Cheese dyeing wastewater adjusting tank

A technology for dyeing wastewater and bobbins, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficulty in mastering, poor effect of adjusting pools, and failure to meet production requirements, and achieve high efficiency. Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

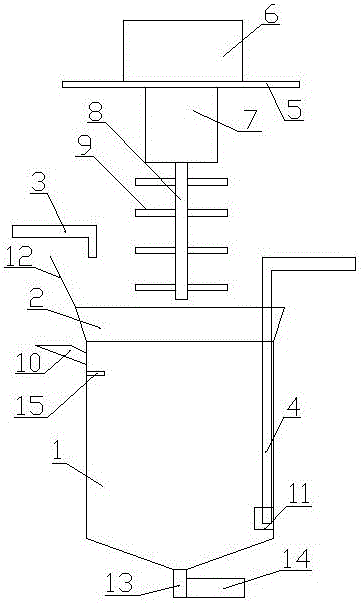

[0012] Such as figure 1 As shown, the present embodiment provides a cheese dyeing wastewater regulating pool, including a pool body 1, the top of the pool body 1 is an open mouthpiece 2, and a water inlet pipe 3 is arranged on the top left side of the top of the open mouthpiece 2, and the pool body 1 is provided with a suction pipe 4 on the right side, and the suction pipe 4 protrudes from the opening mouth to the right side of the pool body 1; a top plate 5 is provided above the pool body 1, a down-moving motor 6 is provided on the top of the top plate 5, and a motor 6 is provided on the bottom of the top plate 5. Stirring motor 7, a stirring rod 8 is connected to the bottom of the stirr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap