Processing technology for PTFE hollow sphere

A processing technology and PTFE technology, applied in the field of plastic processing, can solve the problems of complex molds and equipment, low precision of PTFE hollow balls, and inability to automatically take off, etc., and achieve the effect of high dimensional and shape accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

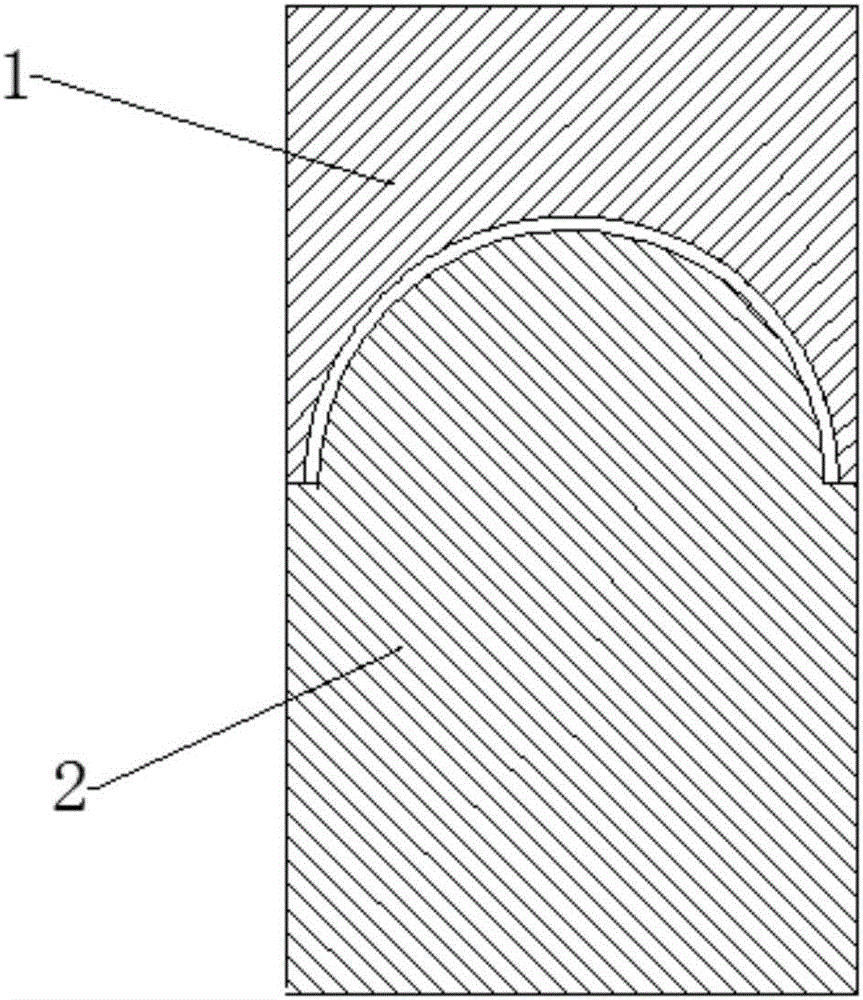

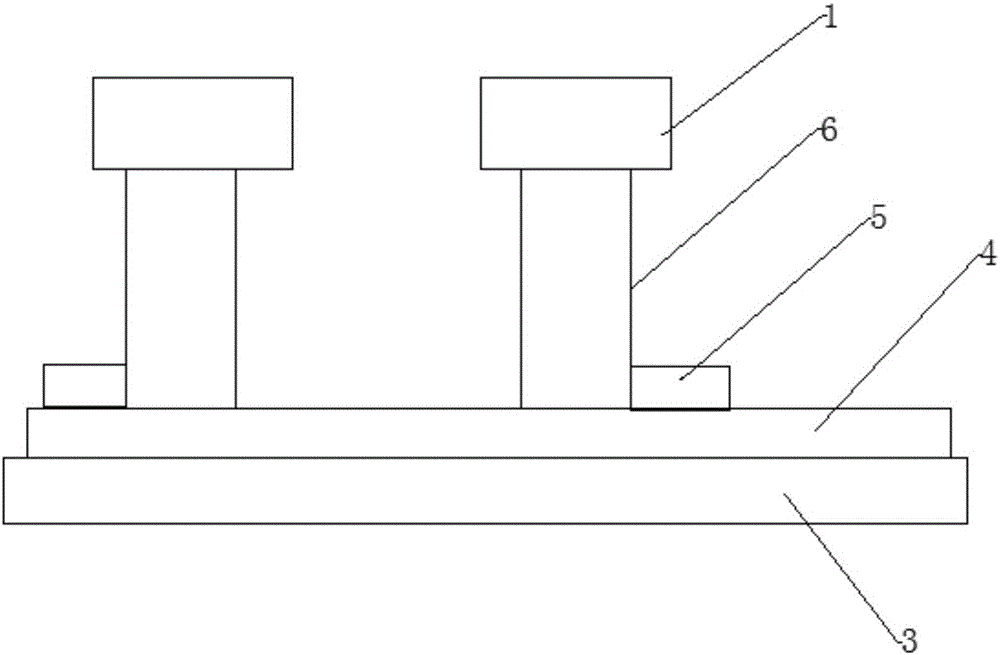

[0016] First make as figure 1 Two sets of hemispherical molds are shown, each set of hemispherical molds includes a hemispherical male mold 2 and a hemispherical female mold 1, and PTFE raw materials are poured into the hemispherical molds for compression molding. The molding temperature is 260°C, and two PTFE hemispherical shell, remove the hemispherical male mold, and then install the two PTFE hemispherical shells together with the hemispherical female mold 1 figure 2 On the docking device, the docking device is installed in an oven, and the docking device includes a base 3, a linear guide rail 4 is installed on the base 3, two hemispherical female mold holders 6 are installed on the linear guide rail 4, two hemispherical The female mold holders 6 are all connected to the driving device 5, and the hemispherical female mold holders 6 are driven to move on the linear guide rail 4 through the driving device 5, and a docking pressure sensor is also provided. The two PTFE hemis...

Embodiment 2

[0018] First make as figure 1 Two sets of hemispherical molds are shown, each set of hemispherical molds includes a hemispherical male mold 2 and a hemispherical female mold 1, PTFE raw materials are poured into the hemispherical molds for compression molding, and the molding temperature is 330°C to obtain two PTFE hemispherical shell, remove the hemispherical male mold, and then install the two PTFE hemispherical shells together with the hemispherical female mold 1 figure 2 On the docking device, the docking device is installed in an oven, and the docking device includes a base 3, a linear guide rail 4 is installed on the base 3, two hemispherical female mold holders 6 are installed on the linear guide rail 4, two hemispherical The female mold holders 6 are all connected to the driving device 5, and the hemispherical female mold holders 6 are driven to move on the linear guide rail 4 through the driving device 5, and a docking pressure sensor is also provided. The two PTFE ...

Embodiment 3

[0020] First make as figure 1 Two sets of hemispherical molds are shown, each set of hemispherical molds includes a hemispherical male mold 2 and a hemispherical female mold 1, PTFE raw materials are poured into the hemispherical molds for compression molding, and the molding temperature is 290°C to obtain two PTFE hemispherical shell, remove the hemispherical male mold, and then install the two PTFE hemispherical shells together with the hemispherical female mold 1 figure 2 On the docking device, the docking device is installed in an oven, and the docking device includes a base 3, a linear guide rail 4 is installed on the base 3, two hemispherical female mold holders 6 are installed on the linear guide rail 4, two hemispherical The female mold holders 6 are all connected to the driving device 5, and the hemispherical female mold holders 6 are driven to move on the linear guide rail 4 through the driving device 5, and a docking pressure sensor is also provided. The two PTFE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com