Star type feeding valve

A star-shaped feeding and feeding port technology, applied in conveyors, rotary conveyors, transportation and packaging, etc., can solve problems such as poor sealing effect, affecting continuous and uniform discharge of materials, and increased equipment maintenance costs. Achieve effective sealing and eliminate gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

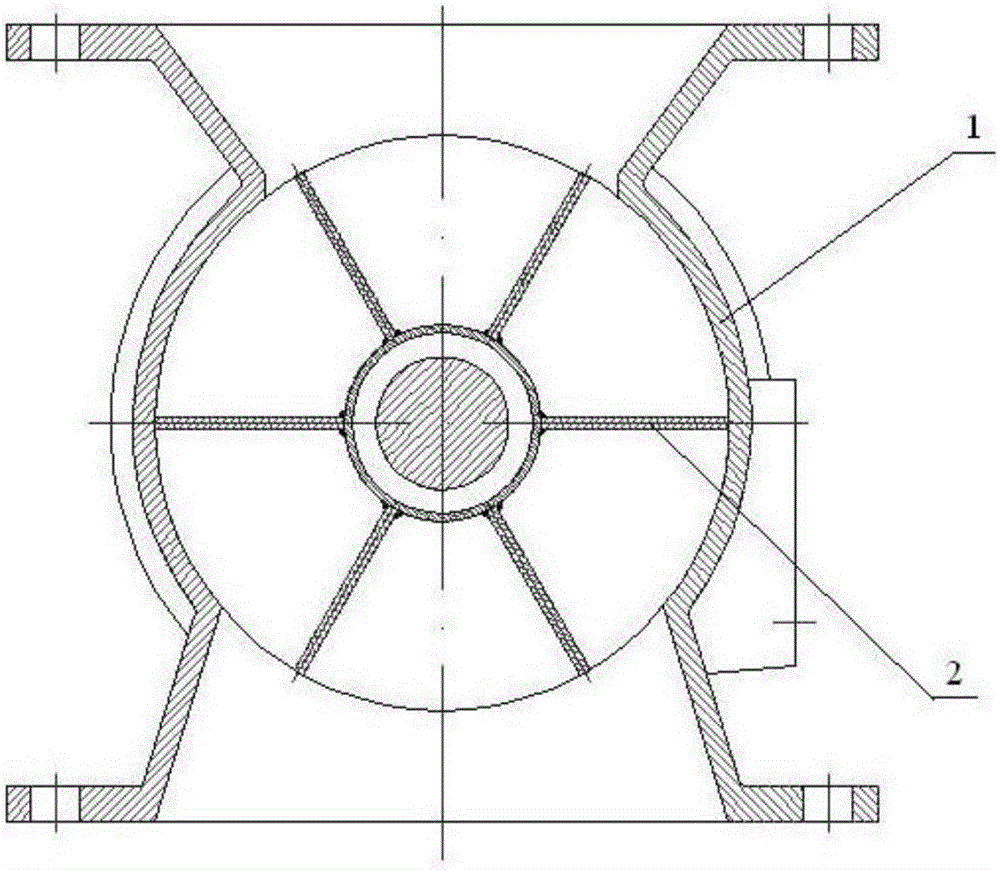

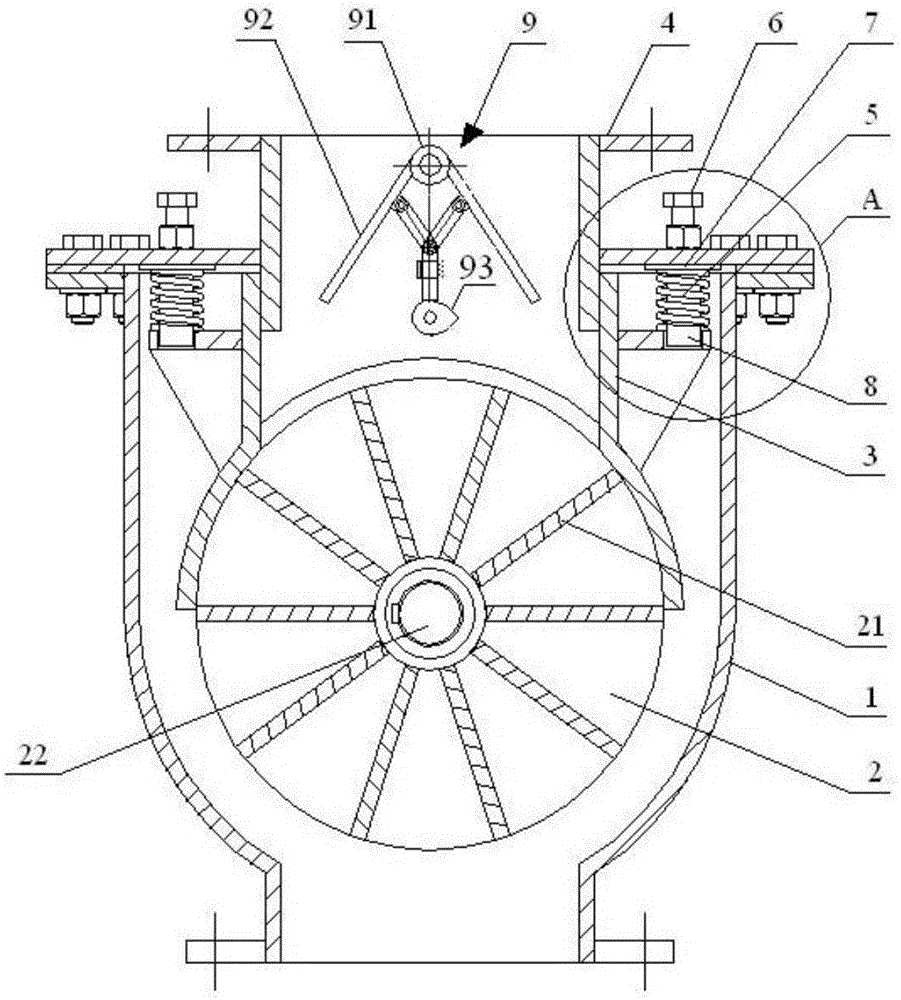

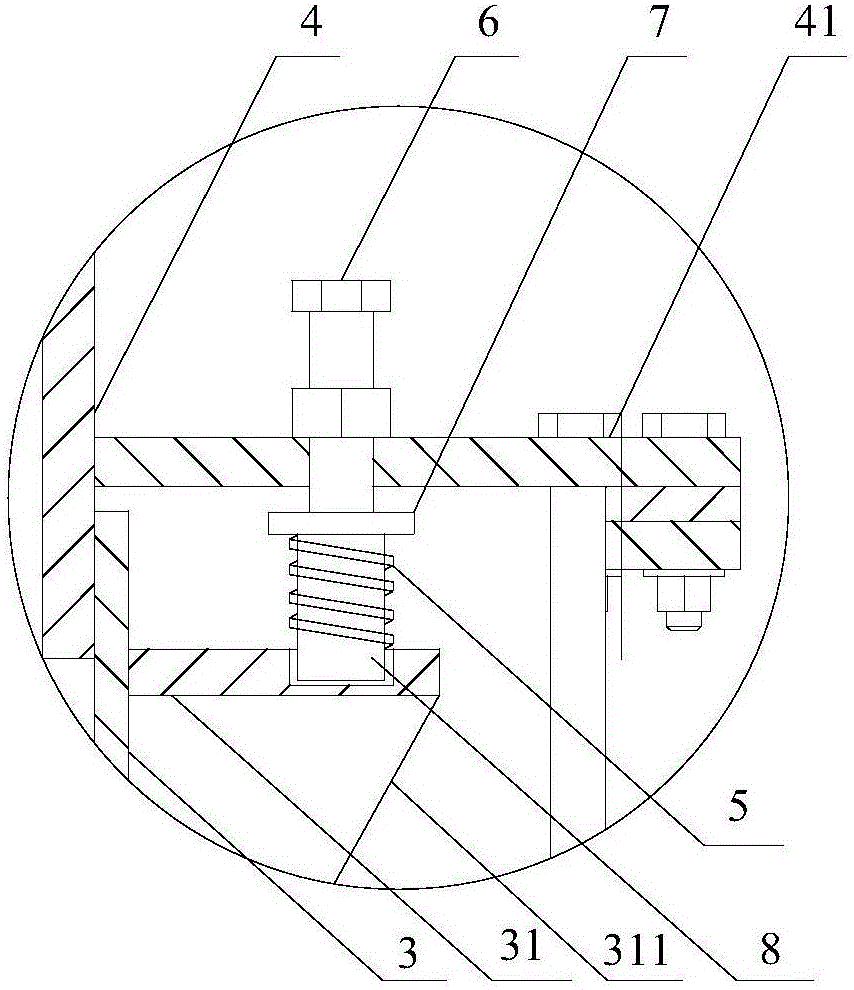

[0028] Please refer to Figure 2-5 , figure 2 It is a schematic cross-sectional structure diagram of a specific embodiment of the star feed valve provided by the present invention, image 3 for figure 2 Partial enlarged view of part A in the middle, Figure 4 for figure 2 Schematic diagram of the structure of the middle opening adjustment device, Figure 5 for figure 2 Schematic diagram of the overall structure of the star feed valve.

[0029] like figure 2 As shown, the present invention provides a star feed valve, comprising a housing 1 and a rotor impeller 2 located in the housing 1, the housing 1 has an inlet and an outlet, and the rotor impeller 2 is provided with a plurality of Web 21. Both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com