Rear torsion beam assembly of vehicle

A technology for torsion beams and vehicles, applied in vehicle components, interconnection systems, suspensions, etc., can solve problems such as easy cracking, affecting service life and safety, and achieve the effect of avoiding cracking, solving stress concentration, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

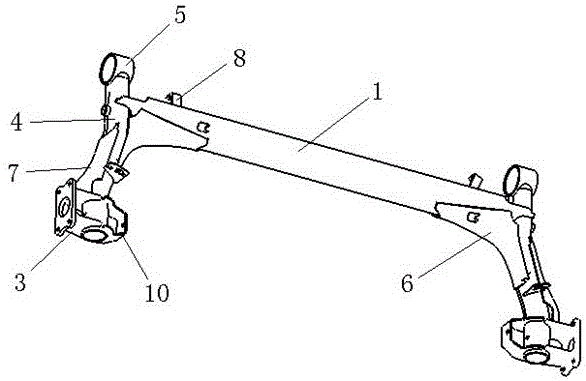

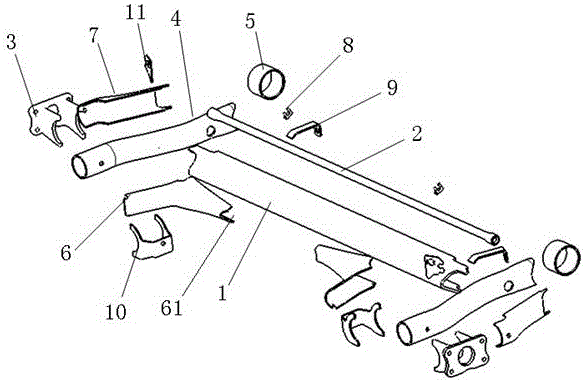

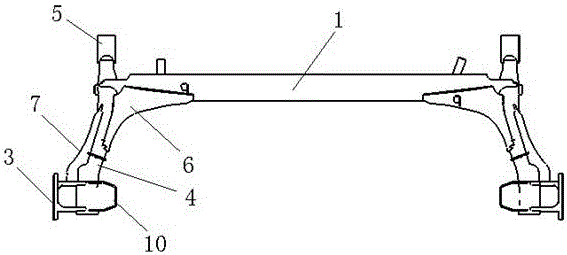

[0023] As shown in the figure, the rear torsion beam assembly of the vehicle in this embodiment includes a crossbeam 1, a torsion bar 2, hub supports 3 on both sides, and a longitudinal arm 4. The front end of the longitudinal arm 4 is provided with a bushing sleeve 5, and the rear end It is welded and fixed with the hub support 3 on the corresponding side; the bushing sleeve 5 is cut from a circular steel pipe, and the front end of the longitudinal arm 4 is cut into an arc shape by machining, so that it can be closely attached to the surface of the bushing sleeve 5; The axis of the bushing 5 is parallel to the beam 1 , which is perpendicular to the trailing arm 4 .

[0024] The two ends of the beam 1 and the torsion bar 2 are respectively welded and fixed to the corresponding side of the longitudinal arm 4, wherein the torsion bar 2 is a solid bar, and the diameter of the torsion bar 2 gradually decreases from the two ends to the middle, and the surface of the torsion bar 2 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com