Prefabricated housing made from straw composite material

A technology of composite materials and integrated houses, applied in building materials, building components, buildings, etc., can solve problems such as low strength and complex structure, and achieve high strength, good earthquake resistance and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

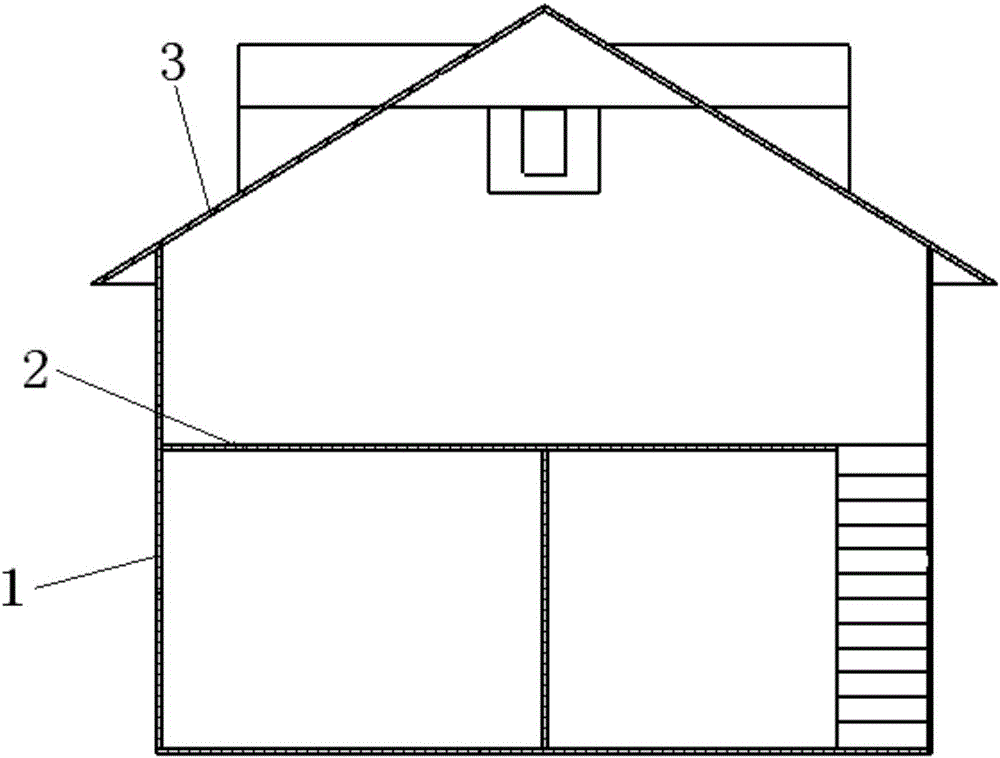

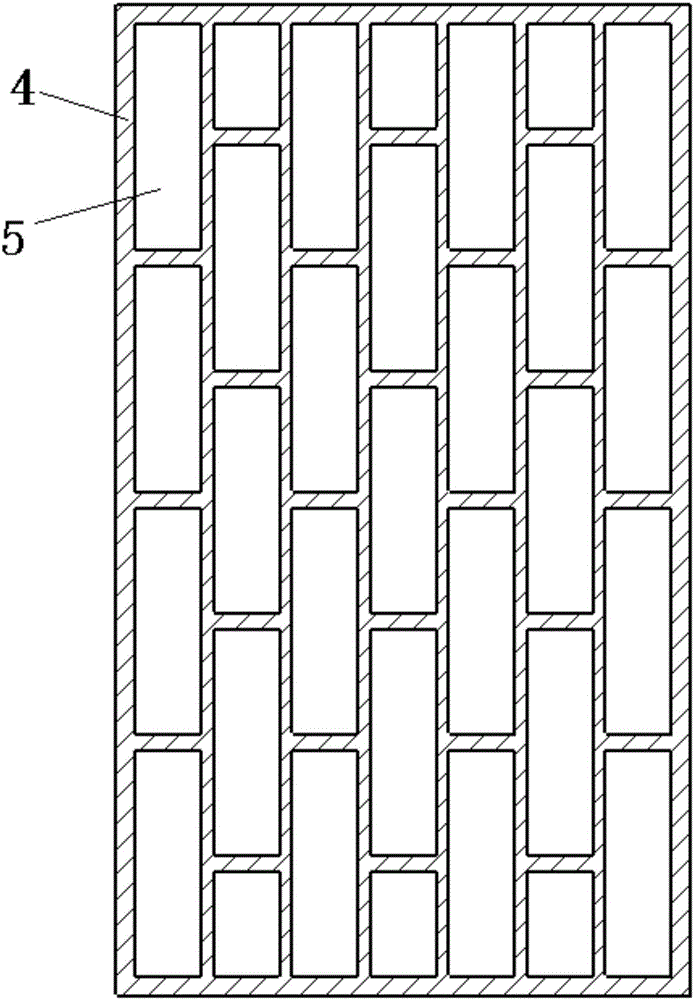

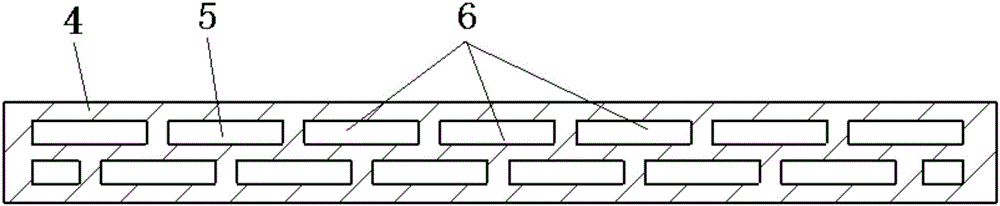

[0015] The integrated house made of straw composite material includes wall panel 1, floor panel 2 and roof panel 3, wall panel 1, floor panel 2 and roof panel 3 are connected by adhesive material 4, wall panel 1, floor panel 2 and roof panel 3 all include adhesive bonding material 4 and a plurality of plank strips 5, the plank strips 5 are arranged at intervals to form plank strip layers 6, and the bonding material 4 covers the plank strip layers 6 and fills the gaps between the plank strips 5;

[0016] The raw materials of the bonding material 4 include by weight: 15% to 25% of magnesium oxide, 12% to 15% of magnesium chloride, 0.3% to 0.52% of modifier, 0.68% to 0.88% of binder, and 0.38% to 0.58% of setting agent. %, 30% to 35% of straw, 5% to 6.5% of glass reinforced fiber; the balance is water.

[0017] The manufacturing method of the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com