High-strength water-resistant breathable non-woven fabric

A technology of non-woven fabric and non-woven fabric layer, which is applied in the field of high-strength water-blocking and breathable non-woven fabrics, which can solve the problems of no water-blocking protection, low structural strength, and small weighing weight, etc., to achieve improved structural strength and simple structure , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

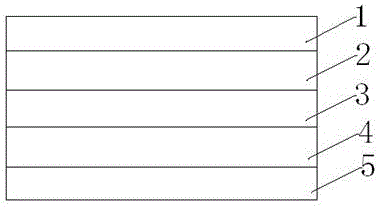

[0019] A high-strength water-blocking and breathable non-woven fabric, comprising: a first non-woven fabric layer 1 , a reinforced water-blocking and breathable layer 2 and a second non-woven fabric layer 3 from top to bottom.

[0020] Wherein, the first non-woven fabric layer 1 and the second non-woven fabric layer 3 are both spun-bonded non-woven fabrics.

[0021] The reinforced waterproof and breathable layer 2 is a glass fiber-reinforced polyethylene film layer with a thickness of 0.05-0.15mm, and the weight percentage of glass fiber is 5-15%. The hole 4, the diameter of the vent hole 4 is larger than the diameter of a single water vapor molecule and smaller than the diameter of a water molecule, so that the external water cannot enter the non-woven fabric belt, and at the same time, the non-woven fabric can realize water vapor penetration with the outside world, so that To achieve the purpose of ventilation.

Embodiment 2

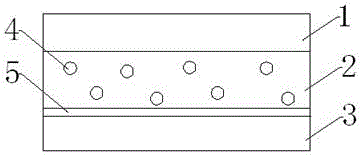

[0023] The difference from Example 1 is that there is also a layer of reinforced fiber mesh 5 between the reinforced water-blocking and breathable layer 2 and the second non-woven fabric layer 3, which is made of bamboo fiber or wood fiber mesh, and the mesh of the fiber mesh is Rectangular, square or rhombus, the grid diameter is 1-5cm.

[0024] The fiber net plays a role in strengthening and supporting the whole non-woven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap