Deep tube product mold provided with movable core and working method of mold

A technology for movable cores and products, which is applied to household appliances, tubular items, and other household appliances, etc., can solve the problems of the end of the core, affecting the accuracy of products, and improving the scrap rate, etc., and achieves reliable positioning, reasonable structural design, The effect of easy parting and demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

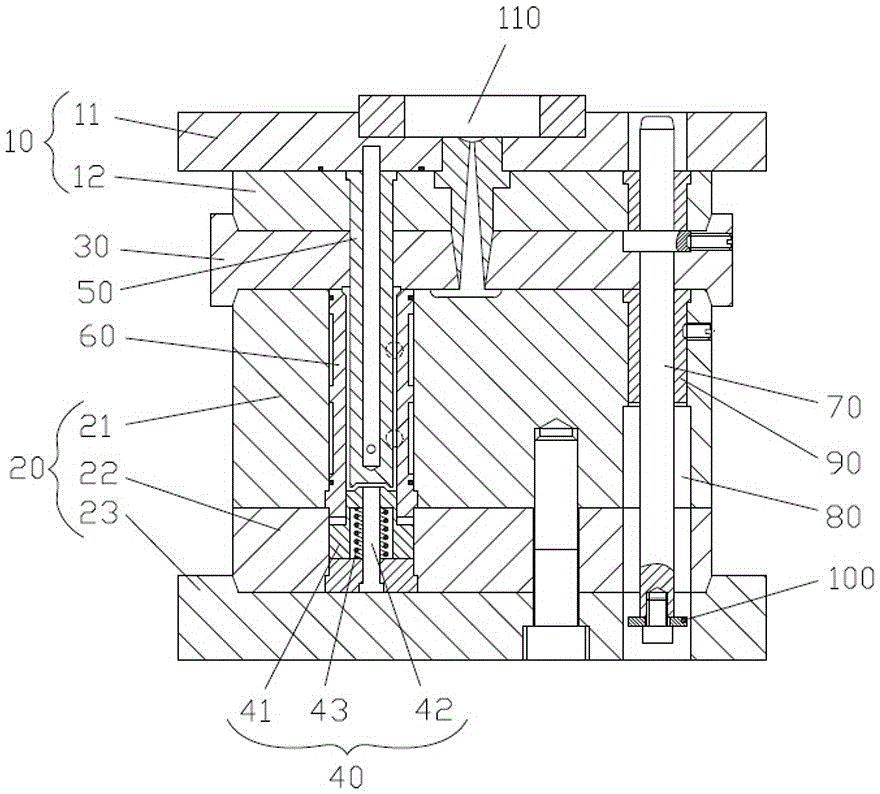

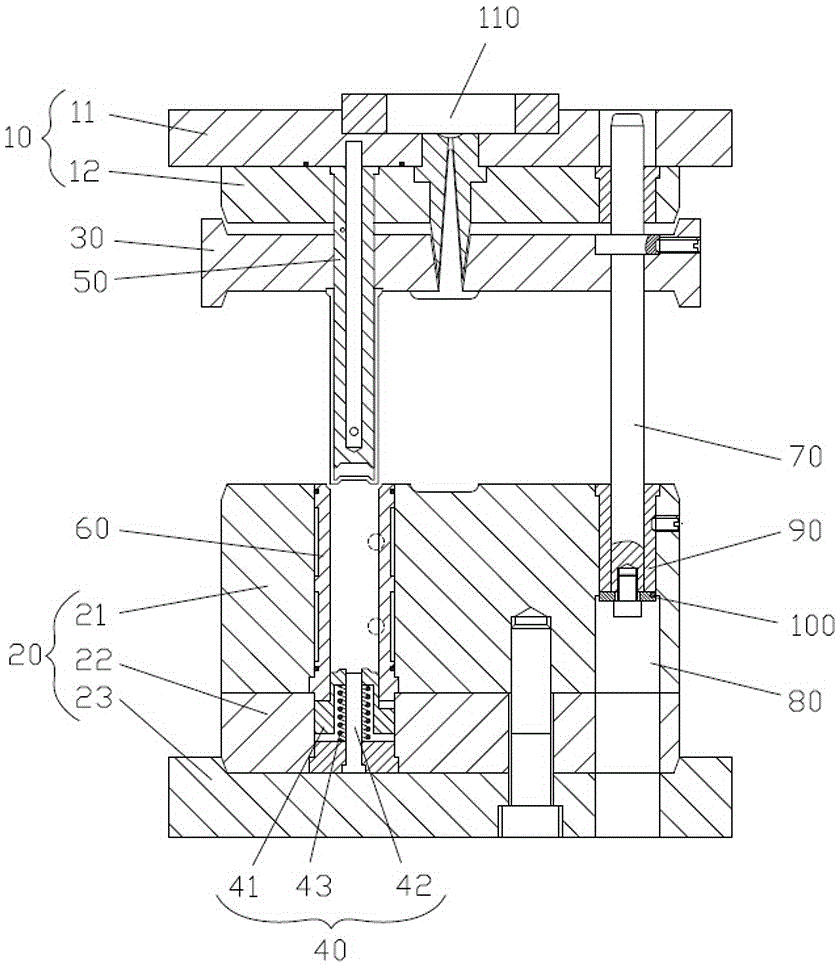

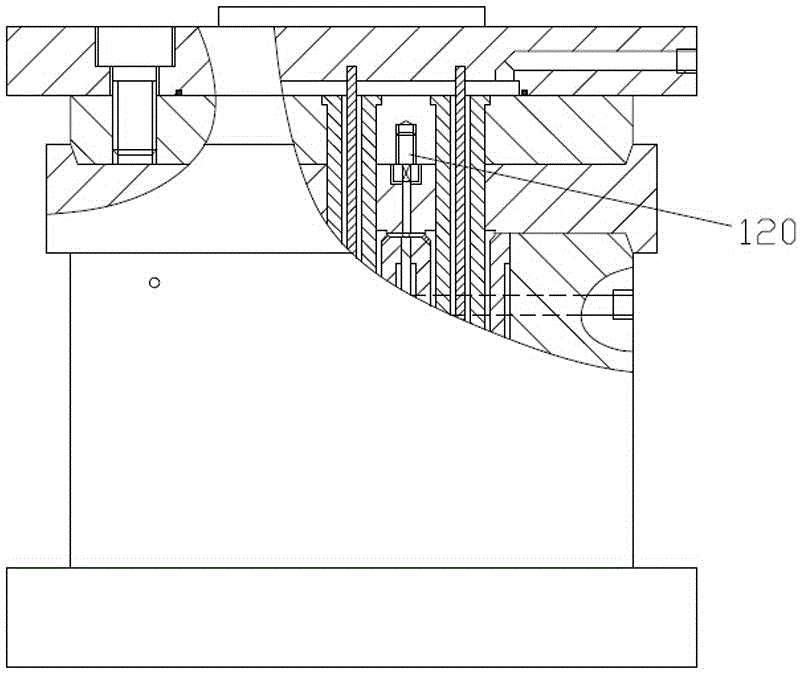

[0024] Such as Figure 1~4 As shown, a deep cylinder product mold with a movable core includes a fixed mold assembly 10 and a movable mold assembly 20, and a push plate 30 is arranged between the fixed mold assembly 10 and the movable mold assembly 20, so The contact surface between the push plate 30 and the movable mold assembly 20 is a parting surface, the movable mold assembly 20 is provided with a mold cavity, and the end of the mold cavity away from the fixed mold assembly 10 is provided with a telescopic movable A core 40, a fixed core 50 is connected in series between the fixed mold assembly 10, the push plate 30 and the movable mold assembly 20, and one end of the fixed core 50 is fixedly connected with the fixed mold assembly 10. The other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com