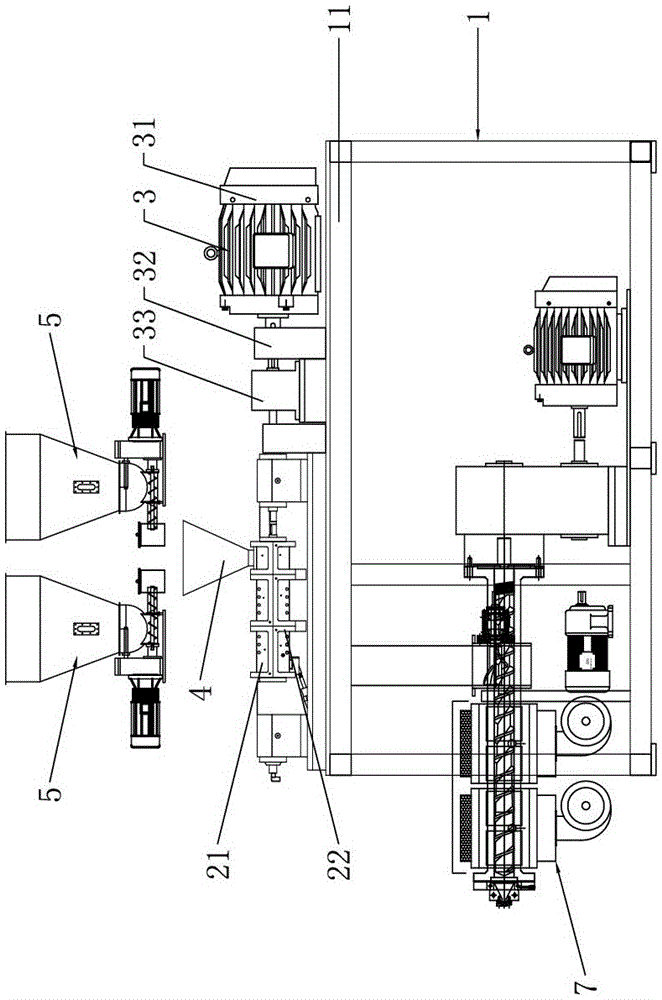

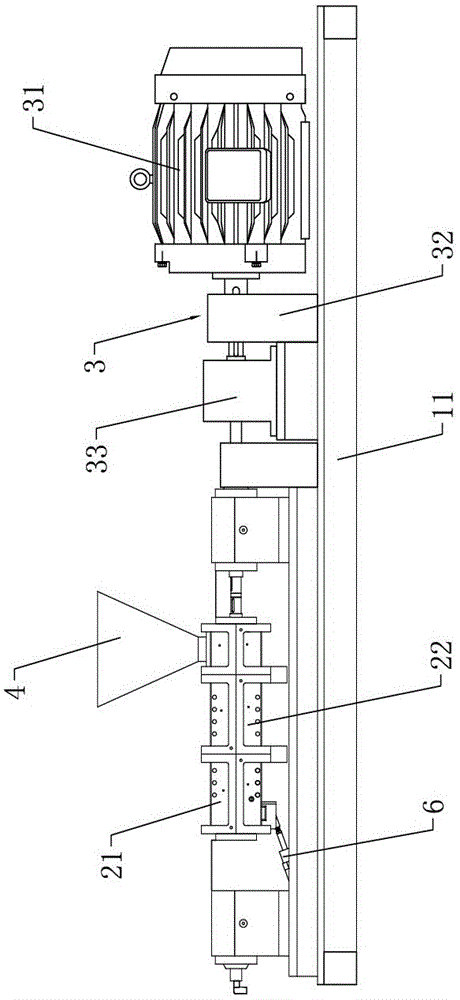

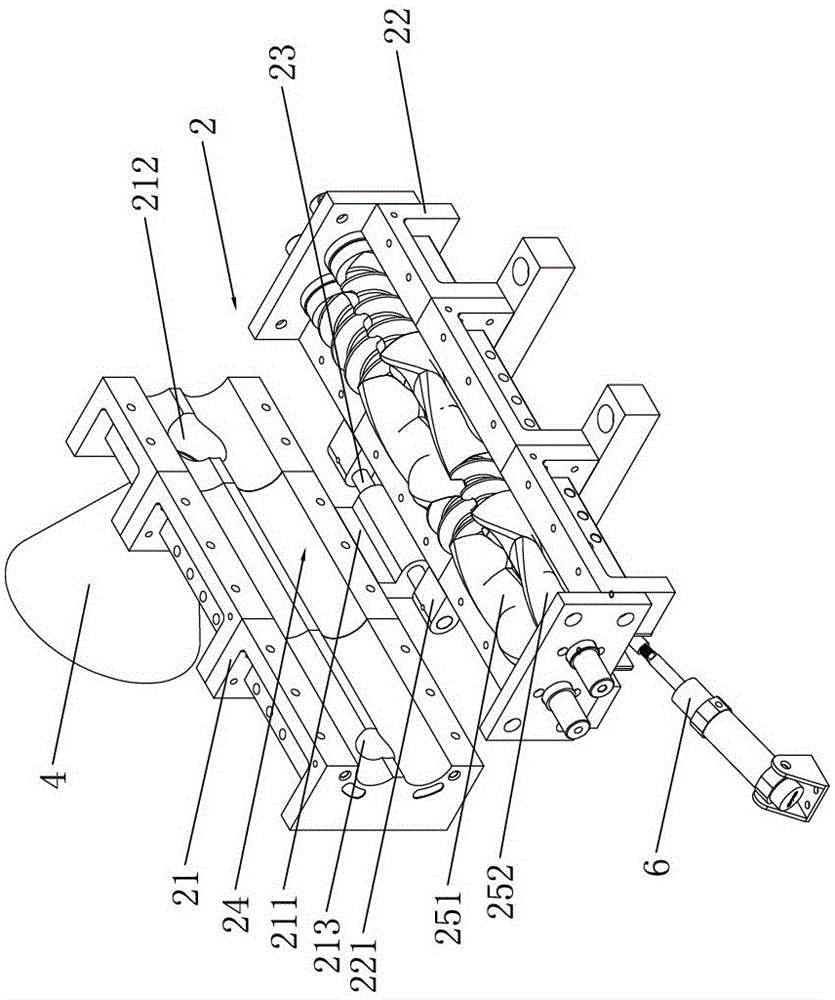

[0036] like Figure 1 to Figure 4 As shown, a new continuous mixer structure includes a frame 1, the upper end of the frame 1 is provided with a fixed support plate 11 arranged horizontally and horizontally, and the upper surface of the fixed support plate 11 is equipped with a mixing host 2 , the mixing host 2 includes a lower mixing shell 22 and an upper mixing shell 21 installed on the upper side of the lower mixing shell 22, the lower mixing shell 22 is screwed to the fixed support plate 11, and the lower mixing The rear surface of the housing 22 is provided with a lower hinged seat 221 protruding backward, and the rear surface of the upper mixing shell 21 is provided with an upper hinged seat 211 protruding backward. The upper hinged seat 211 and the lower hinged seat 221 Hinged by the pivot 23, the mixing host 2 is formed with a mixing chamber 24 in the shape of an inverted ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap